Substrate detection device and method

A substrate inspection and detection device technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as TFT damage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0086] The substrate inspection and detection device of the present invention makes the probe contact the terminal of the inspection target substrate positioned based on the outer shape, and conducts electrical inspection (inspection of electrode disconnection, short circuit, etc.) by checking whether there is continuity between the terminal and the probe.

[0087] In this embodiment, as an example of such a substrate inspection probe device, a TFT panel substrate of a liquid crystal display panel is used as an inspection target substrate, and the electrical inspection performed is a lighting inspection of the liquid crystal display panel. In addition, the substrate to be inspected by the substrate inspection probe device of the present invention is not limited to the TFT panel substrate of the liquid crystal display panel, as long as it requires electrical inspection such as disconnection and short circuit of electrodes.

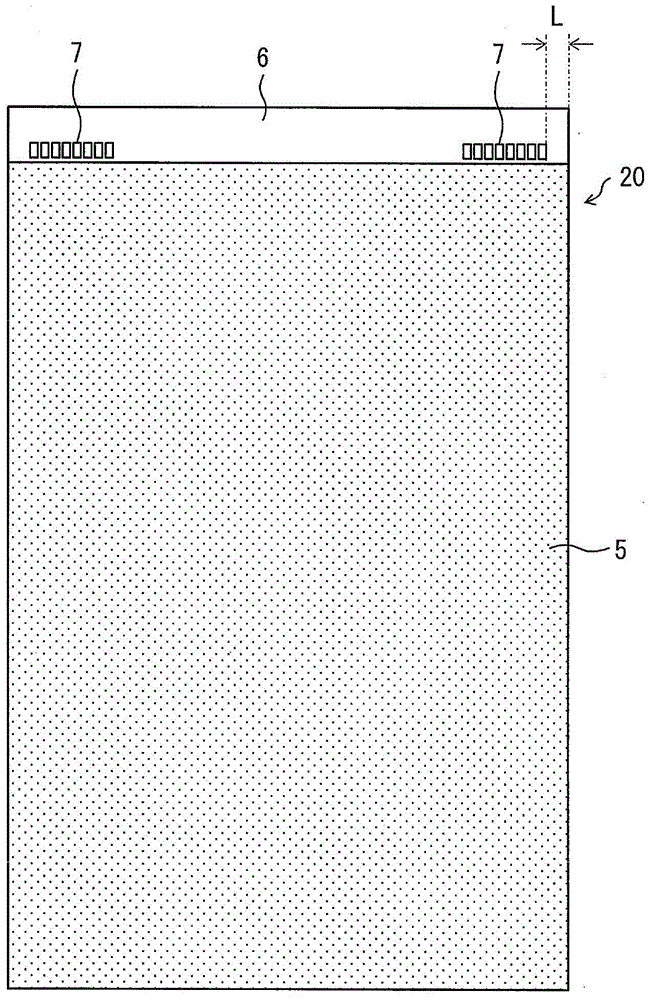

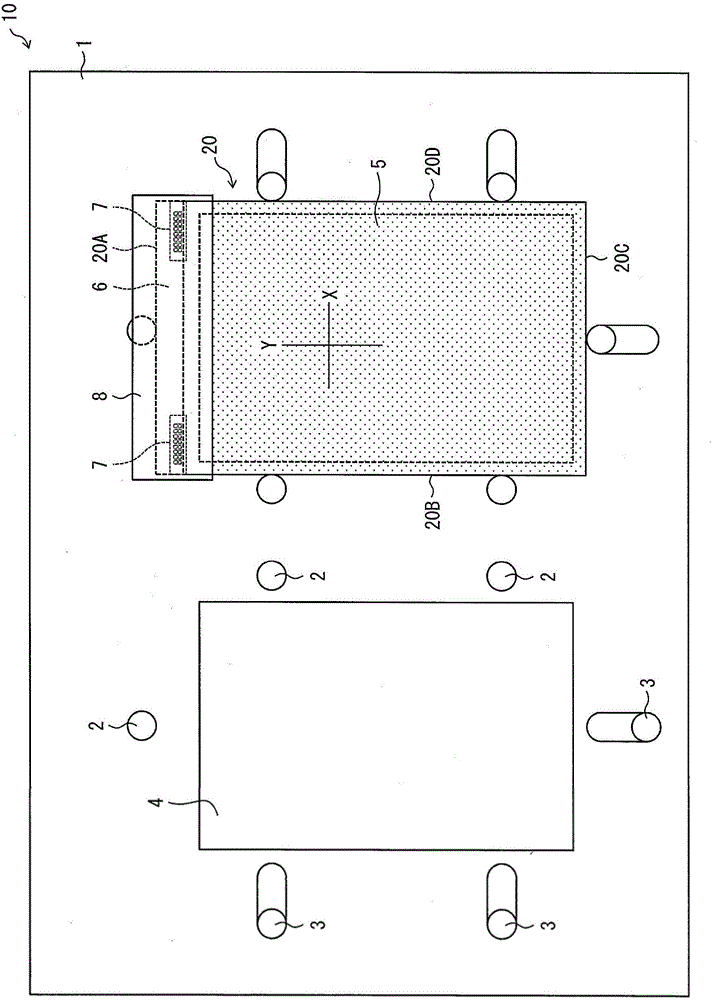

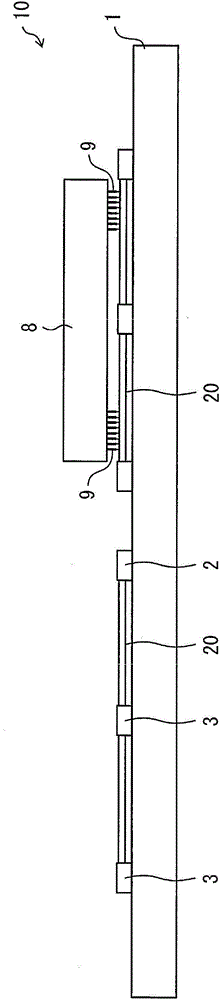

[0088] figure 1 It is a plan view showing a schemati...

Embodiment approach 2

[0128] based on Figure 8 to Figure 11 Another embodiment of the present invention will be described below. In addition, for convenience of description, members having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals, and descriptions thereof are omitted.

[0129] Figure 8 It is a plan view showing a schematic configuration of an inspection module 30 to be inspected by the lighting inspection device 10A of the present embodiment. Figure 9 It is a plan view showing the schematic configuration of 10A of lighting inspection apparatuses of this embodiment. Figure 10 It is a side view which shows the schematic structure of 10 A of lighting inspection apparatuses of this embodiment. Figure 11 It is an enlarged plan view showing the configuration of an FPC (flexible printed circuit board) 22 for external driving in the inspection module 30 .

[0130] Such as Figure 8 As shown, the inspection module 30 includ...

Embodiment approach 3

[0153] based on Figure 12 and Figure 13 Still another embodiment of the present invention will be described below. In addition, for convenience of description, members having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals, and descriptions thereof are omitted.

[0154] The lighting inspection device of the present embodiment is different from the first embodiment described above in that the detection portion is a detection FPC 32 including an FPC (flexible printed circuit board). Figure 12 The structure of the detection FPC 32 in the lighting inspection device of this embodiment is shown, Figure 12 (a) is a top view, Figure 12 (b) is a side view. in addition, Figure 13 It is a plan view schematically showing the state where the probe FPC 32 is in contact with the inspection terminal portion 7 in the lighting inspection device according to the present embodiment.

[0155] Such as Figure 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com