Grain cylinder automatic return control device and method for a high-position grain unloading combine harvester

A combined harvester and automatic return technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of not being able to meet the production needs, the low precision of the unloading mechanism, and the inability to be in place at one time, so as to improve the operation efficiency , Shorten the return time, reduce the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

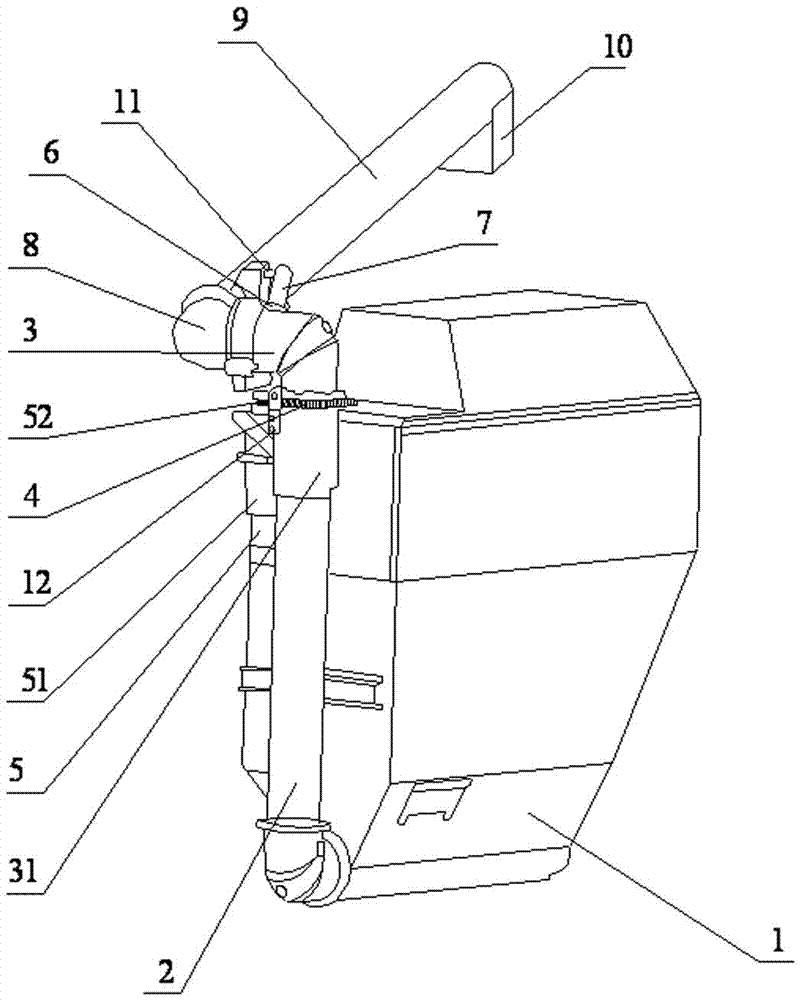

[0041] Embodiment 1, the automatic return control device of the grain cylinder of the high-position grain unloading combine harvester, refer to the attached figure 1 .

[0042] The control device of the present invention includes a grain unloading mechanism, a control mechanism and a driving mechanism. The grain unloading mechanism comprises a grain box 1, a horizontal grain cylinder 9, a vertical grain cylinder 2 and a grain discharge port 10, the grain discharge port 10 is installed on the outer end of the horizontal grain cylinder 9, the grain discharge port 10 is vertically downward, and the vertical grain cylinder 2 is fixedly installed on the grain tank 1, and the horizontal grain cylinder 9 is rotatably connected to the vertical grain cylinder 2.

