A method for detecting the curing quality of early-age concrete based on time domain reflection

A quality inspection method and technology of time domain reflection, which are applied in measurement devices, material inspection products, instruments, etc., can solve problems such as changing concrete, inability to obtain moisture content accurately, insufficient research on microwave and moisture content, etc., to improve efficiency, Save manpower and financial resources, the effect of small attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

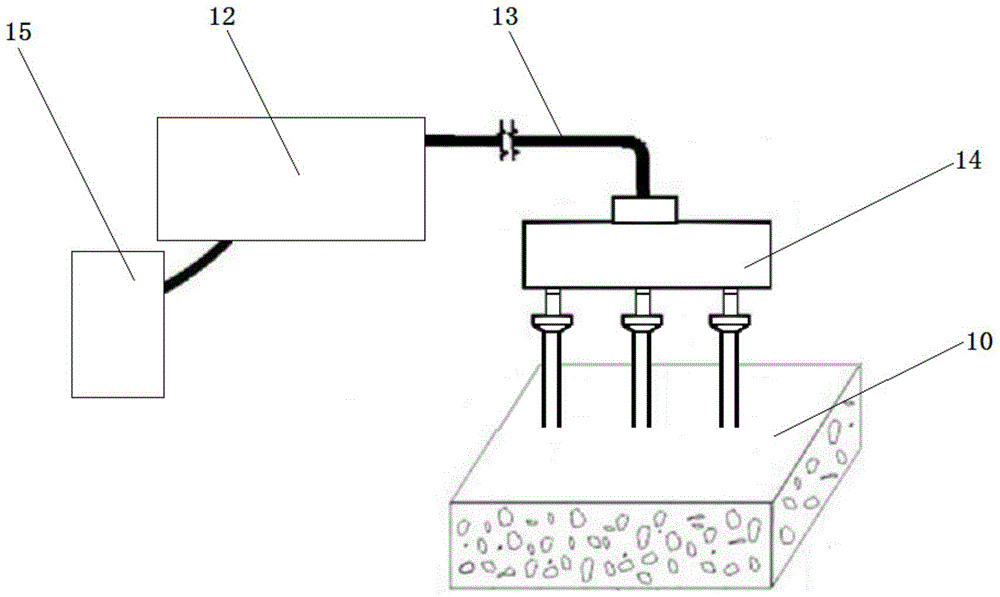

[0041] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0042] The invention provides a method for detecting the maintenance quality of early-age concrete based on time domain reflection, comprising the following steps:

[0043] S1, prepare the concrete test piece, and bury the probe pipe in the concrete test piece;

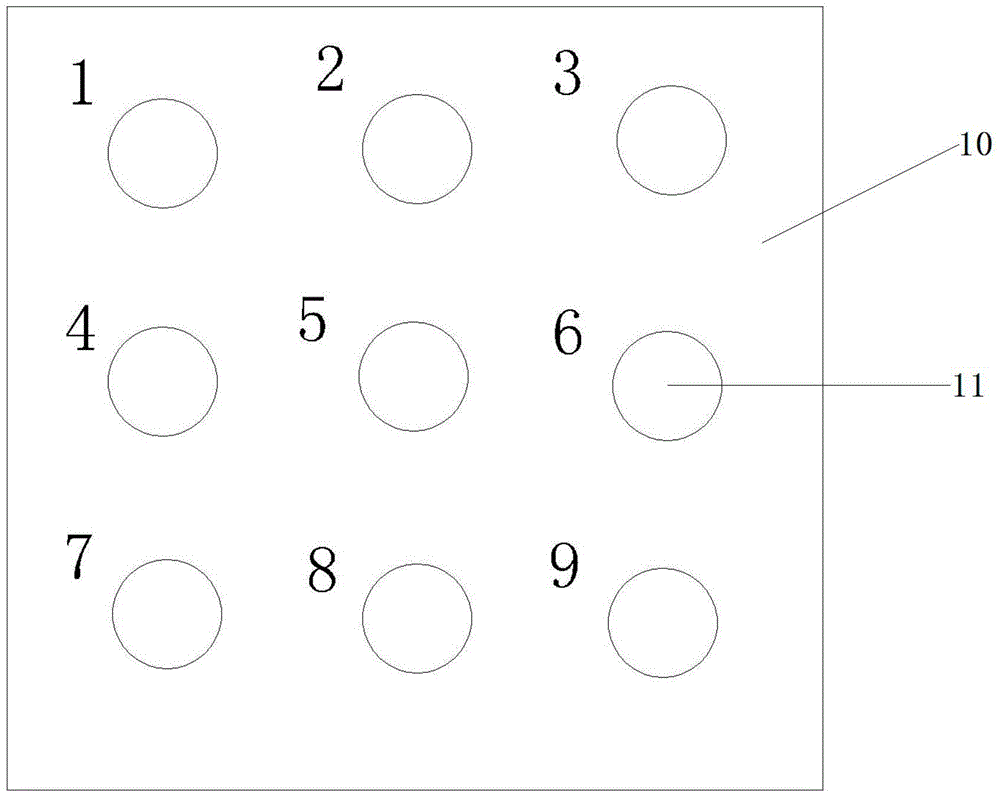

[0044] Prepare a certain amount of concrete according to the mix ratio of the concrete to be poured, and prepare 28 pieces of the same structure such as figure 1 The standard cubic sample 10 with a side length of 150 mm is shown, and 9 probe tubes 11 are buried in each sample 10, and the 9 probe tubes 11 are distributed in a matrix form of three rows and three columns. The probe tubes 11 adopt Brass rods; the 28 samples 10 are sorted according to the numbers A1-A28, and the 9 probe tubes 11 in each sample 10 are numbered 1-9 as shown in the figure;

[0045] S2. According to the curing conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com