Anti-spin spinning method

A spinning equipment and spinning wheel technology, applied in the field of reverse spinning, can solve the problem of difficult spinning of ultra-long thin-walled cylindrical parts, and achieve the effects of small processing volume, improved use accuracy and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

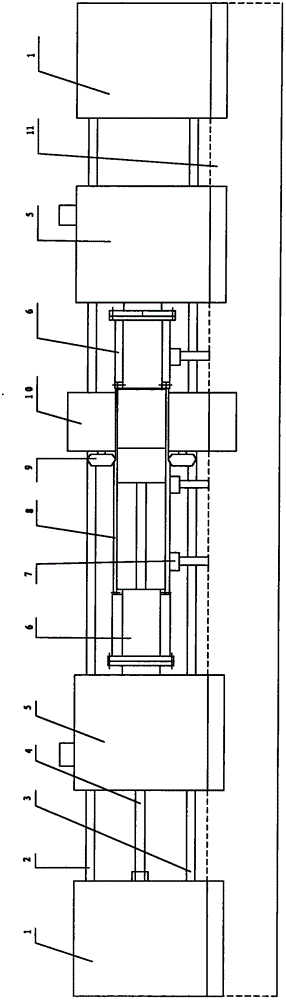

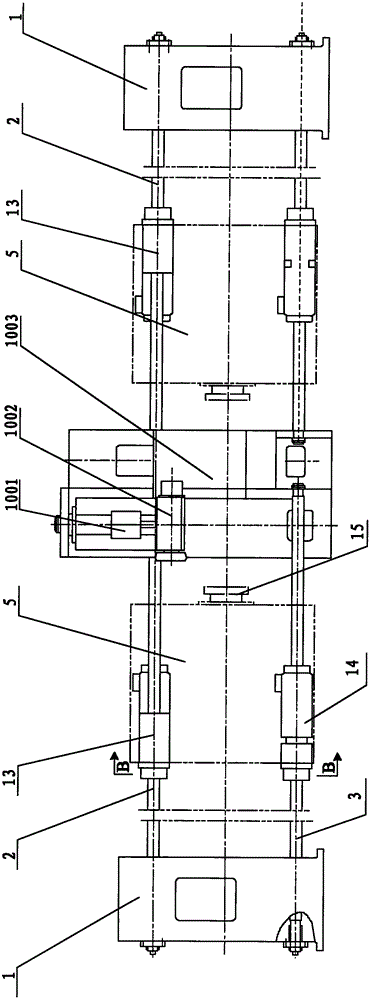

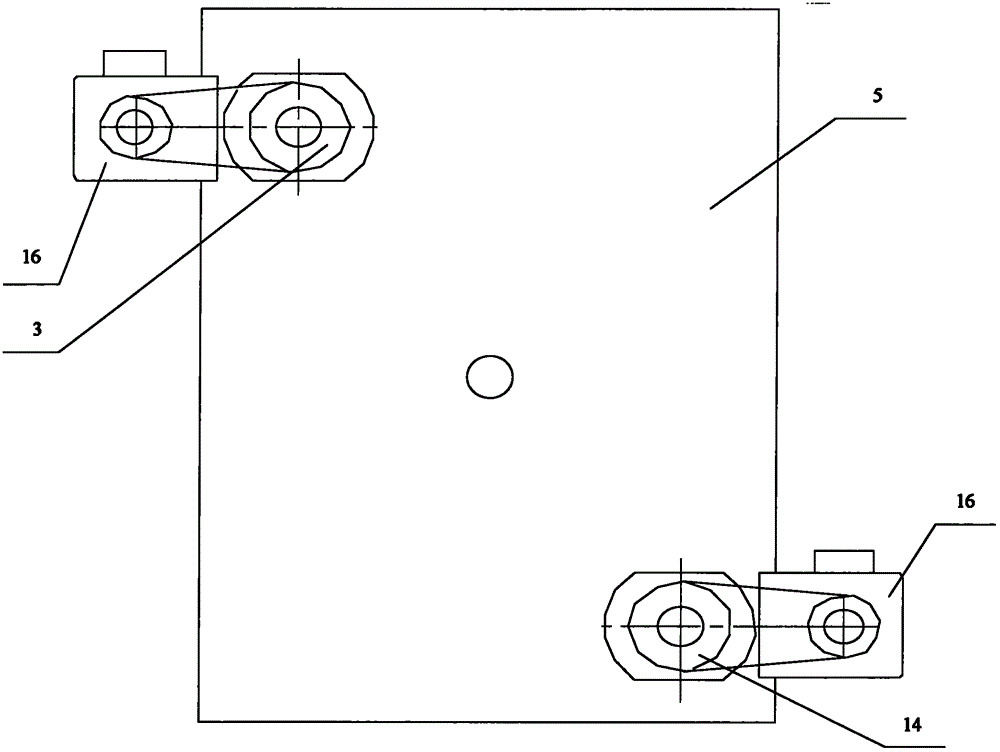

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0055] Processing ultra-long thin-walled cylindrical parts, the wall thickness is 5mm, the manufacturing length L is 8000mm, the product outer diameter φD is 504mm, and the material is 0Cr18Ni9 stainless steel alloy.

[0056] The preparation process is as Figure 6 shown in the following steps:

[0057] 1. Prepare spinning blank

[0058] (1) Rough design

[0059] Design the spinning blank as Figure 7 , 8 The straight cylindrical structure shown has a wall thickness t 1 Calculate the wall thickness t of the spinning blank according to the spinning force of the spinning equipment, the wall thickness requirements of the spinning product, the limit thinning rate of the spinning material, the design of the spinning pass, etc. 1 , blank length L 1 According to the calculation method of equal volume and considering the reserved process allowanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com