Rotary extrusion type magnetorheological damper

A magnetorheological shock absorber and extrusion technology, applied in the field of magnetorheological shock absorbers and rotary extrusion magnetorheological shock absorbers, can solve the problem of large amount of magnetorheological fluid and fixed adjustment range of damping force. , large damping force and other problems, to achieve the effect of not easy to precipitate and block, small structure and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

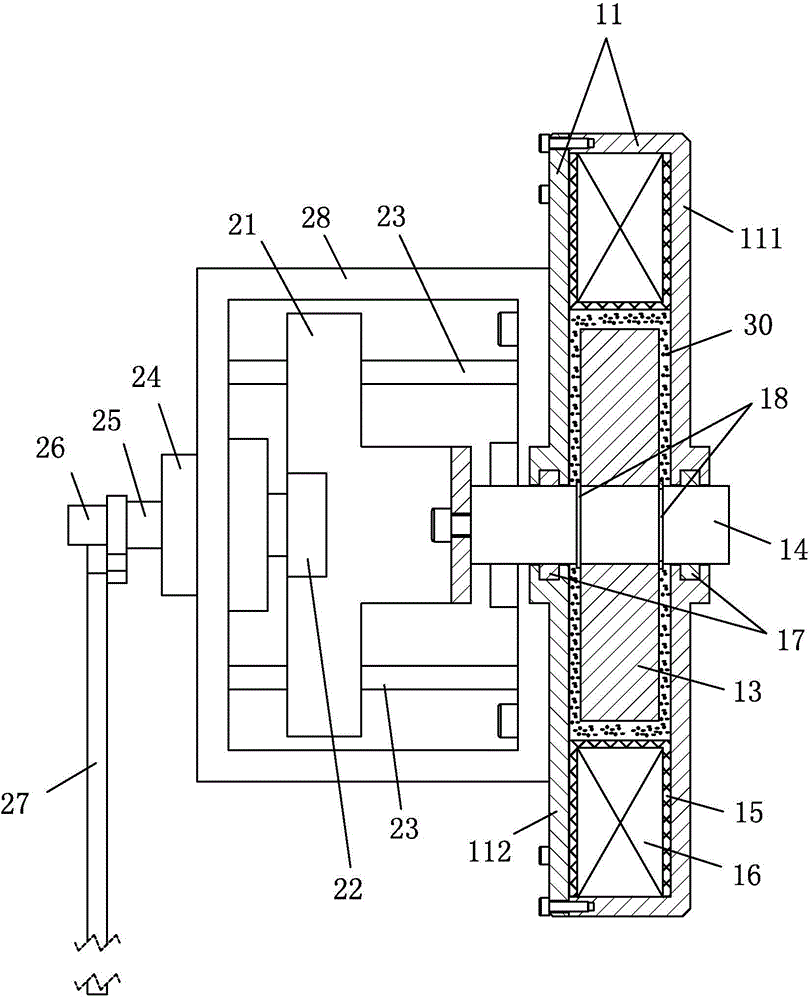

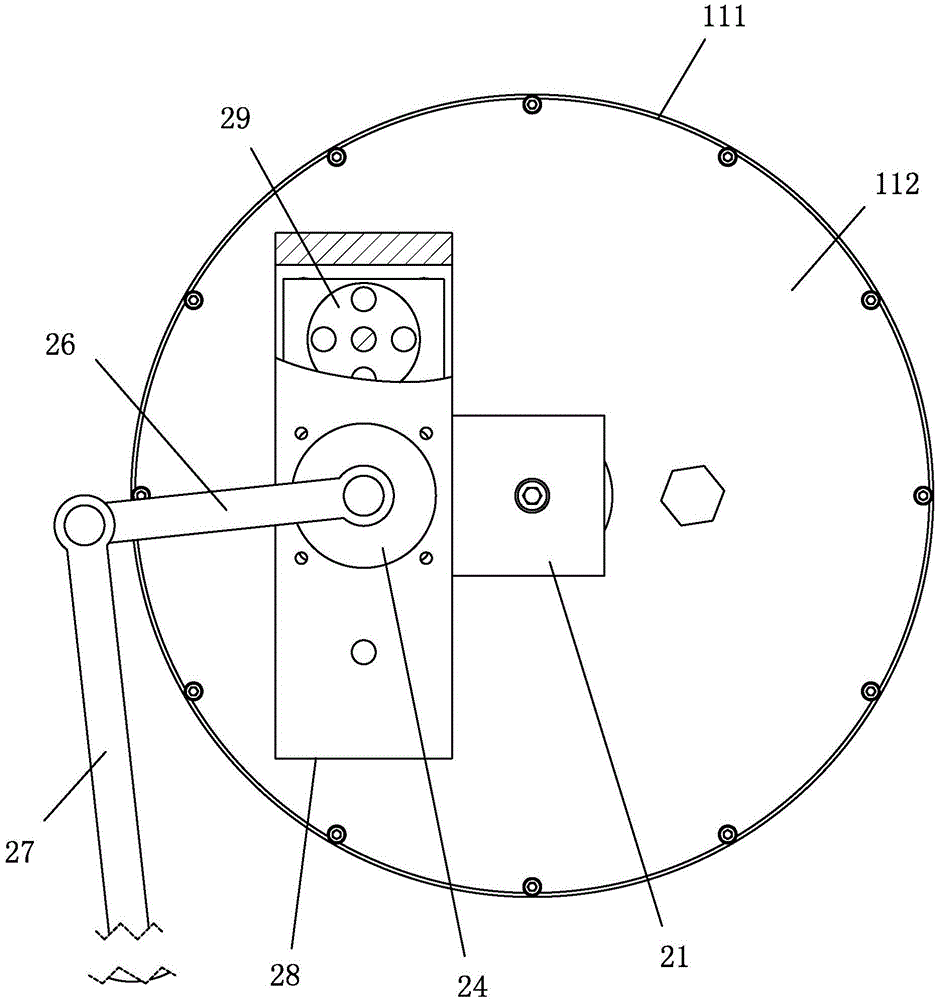

[0018] like figure 1 and figure 2 As shown, the rotary extrusion magneto-rheological shock absorber of the present invention comprises a shock absorber main body, and in the shock absorber main body, the extending end of the main shaft 14 that drives the disk 13 to perform a linear extrusion movement along the axis (that is, the main shaft 14 extends upward One end of the shell 11 of the shock absorber main body) is connected with the displacement transformation member, the displacement transformation member is assembled outside the shock absorber main body, and the displacement transformation member includes a bracket 28 fixed on the shock absorber main body, and the bracket 28 can be rectangular, The support seat 24 is fixed on the support seat 28, and one end of the lead screw 25 pierced in the support seat 24 is movably connected with the ball nut 22 installed on the moving block 21, and the moving block 21 is fixedly connected with the extending end of the main shaft 14....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com