Anti-circumvention enclosure device and construction method for underground diaphragm wall joints

An underground diaphragm wall and construction method technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of manpower, material resources, seam seepage, time-consuming and other problems, saving time, increasing sealing, Ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

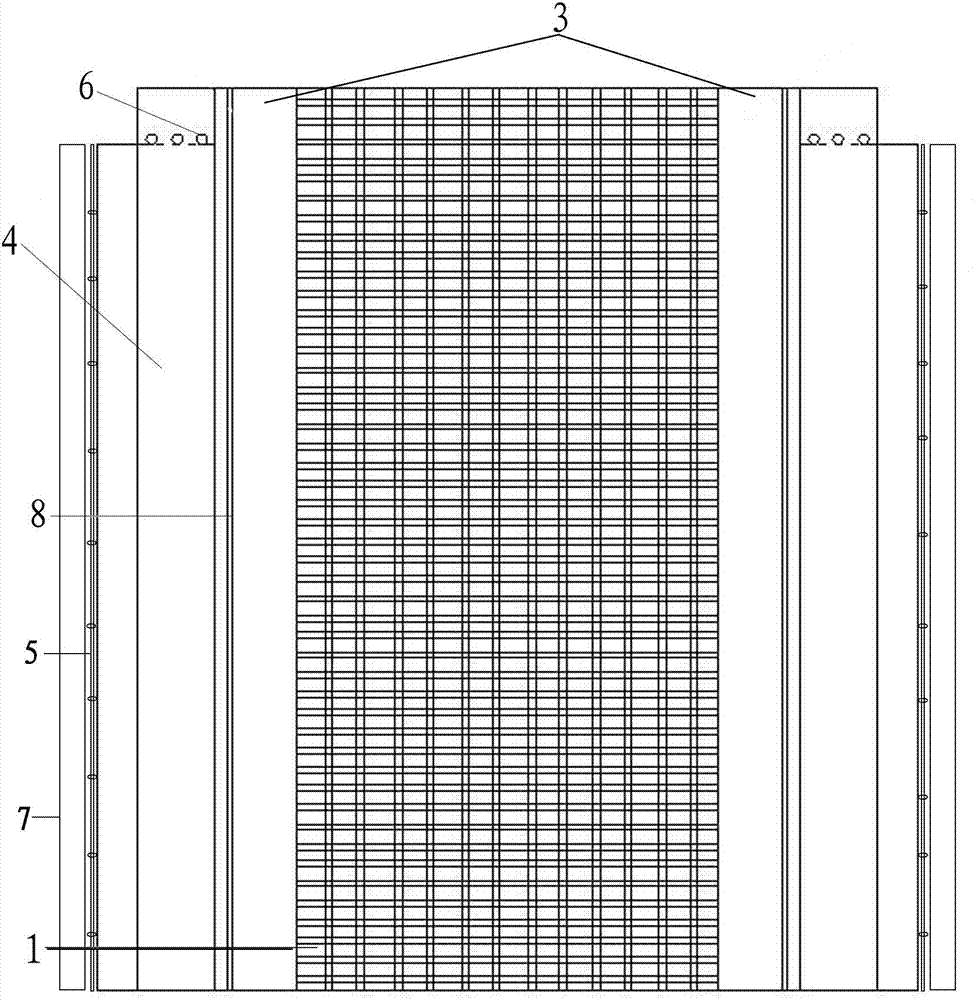

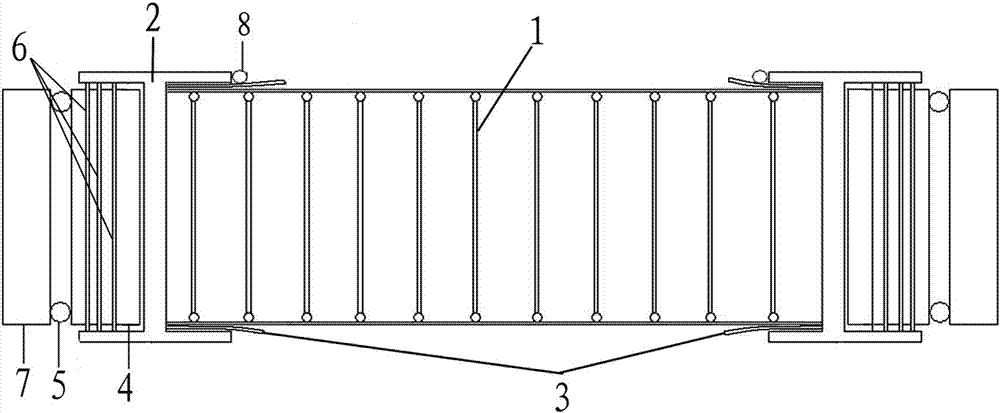

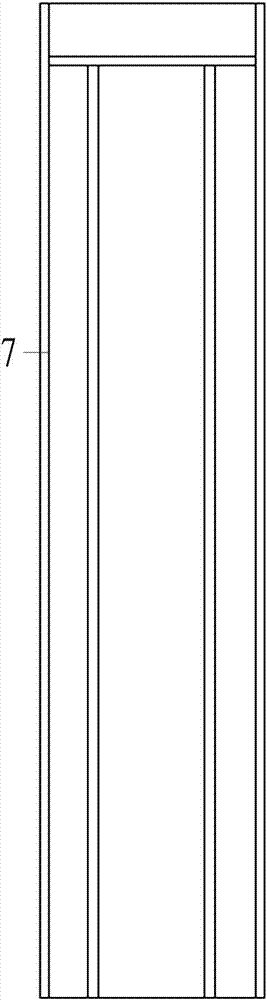

[0022] An underground diaphragm wall joint anti-flow containment device, which is set based on the underground diaphragm wall steel cage 1 and the joint I-beam 2, including the upper part of the inner side of the bottom flange of the joint I-beam 2 and the lower part of the inner side of the top flange The galvanized steel plate 3 welded through the length, the sealing plate 4 bound on the back side of the web of the joint I-beam 2, and the joint box 7 set on the top of the sealing plate 4 and fixed on the guide wall; the galvanized steel plate 3 is placed down During the process, it opens in a trumpet shape, and the outer side of the sealing plate 4 is fixed with two rows of fixing rods 5;

[0023] Along the side edges of the top flange of the joint I-beam 2 and the upper part of the galvanized steel sheet 3, a fixing steel bar 8 for fixing the galvanized steel sheet is smoothly arranged. The sealing plate 4 is a foam board wrapped and sealed with plastic cloth on the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com