Method and apparatus for determining titration end point and realizing automatic titration analysis by means of vision sensor

A visual sensor and titration endpoint technology, applied in the field of chemical analysis, to achieve the effects of improving detection efficiency, enriching original record information, and reducing the need for sample preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

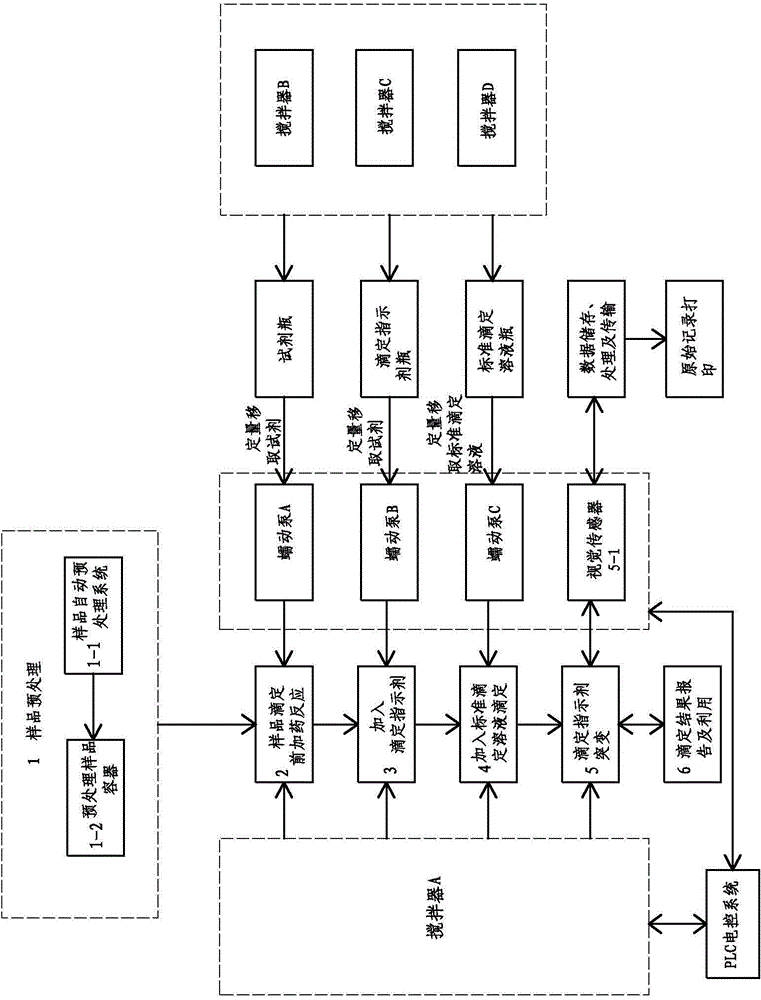

[0027] refer to figure 1 , 2 , the method for determining the titration end point by visual sensor to realize titration analysis automation of the present invention comprises the following steps: 1) sample pretreatment 1, realizing sample pretreatment 1 by sample automatic pretreatment system 1-1, sample automatic pretreatment system 1- 1 is the equipment that has been used maturely for a long time and is generally available for purchase. Different equipment configurations are obtained for different detection substances (or indicators). After being pretreated by the automatic sample pretreatment system 1-1, the sample needs to be filled in the pretreatment sample container 1-2. The specification of the pretreatment sample container 1-2 is determined according to the principle and standard of the titration analysis of the substance (o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap