Self-suspension proppant and preparation method thereof and construction method

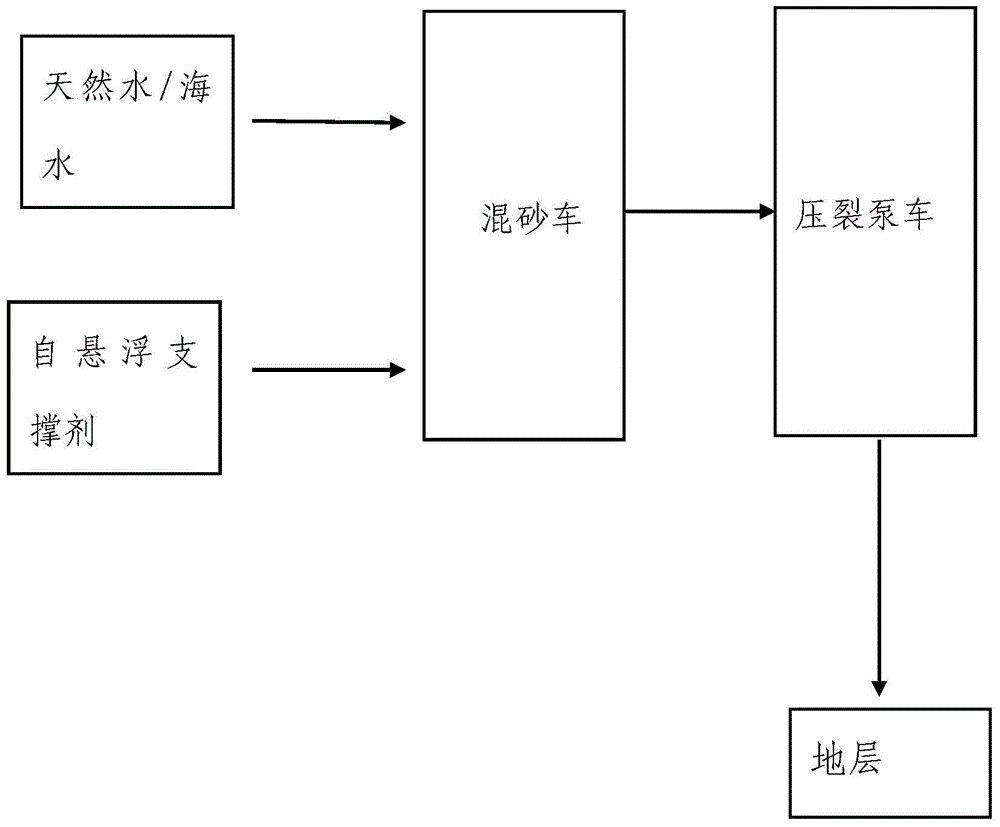

A construction method and proppant technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of reduced oil conduction capacity of reservoirs, inconvenient construction, contaminated reservoirs, etc., to reduce manpower and other costs , increase convenience and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

