A non-polar arc extinguishing system for high voltage DC contactor

A high-voltage direct current and contactor technology, applied in the field of arc extinguishing system, can solve the problems of low on-load switching life, waste of installation space, and large device volume, etc., to improve on-load switching life, save installation space, and good arc extinguishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

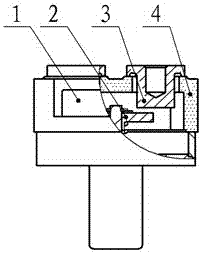

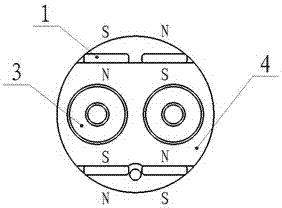

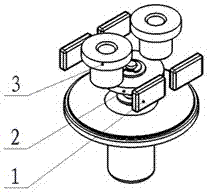

[0019] A high-voltage DC contactor non-polar arc extinguishing system, as attached Figure 1-3 As shown, a contact chamber 4 is included, the bottom of the contact chamber 4 is provided with a movable contact 2, and the top is provided with two static contacts 3, and two permanent magnets 1 are respectively arranged in parallel on both sides of the static contact 3. The polarities of the permanent magnets 1 on the same side of a static contact 3 are opposite; wherein the direction of the magnetic field lines between the permanent magnets 1 on both sides of the same static contact 3 is perpendicular to the moving direction of the movable contact 2, and the same static contact 3 The polarities of the permanent magnets 1 on both sides are the same.

[0020] The lower surface of the permanent magnet 1 is lower than the upper surface of the movable contact 2 when the contacts are disconnected, and the upper surface of the permanent magnet 1 is higher than the lower surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com