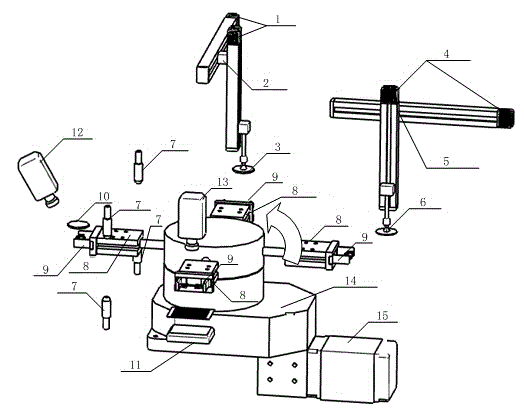

Online detecting device for defect of lens

A detection device and lens technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor lens pertinence and poor adaptability of lens size, etc., and achieve improved coverage and high integration , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

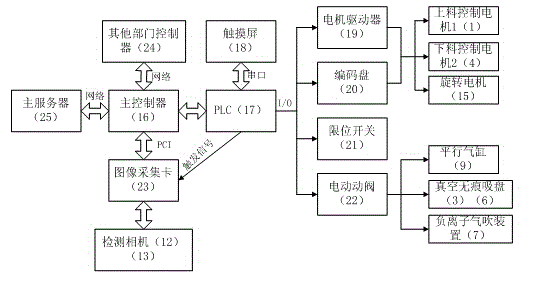

[0022] The lens defect detection process takes the four-station online detection of a single lens defect as an example. The implementation steps are as follows:

[0023] 1. The front-end feeding production line is ready, PLC17 sends a pulse signal for the feeding process through the motor driver 19, and the feeding control motor 1 moves in the X and Y directions to the unloading position of the front-end feeding production line;

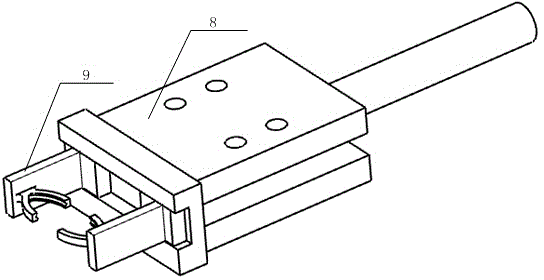

[0024] 2. PLC17 controls the electro-pneumatic valve 22 to generate negative pressure through the I / O port, so that the vacuum suction cup 3 for feeding the material will suck up the lens;

[0025] 3. The loading cross slide 2 moves through the lens to the position of the lens clamping jaw of the loading station, and the PLC17 controls the parallel cylinder 8 to perform the clamping task, and at the same time releases the negative pressure in the vacuum suction cup 3 for the material feeding, so that the lens is clamped by the lens Claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com