Automatic testing method for pH value of methylamine nitrate manufacturing procedure

A technology of methylamine nitrate and automatic testing, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., to achieve the effects of prolonging service life, improving accuracy and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

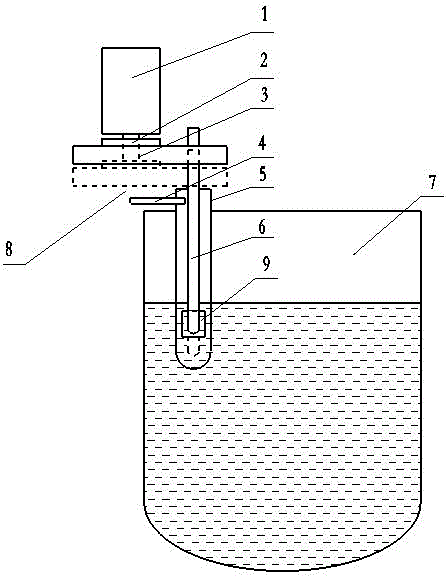

[0018] A method for automatically testing the pH value in the production process of methylamine nitrate, in which a pH value online detection device 8 is installed on the neutralization tank 7, an automatic flushing device 4 is installed on the pH value online detection device 8, and the pH value is activated when the reaction is approaching the end On-line detection device 8 completes the automatic detection of pH value by pH value on-line detection device 8; completes the flushing of on-line pH meter 6 in pH value on-line detection device 8 by automatic flushing device 4 after the end of the reaction, and simultaneously removes the remaining nitric acid Methylamine rinses away, ensuring safety.

[0019] Such as figure 1 As shown, the pH value on-line detection device 8 includes a transmission assembly 1, a pusher 2 connected to the transmission assembly, a clamping device 3 connected to the pusher, an online pH meter 6 installed on the clamping device, installed on A sheath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com