Direct current de-icing device based on full-bridge modular multilevel converter

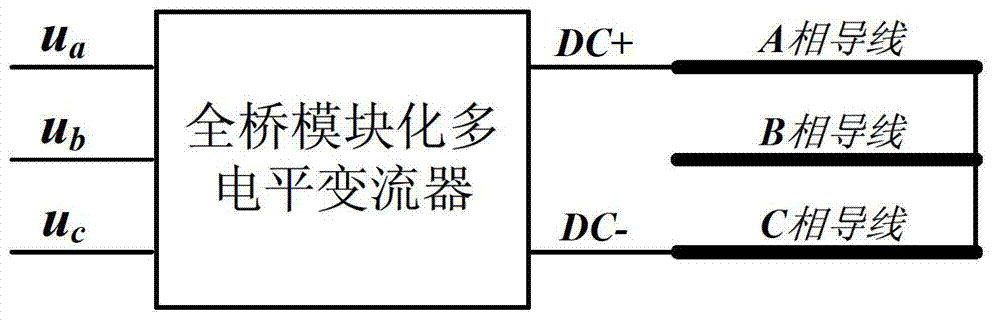

A modular multi-level, DC ice-melting technology, which is applied in the direction of circuit devices, cable installation, output power conversion devices, etc., can solve the problem of small adjustable range of DC voltage, discounted availability rate, inability to effectively adapt to transmission lines, etc. problem, to achieve the effect of small size, low loss and small harmonic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical principle and implementation of the DC deicing device based on the full-bridge modular multilevel converter designed by the present invention will be described in detail below in conjunction with the accompanying drawings.

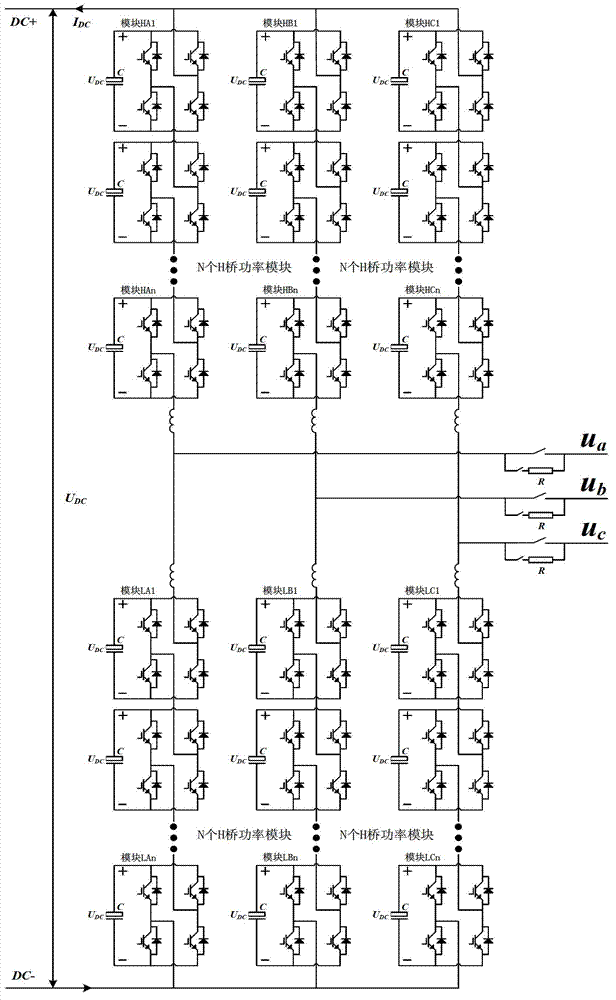

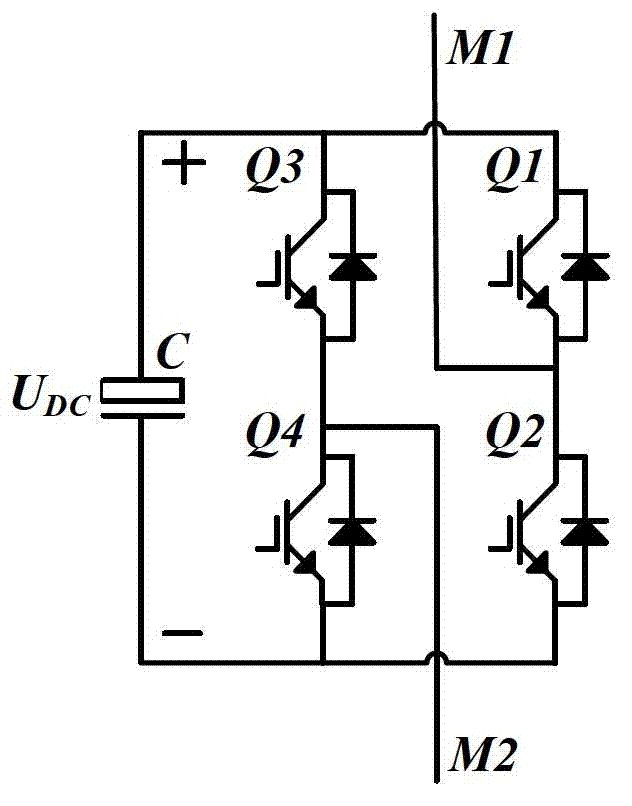

[0023] The DC ice-melting device topology of the full-bridge modular multi-level structure designed by the present invention is as attached figure 1 shown. The full-bridge modular multilevel converter is a three-phase bridge structure, each phase of the converter includes an upper bridge arm and a lower bridge arm, and the upper and lower bridge arms are respectively composed of N full-bridge power modules at the head and tail Composed in series to form a chained multi-level structure, and each bridge arm is the first, second, ..., Nth full-bridge power module from top to bottom, where N is an integer greater than 1; The first end of the first power module of the bridge arm is connected together to form the positive pole of the common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com