Embedded sealing and isolating sealed casing head

A sealing casing and embedded technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of wasting energy such as water resources, wasting energy, environmental pollution, etc., and achieves the convenience of replacing parts , to ensure the overall sealing performance, the effect of light and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be further described below in conjunction with the drawings.

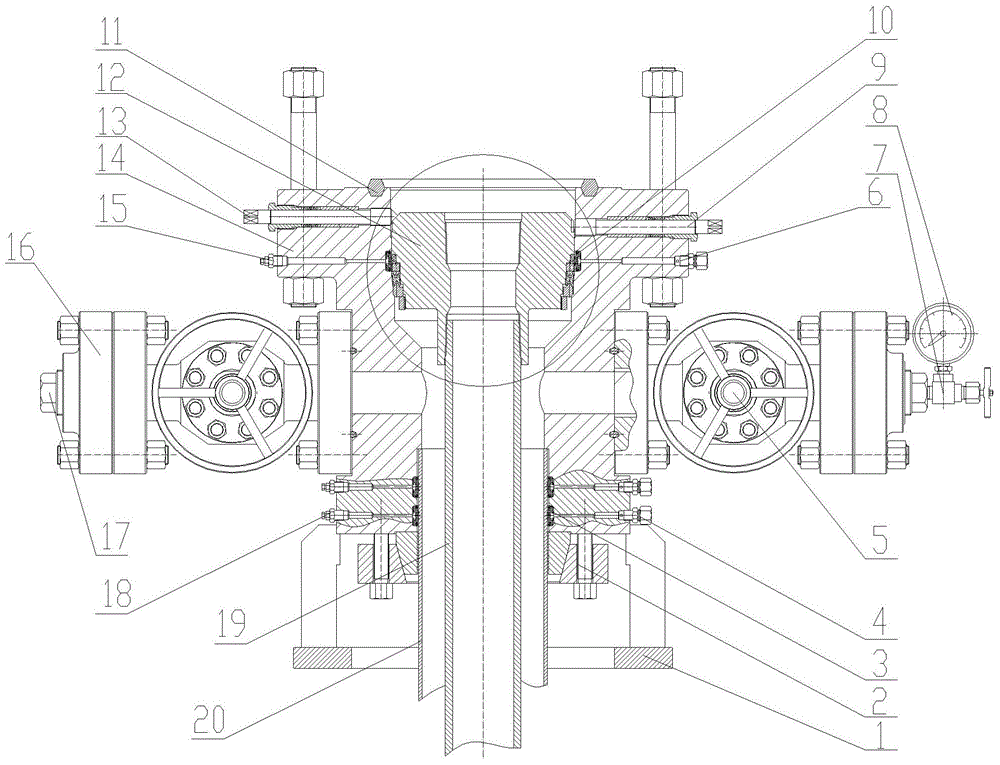

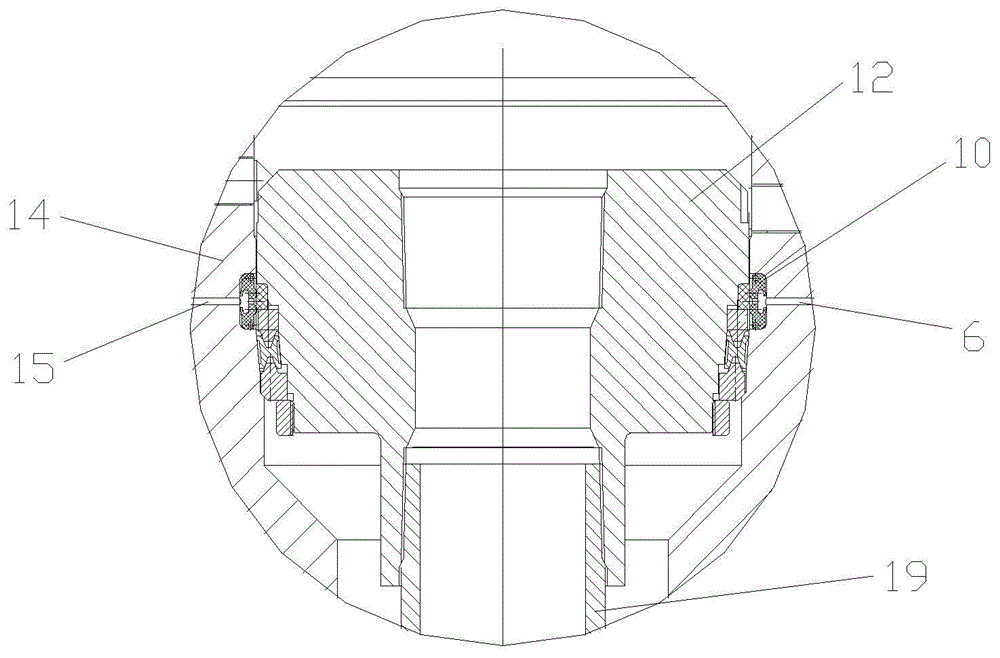

[0016] See attached figure 1 And attached figure 2 As shown, an embedded packing seal casing head includes a base assembly 1, a slip hanger 2, two rubber sealing rings 3, two grease injection valves 4, two flat gate valves 5, and a pressure gauge stop valve assembly 7. Pressure gauge 8, metal seal hanger 12, casing head body 14, two threaded flanges 16, plug connector 17, two relief plugs 18, oil layer casing 19 and technical casing 20; The technical casing 20 is coaxially suspended on the bottom of the casing head body 14 by the slip hanger 2, and the two rubber sealing rings 3 are coaxially sleeved on the technical casing On the outside of 20, the two grease injection valves 4 are respectively arranged on one side of the technical sleeve 20 and are correspondingly connected with the two rubber sealing rings 3, and the two relief plugs 18 They are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com