Line scanning camera imaging method for object with variable thickness

A technology of line scan camera and thickness change, applied in the direction of measuring device, material analysis through optical means, instrument, etc., can solve the problems of complex structure, lower system imaging precision, few patents for adjusting imaging distance change, etc., and achieve increase The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

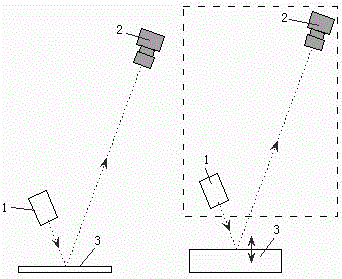

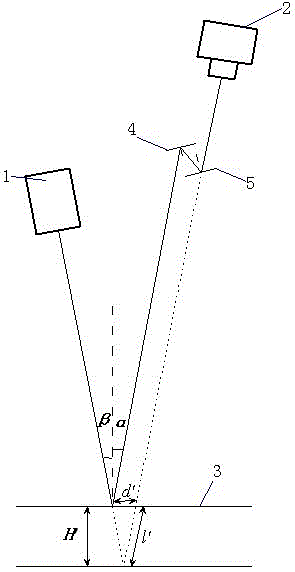

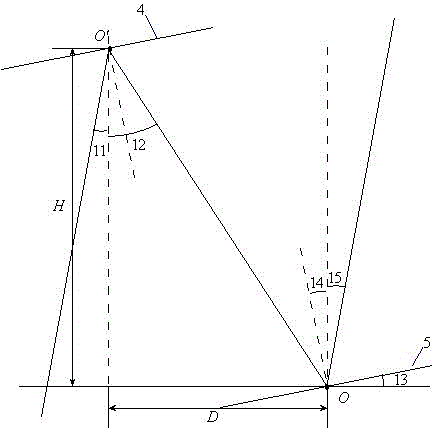

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] A line scan camera imaging method for object thickness changes. The camera 2 and the light source 1 form the imaging optical path of the detection system at a set angle, and a plane mirror group is arranged on the reflected optical path of the object to be imaged. The light is emitted from the light source 1 and passes through the imaging path. After surface 3 is reflected, enter camera 2 imaging after plane mirror group 4,5 again; Said plane mirror group comprises first plane mirror 4 and second plane mirror 5, and first plane mirror 4 and second plane mirror 5 reflection surfaces are opposite and parallel, first Plane mirror 4 and the second plane mirror 5 are elongated, and the first plane mirror 4 and the second plane mirror 5 are rotated with the length direction rotation axis of crossing width midpoint respectively, and the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com