Substrate processing apparatus, nozzle and substrate processing method

A substrate processing device and substrate technology, which is applied to the surface coating device, electrical components, semiconductor/solid device manufacturing, etc., can solve the problems of disturbing the liquid surface, inability to supply new liquid uniformly, and processing substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0106]

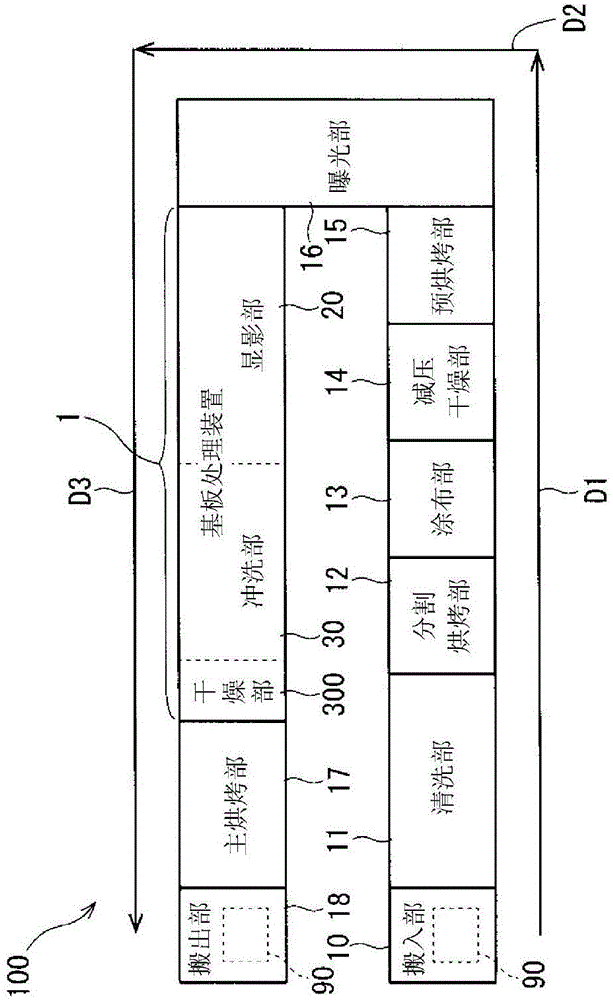

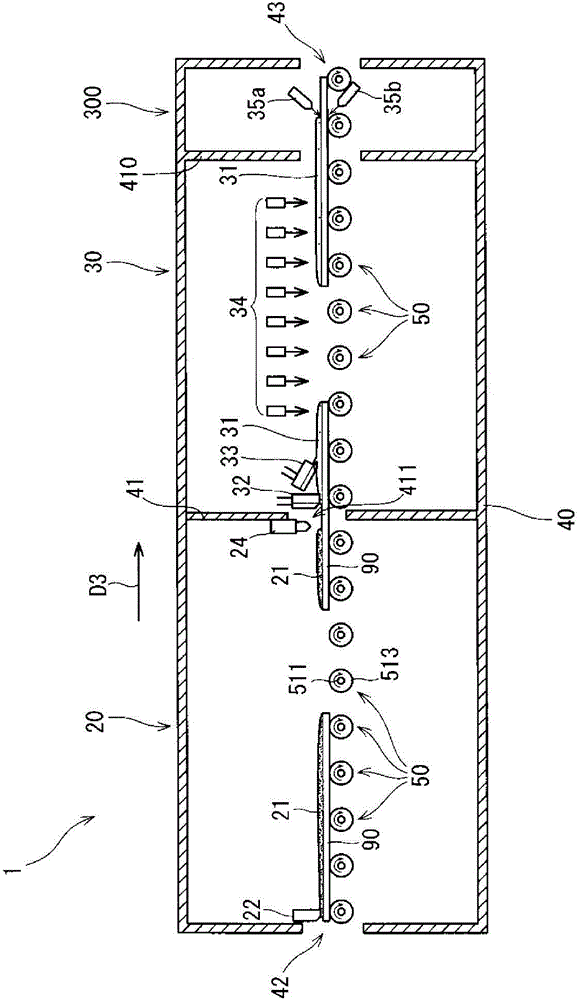

[0107] figure 1 It is a schematic plan view showing a substrate processing system 100 including the substrate processing apparatus 1 .

[0108] The substrate processing system 100 processes a square glass substrate (hereinafter simply referred to as a substrate) 90 for manufacturing a screen panel of a liquid crystal display device.

