Glass surface authentic and false defect identification method and system based on OCT complex signal

A glass surface, defect recognition technology, applied in character and pattern recognition, optical test flaws/defects, instruments, etc., can solve problems such as dust that cannot be excluded, and achieve the effect of accurate delineation, accurate identification, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, "true defects" refer to defects that cause deformation on the glass surface, such as air bubbles, distortions, bruises, tin spots, stones, etc.; "pseudo-defects" refer to defects that do not cause deformation on the glass surface, such as dust. "Standard single reflective interface" refers to an ideal smooth glass interface with no "true defects" or "false defects" on it. "Depth direction" refers to the thickness direction of glass. "Lateral" refers to a direction perpendicular to the depth direction.

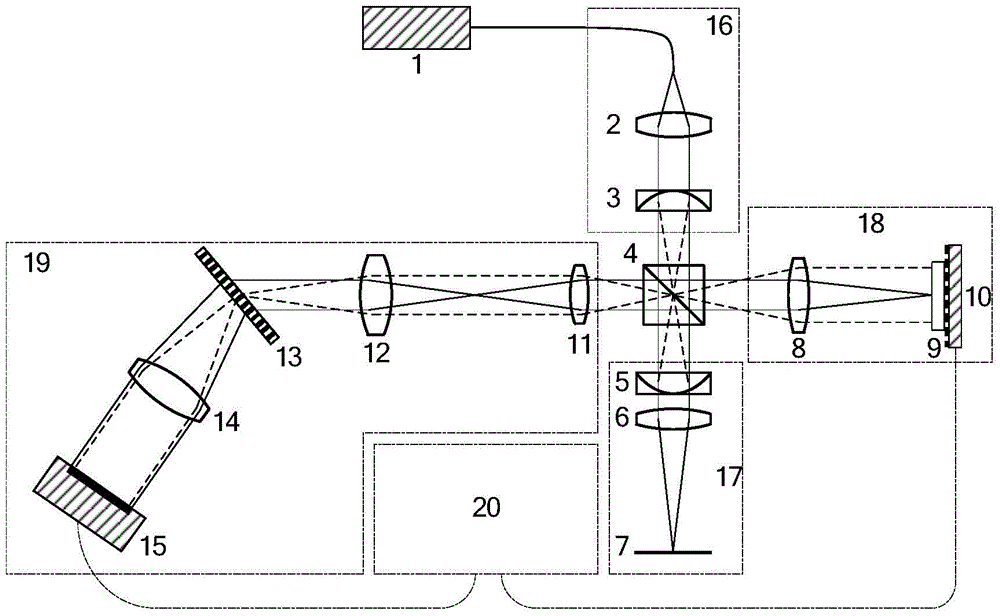

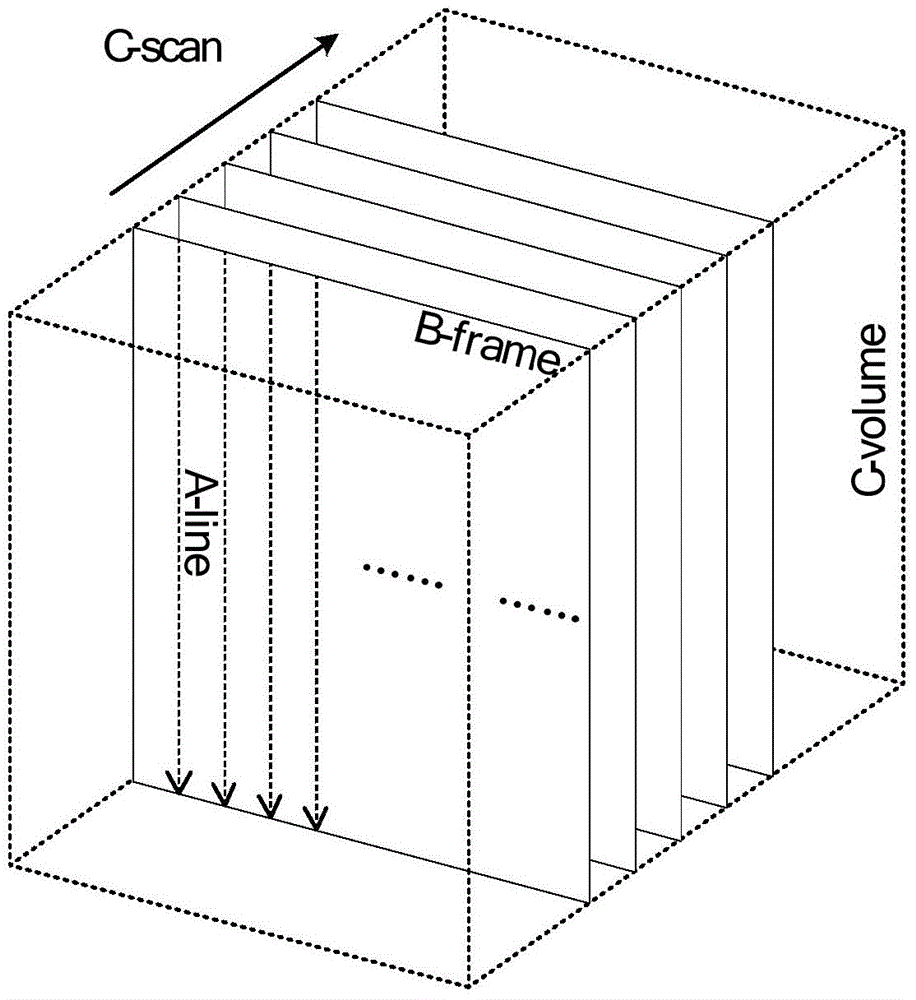

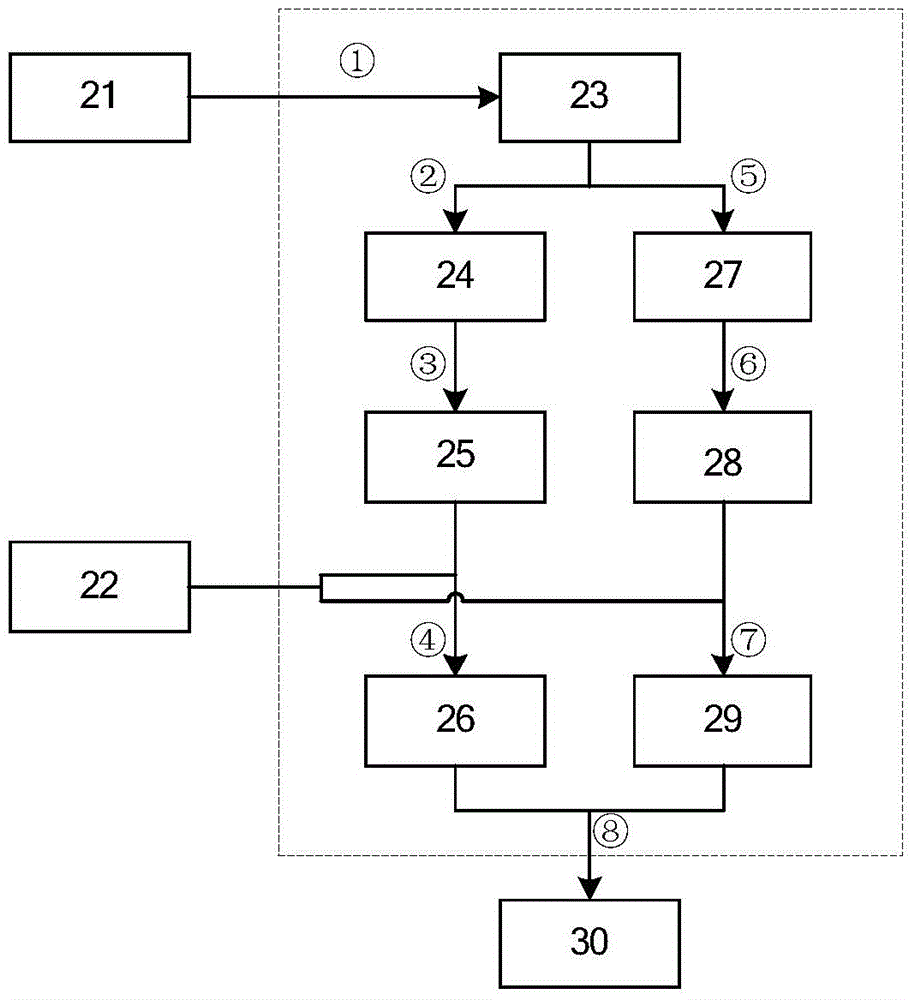

[0034] The object of the present invention is to provide a method and system for identifying authenticity defects on glass surfaces based on OCT complex analysis signals. In the present invention, the complex analysis signal obtained by OCT imaging is used to analyze the difference between the complex analysis signal along the depth direction at the glass interface and the complex analysis signal generated by the standard single reflection interface, and to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com