Construction method for filling gravel in horizontal oil well pipe

A technology of gravel filling and construction method, which can be used in earth-moving drilling, wellbore/well components, cleaning appliances, etc., and can solve the problems of long construction period and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

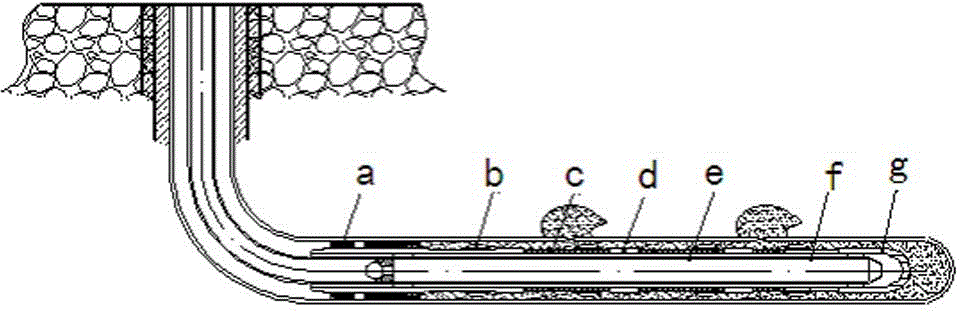

[0024] combined with figure 1 , a kind of gravel packing construction method in oil field horizontal well pipe that the present invention mentions, comprises the following steps:

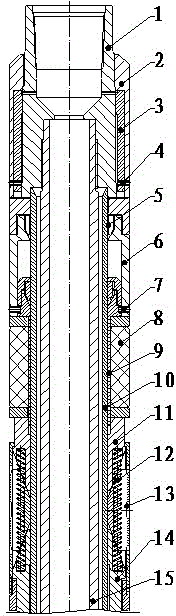

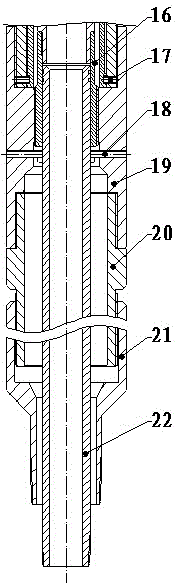

[0025] a. Bottom gravel packing valve g, precision sand filter pipe c, meltable centralizer b, two-way hot-melt thermal stress compensator d, unsealable drop-in suspension packer a, flushing pipe e, filling server f and oil pipe Connect together according to the design sequence, and go down to the predetermined position in the casing; among them, the bottom gravel filling valve g, the precision sand filter pipe c, the meltable centralizer b, the two-way hot-melt thermal stress compensator d and the filling server f are existing Technical products, no more details;

[0026] b. Circulating well flushing, throwing hollow steel balls to pressurize, seat seal and detachable suspension packer 1;

[0027] c. Unsealable disposable suspension packer 1 inspection, unsealable disposable suspension packer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com