[0109] The substrate processing system 100 includes a loading unit 10 , a cleaning unit 11 , a divide bake unit 12 , a coating unit 13 , a reduced-pressure drying unit 14 , and a pre-bake unit 15 . The carrying-in unit 10 is a part that receives a substrate 90 to be processed in the substrate processing system 100 . The cleaning unit 11 cleans and cleans the substrate 90 carried in by the carrying-in unit 10 . The divided baking unit 12 dries the substrate 90 to which the cleaning liquid adhered in the cleaning unit 11 .

[0110] The coating unit 13 coats a processing liquid (here, a resist) on the surface of the substrate 90 dried ...

no. 2 Embodiment approach

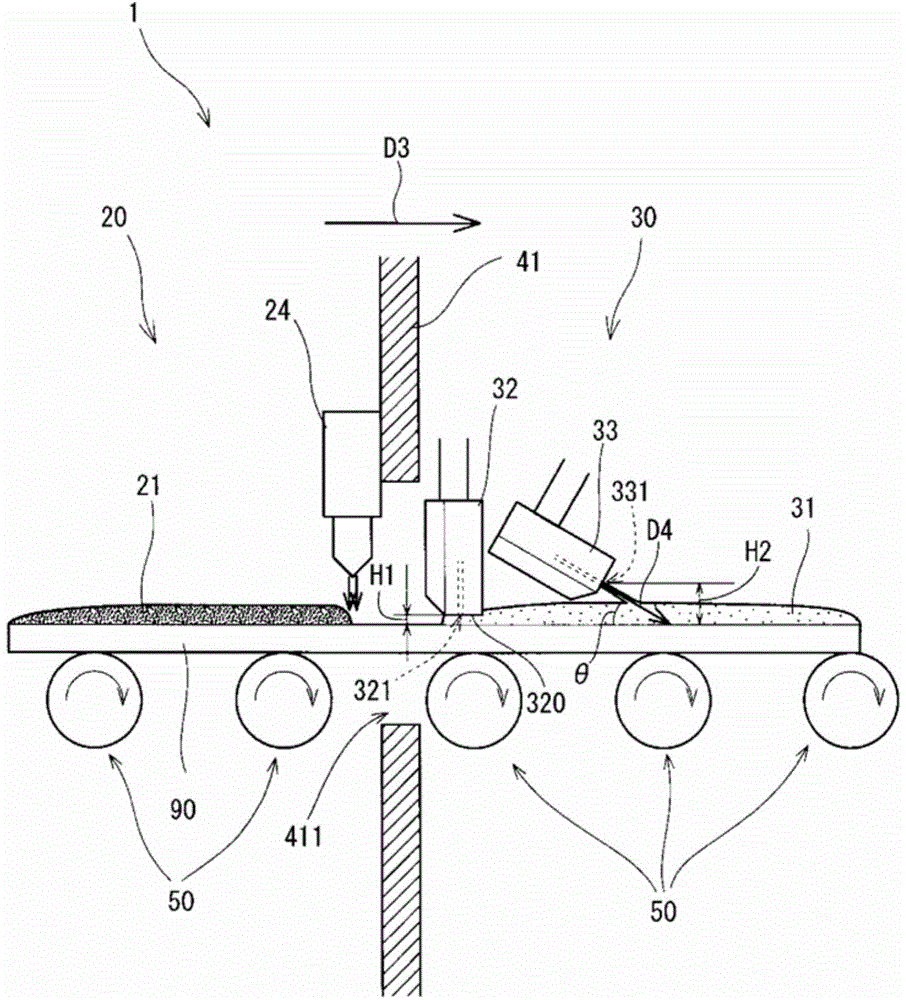

[0150] The substrate processing apparatus 1 of the above-described embodiment includes two nozzles (a rinse coating nozzle 32 and a liquid knife nozzle 33 ) in the rinse unit 30 . However, it is also conceivable to configure these two nozzles with one nozzle. In addition, in the following description, members having the same functions as those already described are assigned the same symbols or symbols with alphabets (alphabets) added thereto, and detailed explanations may be omitted.

[0151] Image 6 It is an enlarged schematic side view showing a boundary portion between the developing unit 20 and the rinse unit 30A in the substrate processing apparatus 1A according to the second embodiment. Such as Image 6 As shown, the substrate processing apparatus 1A is different from the substrate processing apparatus 1 in that a single nozzle 36 is provided instead of the rinse lamination nozzle 32 and the liquid knife nozzle 33 .

[0152] The nozzle 36 has a first discharge part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com