Preparation method for graphene touch screen

A graphene and touch screen technology, applied in the field of graphene touch screen preparation, can solve problems such as easy damage, inability to remove silver flakes, short circuit, surface dirt, easy scratches, etc., and achieve the effect of avoiding the increase of square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

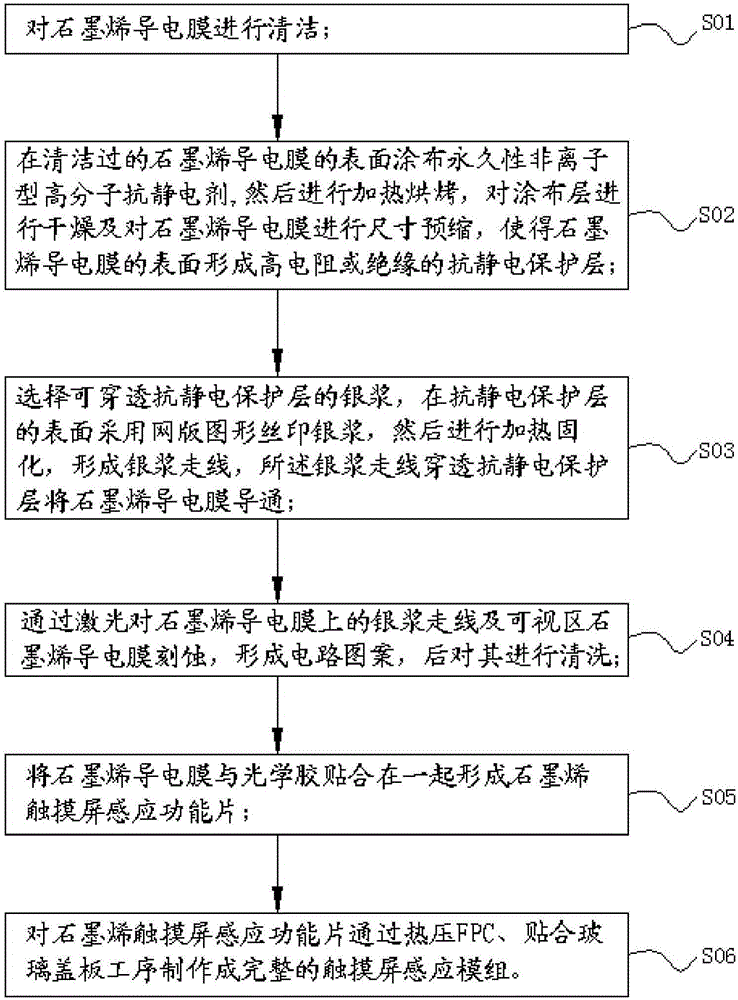

[0026] Such as figure 1 Shown, the present invention comprises the following steps:

[0027] S01, cleaning the graphene conductive film;

[0028] S02, coating a permanent non-ionic macromolecule antistatic agent on the surface of the cleaned graphene conductive film, then heating and baking, drying the coating layer and preshrinking the graphene conductive film, Form a high-resistance or insulating antistatic protective layer on the surface of the vinyl conductive film;

[0029] S03, select the silver paste that can penetrate the antistatic protective layer, use screen printing silver paste on the surface of the antistatic protective layer, and then heat and cure to form silver paste wiring, and the silver paste w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com