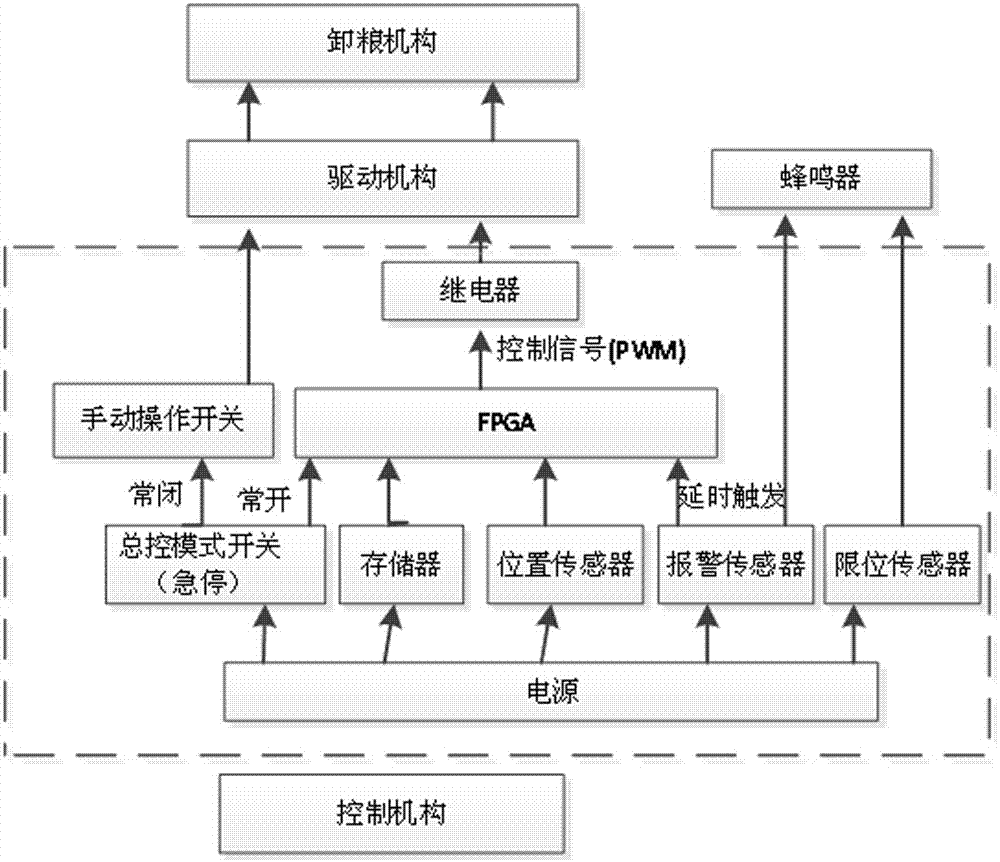

[0043] The control mechanism includes controller, memory, position sensor, alarm sensor, relay, master control switch, handle switch and power supply. The controller uses logic gate circuit (programmable gate array FPGA) as ...

Embodiment 2

[0046] Embodiment 2, the automatic return control device of the grain barrel of the high-position grain unloading combine harvester, refer to the attached Figure 2-7 .

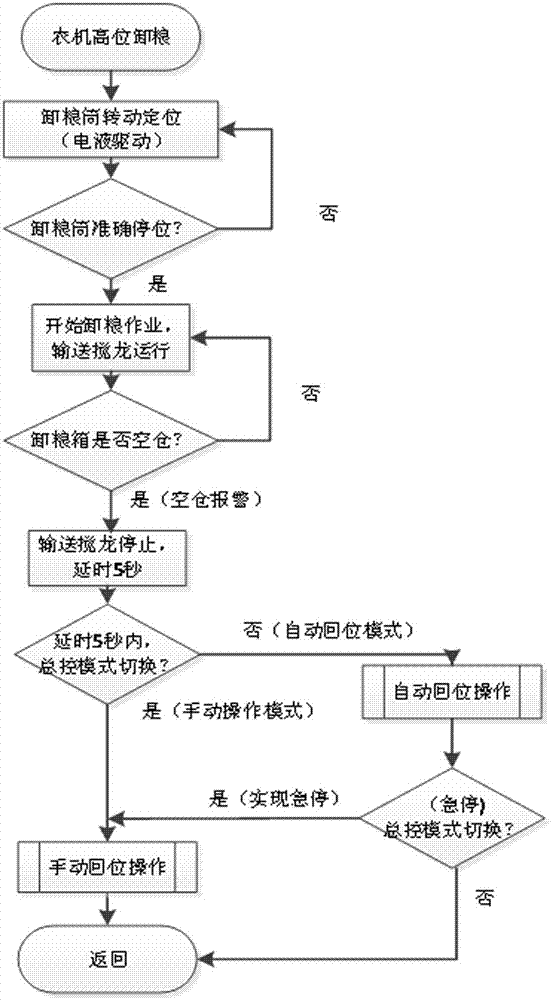

[0047] A method for automatic return control of a grain cylinder of a high-position unloading combine harvester, the method applies the automatic return control device of Embodiment 1, and includes the following steps:

[0048] 1) Manually operate the handle switch, and control the horizontal grain cylinder to rotate upwards through the driving mechanism until the grain unloading port leaves the fixed bracket;

[0049] 2) Manually operate the handle switch, and control the horizontal grain cylinder to rotate to the right through the driving mechanism until the grain unloading port reaches the designated position;

[0050] 3) When the grain unloading port reaches the designated position, the position sensor is triggered, the control mechanism starts the grain unloading mechanism through the master control switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com