Truss-string structure with additional standby cables

A string truss and truss technology, which is applied to the string truss structure and its construction field for adding equipment cables, can solve problems such as collapse, low redundancy of string truss structures, casualties and economic losses, etc., and achieve shock relief, Improve the ability of anti-successive collapse and improve the effect of internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further specifically described below in conjunction with the embodiments and the accompanying drawings.

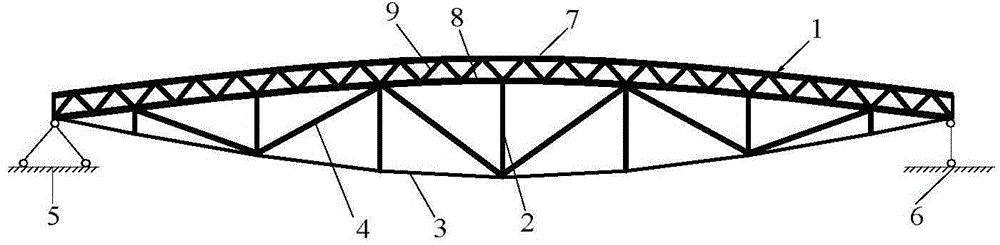

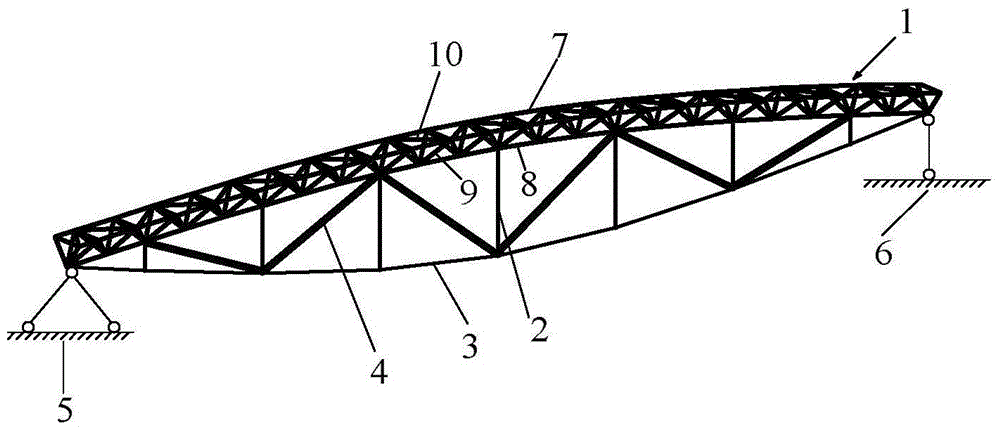

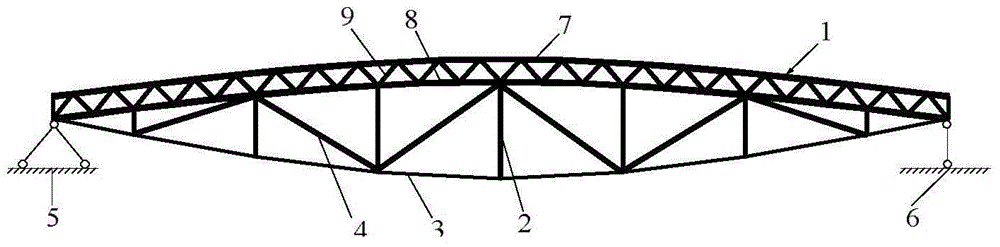

[0030] N is taken as 3, that is, a single chord truss structure with 7 struts in the middle is set as an example to illustrate the implementation method of the chord truss structure for equipment extension provided by the present invention. As shown in Figures 1 to 4, a string truss structure for adding cables for equipment in this embodiment is composed of a traditional string truss and a central spare cable 4, and the central spare cable 4 is symmetrically arranged on the upper truss of the traditional string truss 1 and the lower cable 3 between.

[0031] The chord truss of the present invention, as shown in Figures 1 to 4, includes an upper truss 1, seven middle struts 2, a lower stay cable 3, a fixed hinge support 5, and a sliding hinge support 6. Among them, the upper truss 1 is an upright quadrangular pyramidal space arch truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com