A thrust chamber collector with flow sharing function

A collector and thrust chamber technology, applied in the field of liquid rocket engine design, can solve problems such as uneven pressure at the outlet of the collector and fluctuations in pressure distribution in the inlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

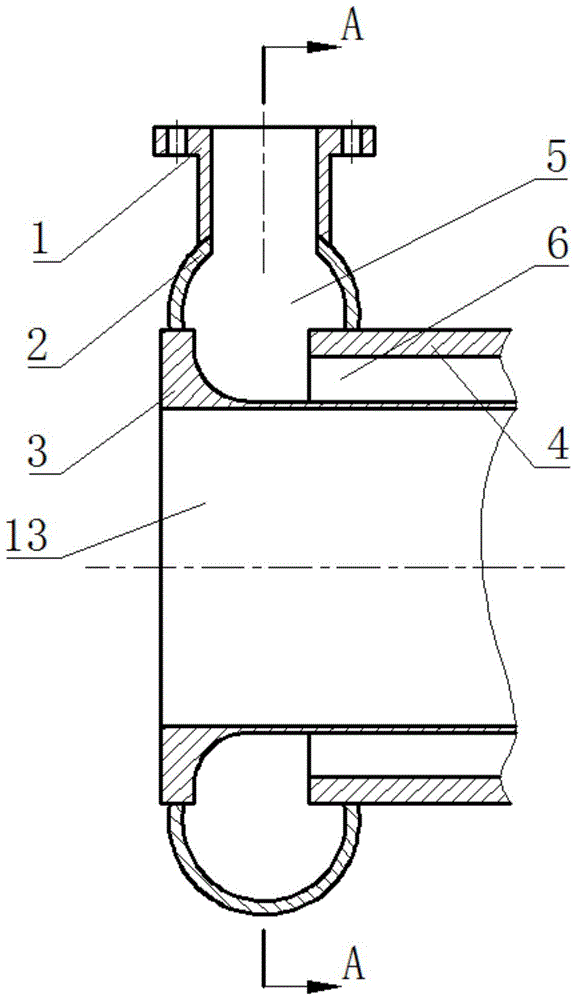

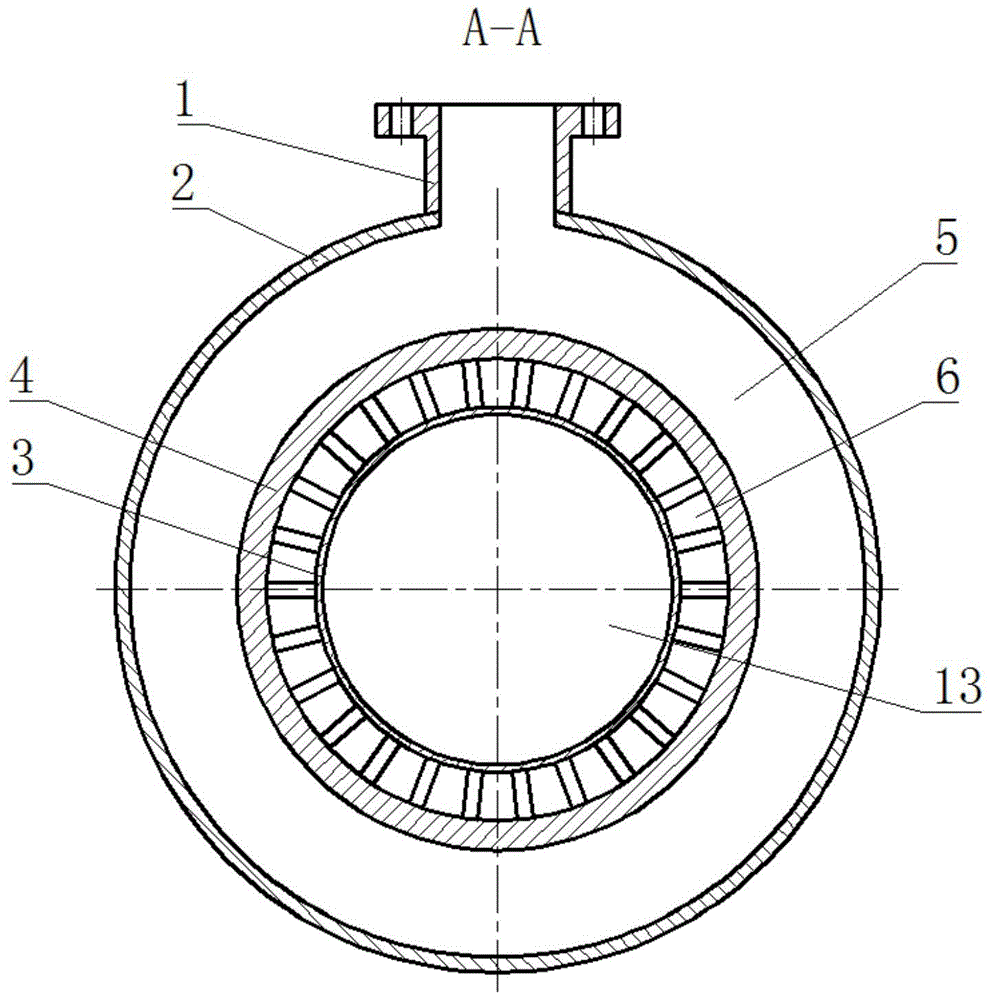

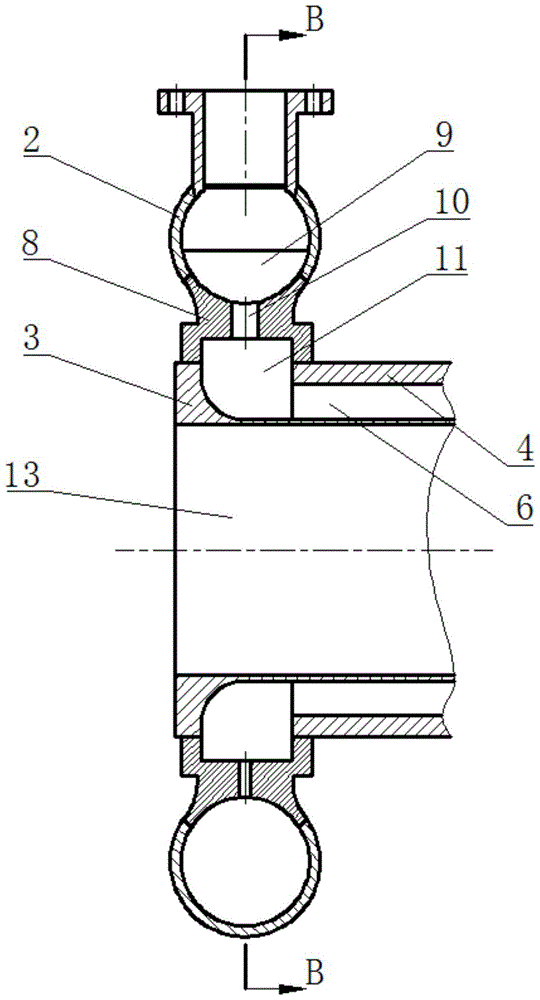

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as image 3 and Figure 4 As shown, the collector elbow 2 is an elbow surrounded by pipes with a circular cross-section, and an arc-shaped opening is processed on the inner side of the elbow, and an inlet is processed at any position on the outer circumference of the pipe. An expansion type inlet flange 7 is installed at the inlet, and a "human" shape deflector 12 is welded and fixed at the inlet.

[0021] Weld ring hole seat 8 on the arc opening of the inner side of pipe, described welding ring hole seat 8 is disk shape, and the shape of its section is as image 3 As shown, the outside of the cross-section is arc-shaped, which forms a complete circle with the cross-section of the collector elbow 2, and the inside of the cross-section has a shoulder structure, and the shoulder is fixedly welded to the inner inner wall 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com