Powder metallurgy brake shoe structure and machining method thereof

A technology of powder metallurgy and brake shoes, which is applied in the field of powder metallurgy brake shoe structure and its processing, can solve problems such as weld cracks and shedding, achieve the effects of eliminating deformation, simplifying the manufacturing process, and eliminating hidden dangers of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

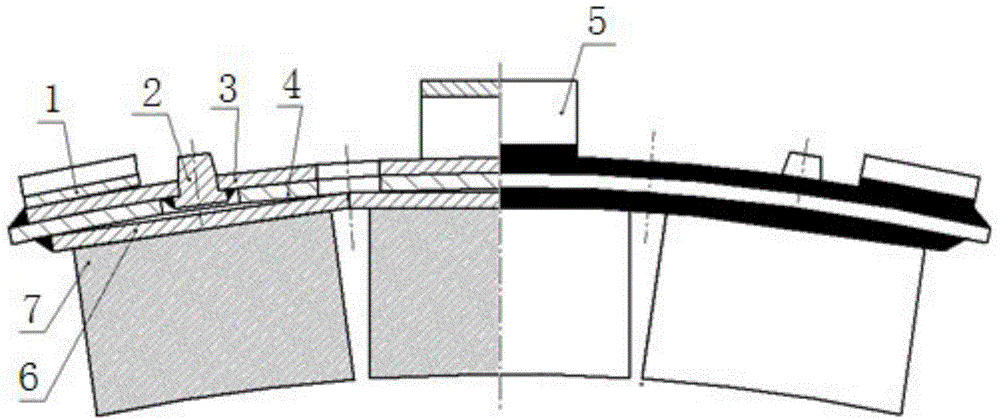

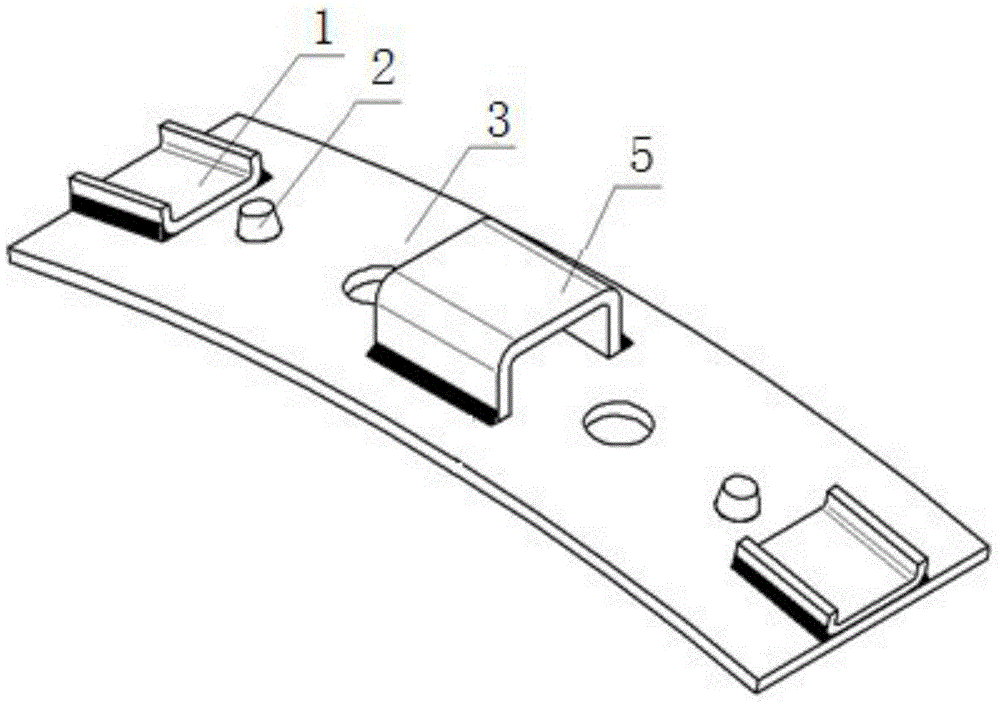

[0057] like Figure 3 to Figure 6As shown, a powder metallurgy brake shoe structure includes a back plate 4, a steel back 6, a friction body 7 and a tile back part 8, the back plate 4 is fixed on the inner arc of the tile back part 8, and the steel back 6 Located on the inner arc of the back plate 4, the friction body 7 is fixed on the steel back 6, and the tile back part 8 is composed of a tile back body 81 and an arc stopper 82 and a boss respectively arranged on the tile back body 81. The positioning pin 83 and the curved surface brake shoe nose 84 are formed, and the arc stopper 81, the boss positioning pin 83 and the curved surface brake shoe nose 84 are integrated with the tile back body 81. That is, the forming process is used to integrate the arc stopper 82, the boss positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com