Flexible circuit board

A circuit board and circuit layer technology, applied in printed circuits, printed circuits, circuit thermal devices, etc., can solve problems such as troublesome, poor heat dissipation, and difficult installation, and achieve the effect of improving heat dissipation devices and good heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

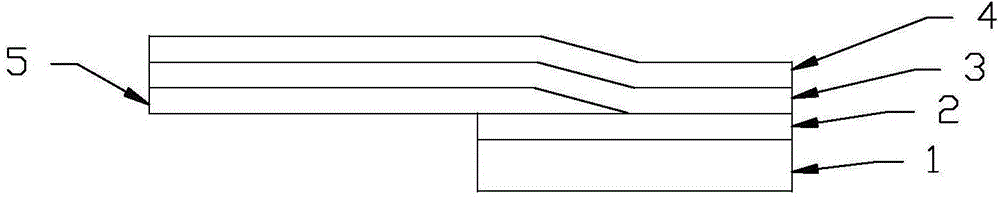

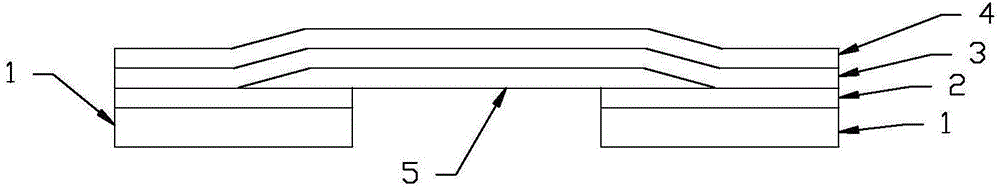

[0021] The second embodiment: if figure 2 As shown, the flexible circuit board is a single-layer circuit board, and the hard substrate 1 is at least two, figure 2 There are two pieces of the first flexible base material layer 5, and at least one piece of the first flexible base material layer 5, and the two sides of each first flexible base material layer 5 are connected to two hard substrates 1 respectively. That is, both sides are hard substrates, and the hard substrates are connected together through the first flexible substrate layer 5 .

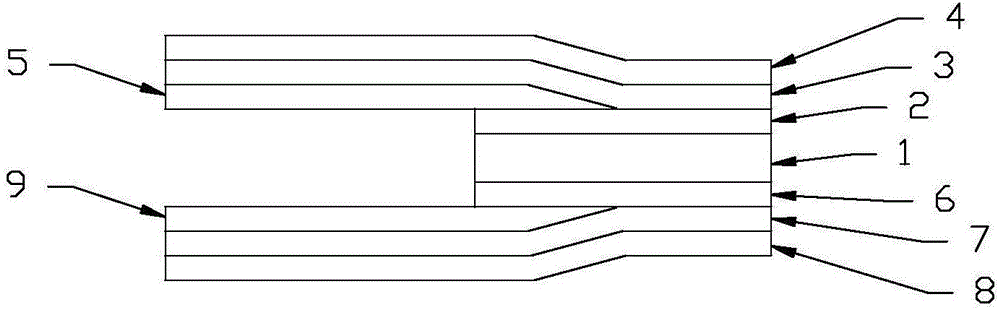

[0022] The flexible circuit board is a double-layer circuit board, and the hard substrate 1 is also provided with a second heat dissipation insulating adhesive layer 6, a second circuit layer 7 and a second insulating solder resist layer 8 in sequence. The flexible circuit board also includes a second flexible base material layer 9, the second circuit layer 7 extends from the second heat dissipation insulating adhesive layer 8 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com