LED lamp achieving current limiting by means of thermistor

An LED lamp and thermistor technology, applied in the field of lighting, can solve the problems of large drive circuit module volume, increase the overall volume of LED filament lamps, and large difference between LED filament lamps, etc., to achieve temperature protection function and improve user acceptance. , The effect of solving the heat dissipation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

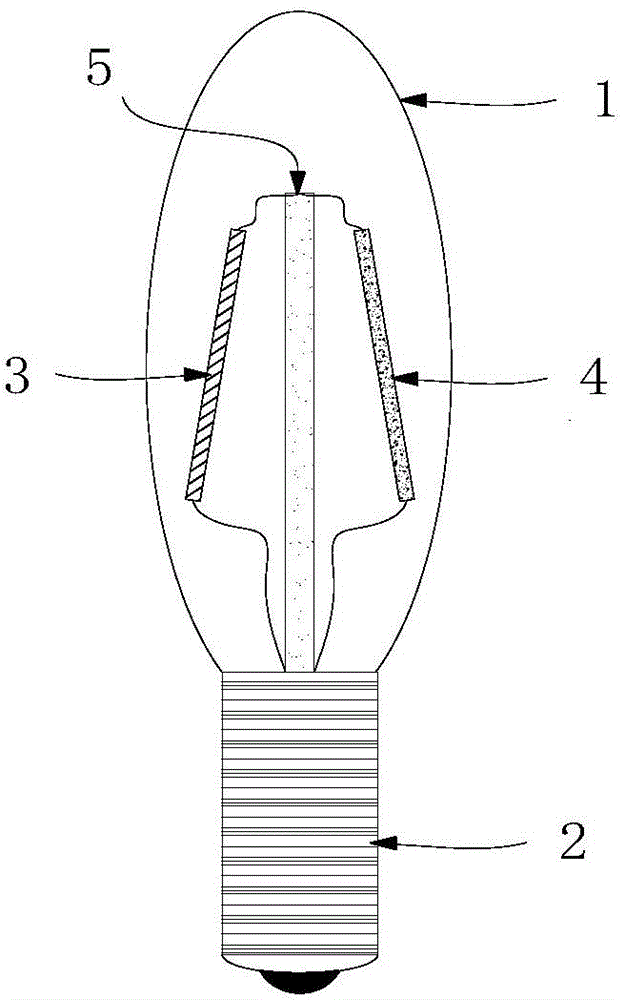

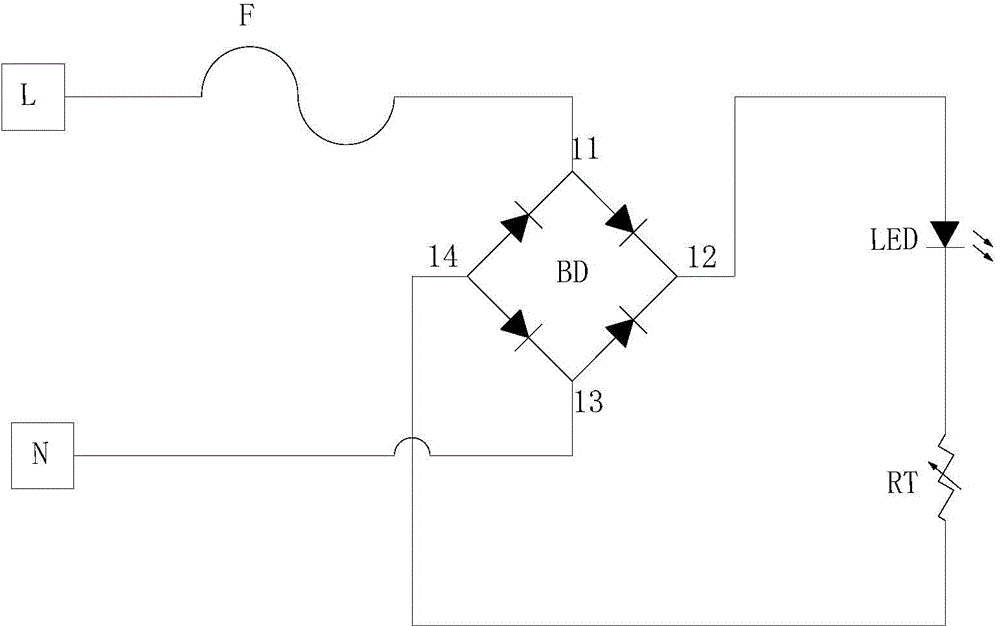

[0028] The LED lamp using the thermistor current limiting provided in the embodiment of the present invention can be applied to filament lamp products, mainly by using the thermistor in series with the LED filament to limit the current, and also by connecting the thyristor dimmer in series Then realize the function of LED filament dimming; because the thermistor connected in series with the LED filament is a miniaturized positive temperature coefficient thermistor, its resistance increases when the temperature rises to reduce the current in the circuit, thereby reducing Power, to keep the power of the LED filament within the rated range, that is, the positive temperature coefficient thermistor is used to limit the current flowing through the LED filament within the rated current range (to achieve a constant current effect), because the current-limiting thermistor is in A certain amount of power is lost during work, and as the current on the LED filament increases, the power los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com