A tubular multilayer multiaxial warp knitting machine

A multi-axial, warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as easy loose knitting structure, affect production efficiency, limit weaving level, etc., achieve a wide range of varieties and improve Cloth surface quality, effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

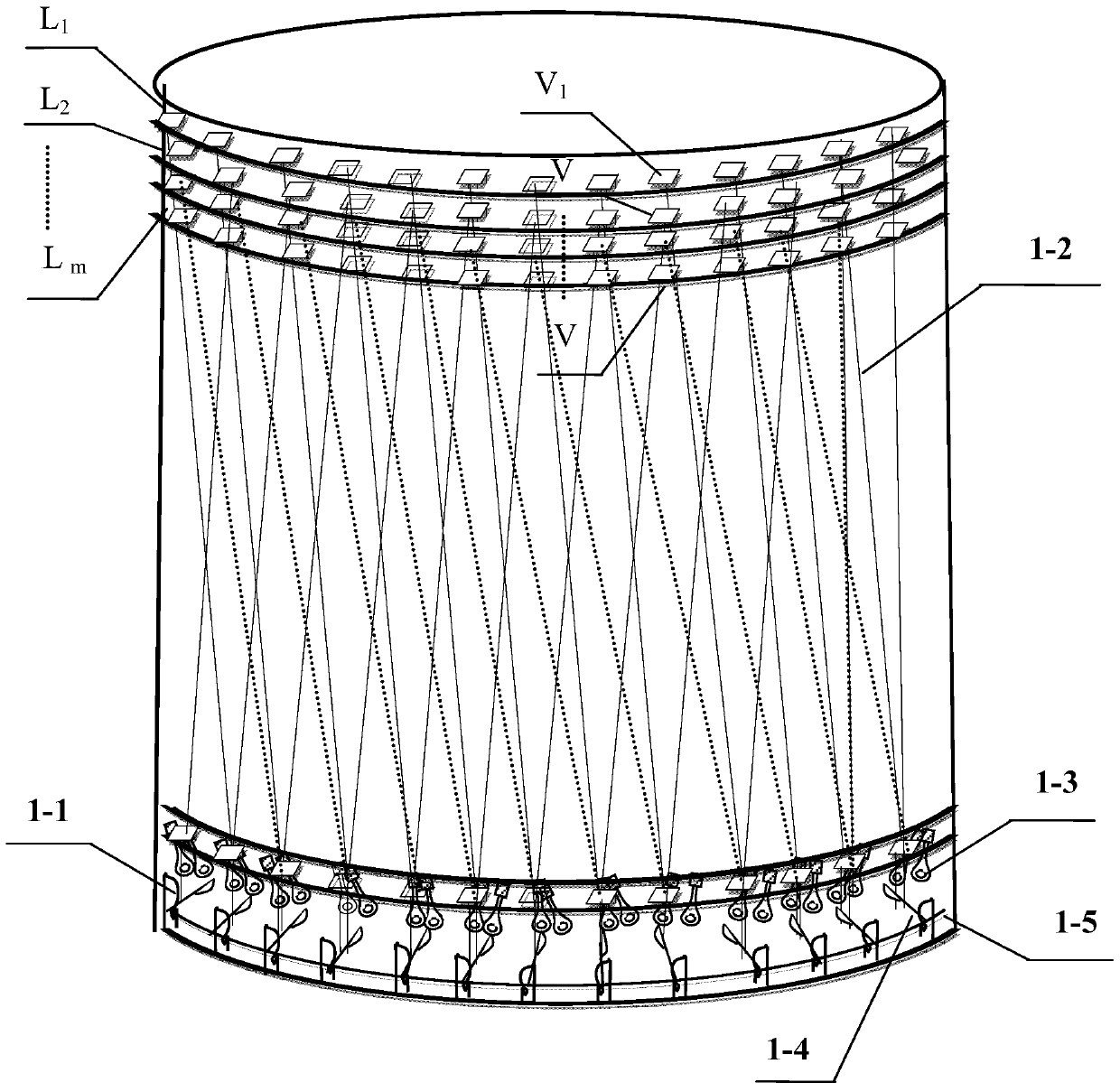

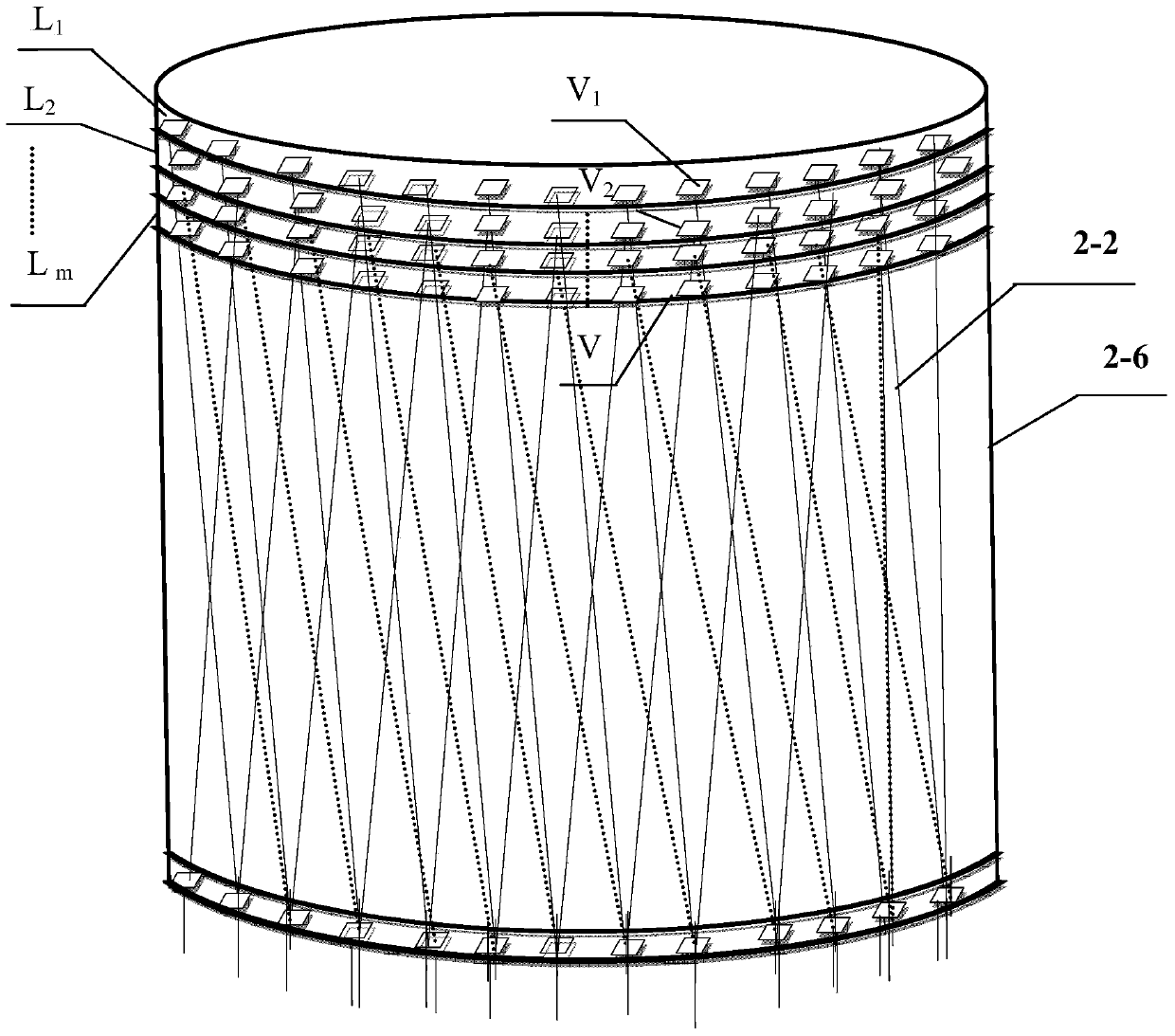

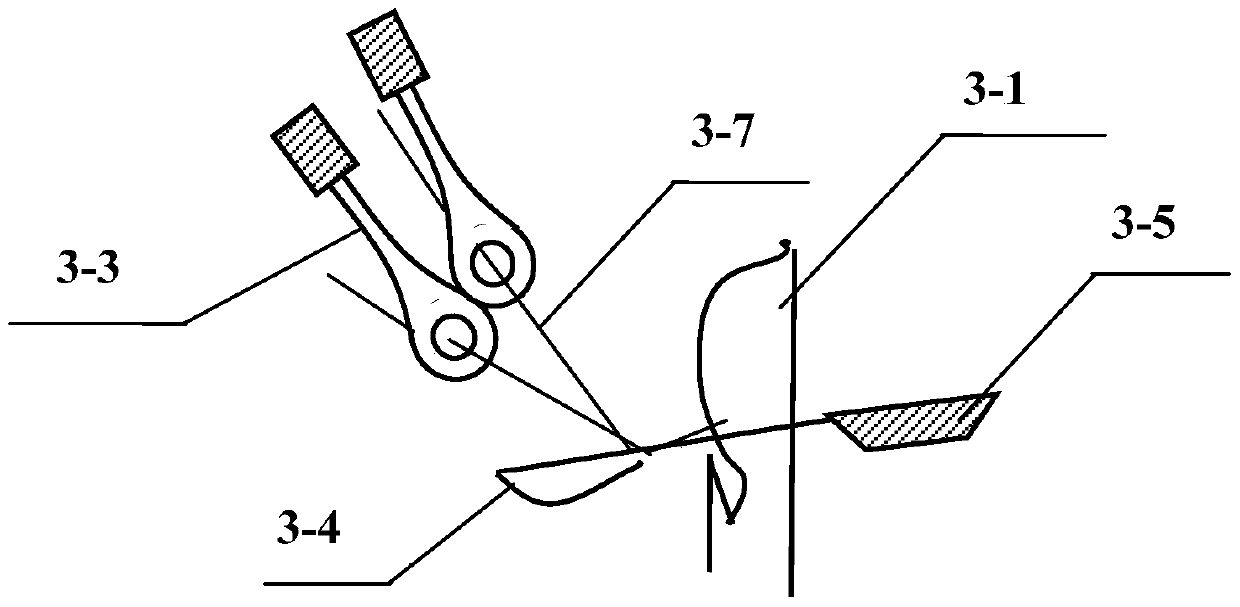

[0019] see figure 1 A kind of tubular multilayer multiaxial warp knitting machine shown, said warp knitting machine comprises figure 2 The weft laying mechanism shown and image 3 The loop forming mechanism shown. The weft laying mechanism includes a yarn carrier V 1 , V 2 ...V m and interlining yarns (1-2, 2-2). The knitting mechanism includes guide needles (1-3, 3-3), crochet needles (1-4, 3-4, 4-4), circular needle beds (1-5, 3-5), sinkers ( 1-1, 3-1) and binding yarn (3-7).

[0020] see figure 2 The weft-laying mechanism of the tubular multi-layer multi-axial warp knitting machine shown has a transmission system that can introduce yarn into the weaving mechanism. The yarn carrier V 1 , V 2 ...V m set to L 1 , L 2 ...... L m The layers can be rotated relative to each other and the yarn can be inserted from different directions, and the yarn holding capacity is large. The inserting yarns (1-2, 2-2) are stretched parallel to the yarn carrier V 1 , V 2 ...V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com