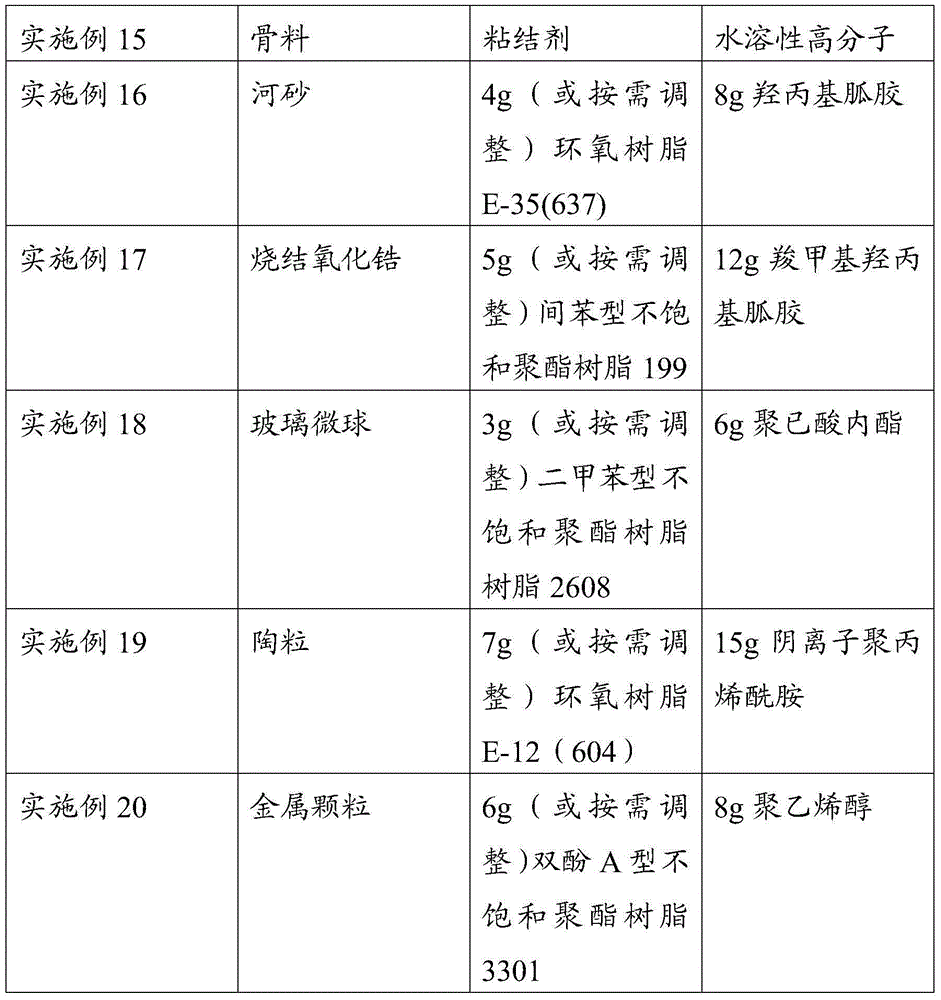

[0099] Preparation method of self-suspending proppant

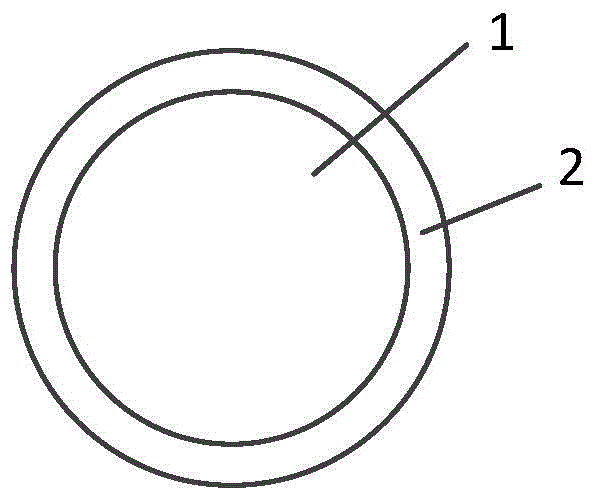

[0100] It can be seen from the foregoing that the self-suspending proppant of the present invention can at least have the following structural forms:

[0101] 1. Aggregate + water-soluble polymer material

[0102] 2. Aggregate + binder + water-soluble polymer material

[0103] 3. Aggregate + binder + curing agent + water-soluble polymer material

[0104] 4. Aggregate + binder + water-soluble polymer material + curing agent

[0105] 5. Aggregate + binder + curing agent + water-soluble polymer material + binder

[0106] In structural forms 1-5, the aggregate refers to natural hard particles or artificially fired hard particles, wherein, natural hard particles are such as metal particles or natural sand, and natural sand includes but not limited to aeolian Sand, river sand, sea sand or mixtures thereof; artificially fired hard particles including but not limited to ceramsite, sintered bauxite, sintered alumina, sintered ...

Embodiment 1

[0153] Example 1 Self-suspending proppant

[0154] The preparation method of the proppant described in this example is as follows:

[0155] (1) Take 20-40 mesh 1kg quartz sand as the aggregate for use;

[0156] (2) heating to 200°C, adding 10 g of polycaprolactone to the aggregate, and mixing uniformly;

[0157] (3) Cooling, crushing, and sieving the mixture in the above step (2) to obtain the final product.

Embodiment 2

[0158] Example 2 Self-suspending proppant

[0159] The preparation method of the proppant described in this example is as follows:

[0160] (1) Take 1kg glass microspheres of 50-100 meshes as the aggregate for use;

[0161] (2) Heating to 220°C, adding 15g of guar gum to the aggregate, and mixing uniformly;

[0162] (3) Cooling, crushing, and sieving the mixture in the above step (2) to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com