Apparatus for evaluating foam oil generation validity, and method thereof

A foam oil, effectiveness technology, applied in the direction of material inspection products, etc., can solve the problems of high price, time-consuming, inability to study the influence of foam oil stability, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and example the present invention will be further described:

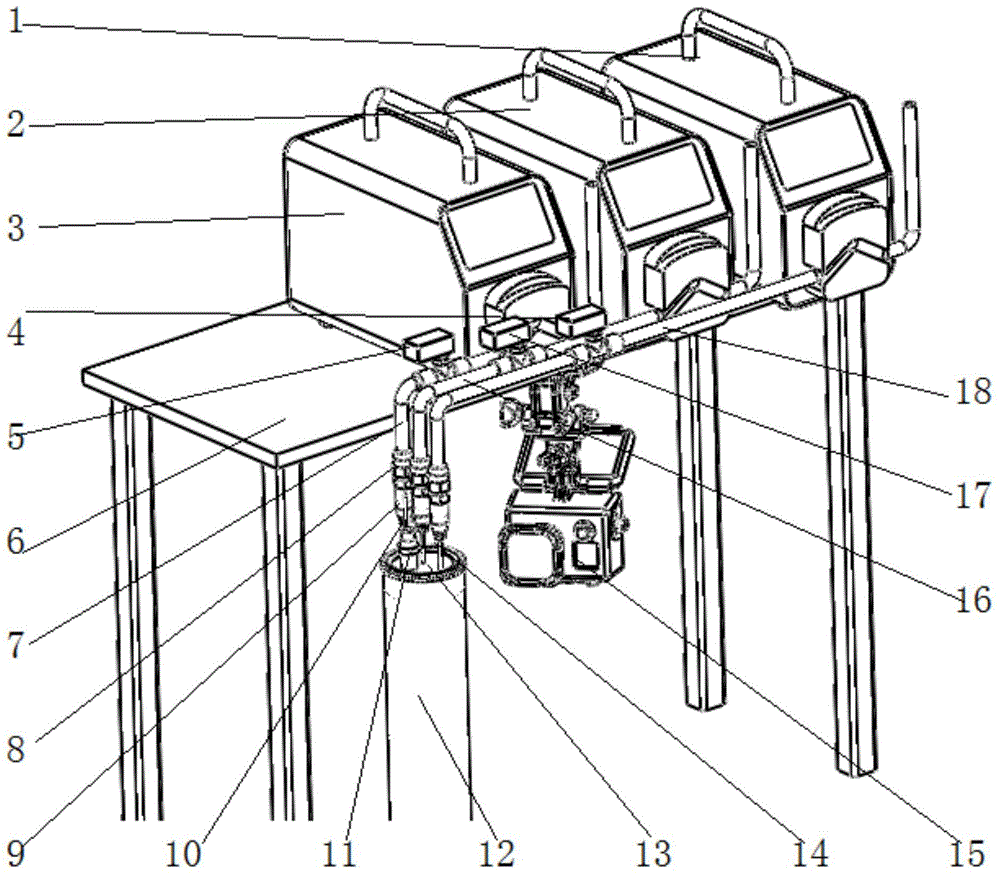

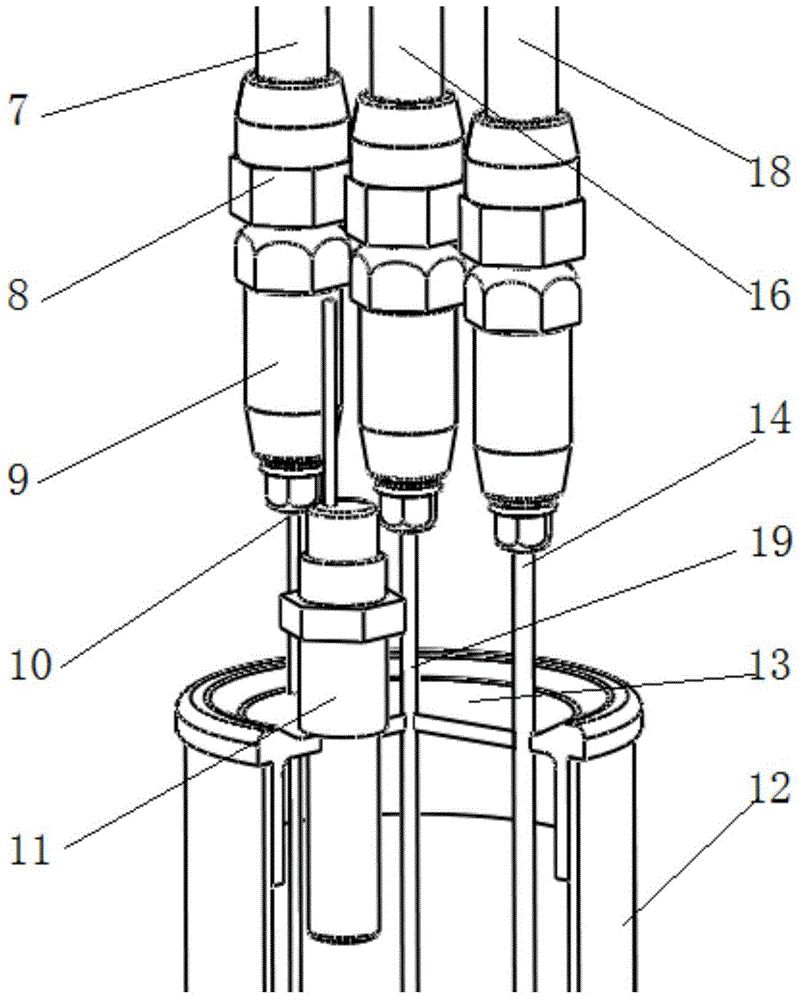

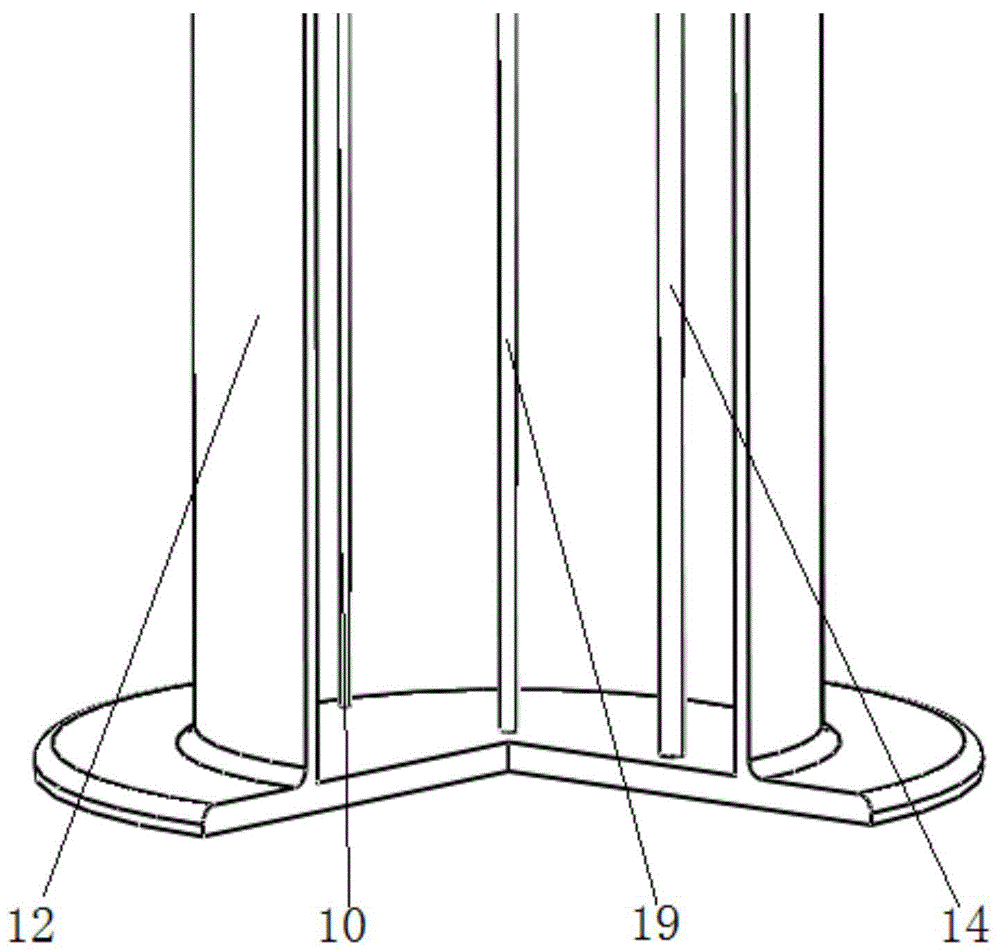

[0019] like Figure 1-Figure 5As shown, a device and method for evaluating the effectiveness of foam oil generation in the present invention includes digital flow type peristaltic pump I 1, digital flow type peristaltic pump II 2, digital flow type peristaltic pump III 3, gas flow meter I 4, gas Flow meter III 5, test stand 6, air supply hose III 7, ferrule joint 8, sealing connection joint 9, small diameter needle 10, non-contact ultrasonic continuous liquid level sensor 11, experimental container 12, container cover 13, large Diameter needle 14, camera 15, gas supply hose II16, gas flowmeter II 17, gas supply hose I 18, middle diameter needle 19, test control board 20, main switch 21, computer 22, wherein the digital flow type peristaltic The pump I 1, the air supply hose I 18, the ferrule joint 8, the sealing connection joint 9 and the large-diameter needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com