A disc-shaped valve tray

A float valve tray, disc-shaped technology, which is applied in the field of general physical separation operation devices, can solve the problems of unsatisfactory air flow treatment by the float valve, insufficient gas-liquid contact, irregular air flow rising, etc., so as to reduce fog and foam. The amount of entrainment, the air distribution is fine and uniform, and the effect of promoting continuous renewal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

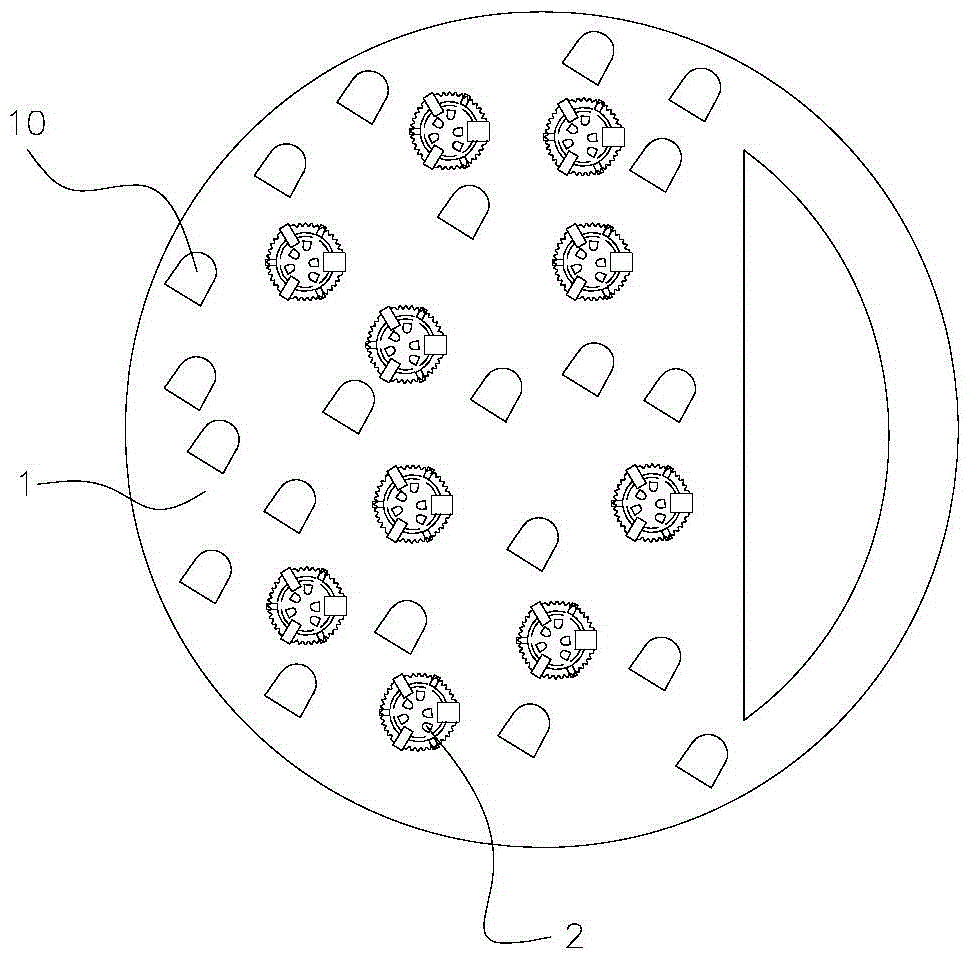

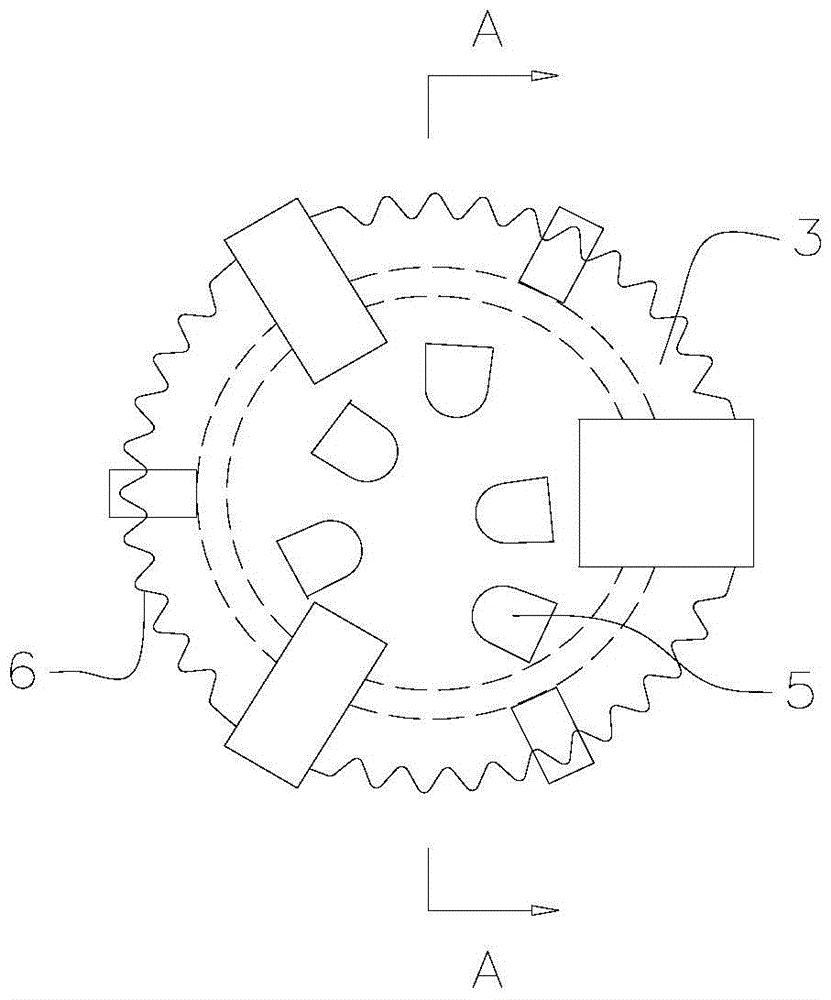

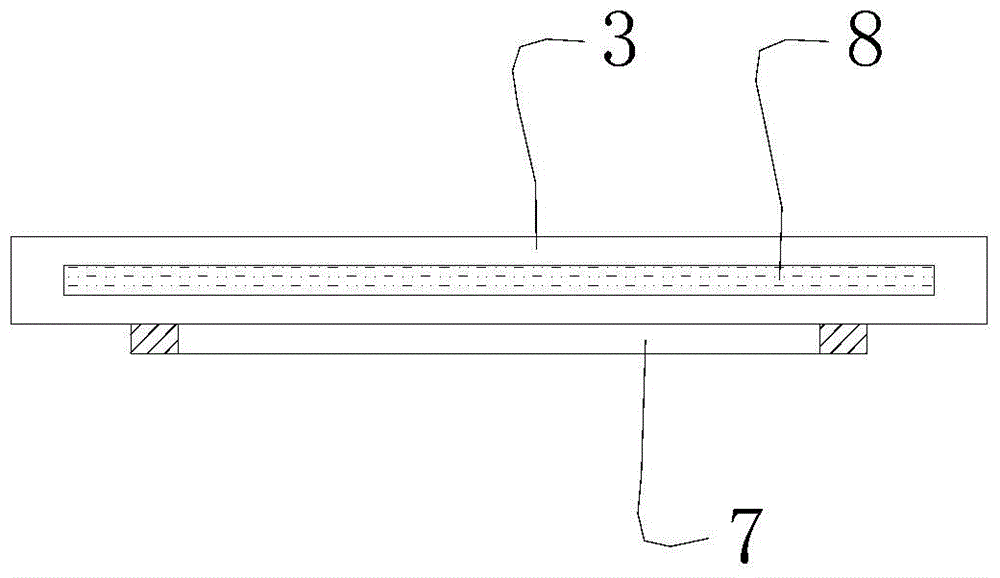

[0018] The disk-shaped valve tray of the present embodiment, such as Figure 1 to Figure 5 As shown, it includes a tray 1 and a float valve 2 that can move up and down. The tray 1 is formed with an installation hole for the installation of the float valve. The float valve 2 includes a circular valve cover 3 arranged above the tray 1 and a valve leg 4 extending downward from the periphery of the valve cover to the bottom of the tray. The valve legs 4 are distributed at intervals along the periphery of the valve cover 3 .

[0019] In this embodiment, the valve cover 3 is provided with at least two upwardly arched first tongue holes 5, preferably ranging from 2 to 5. The peripheral edge of the valve cover 3 is provided with a sawtooth edge 6 folded downward, and the sawtooth edge 6 of the valve cover is used to abut against the upper surface of the tray 1 when the float valve 2 falls. A number of second tongue holes 10 are opened on the tray 1, and the second tongue holes 10 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com