Polishing device, method for applying polishing pad, and method for replacing polishing pad

A technology for grinding devices and grinding pads, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc., can solve problems such as deformation of grinding tables, and achieve the effects of easy replacement operation, labor-saving stripping operation, and high-precision replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

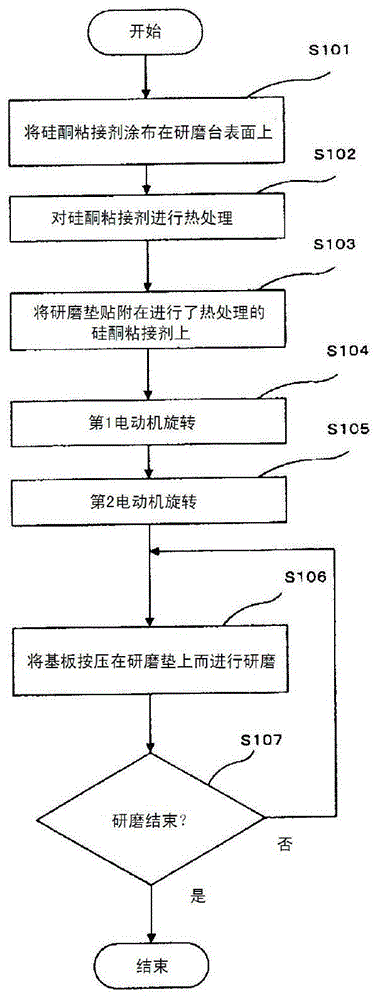

[0111] Next, a polishing device and a polishing pad replacement method according to a first embodiment of the present invention will be described with reference to the accompanying drawings. In the following embodiments, a CMP (Chemical Mechanical Polishing: Chemical Mechanical Polishing) polishing device will be described as an example, but it is not limited thereto.

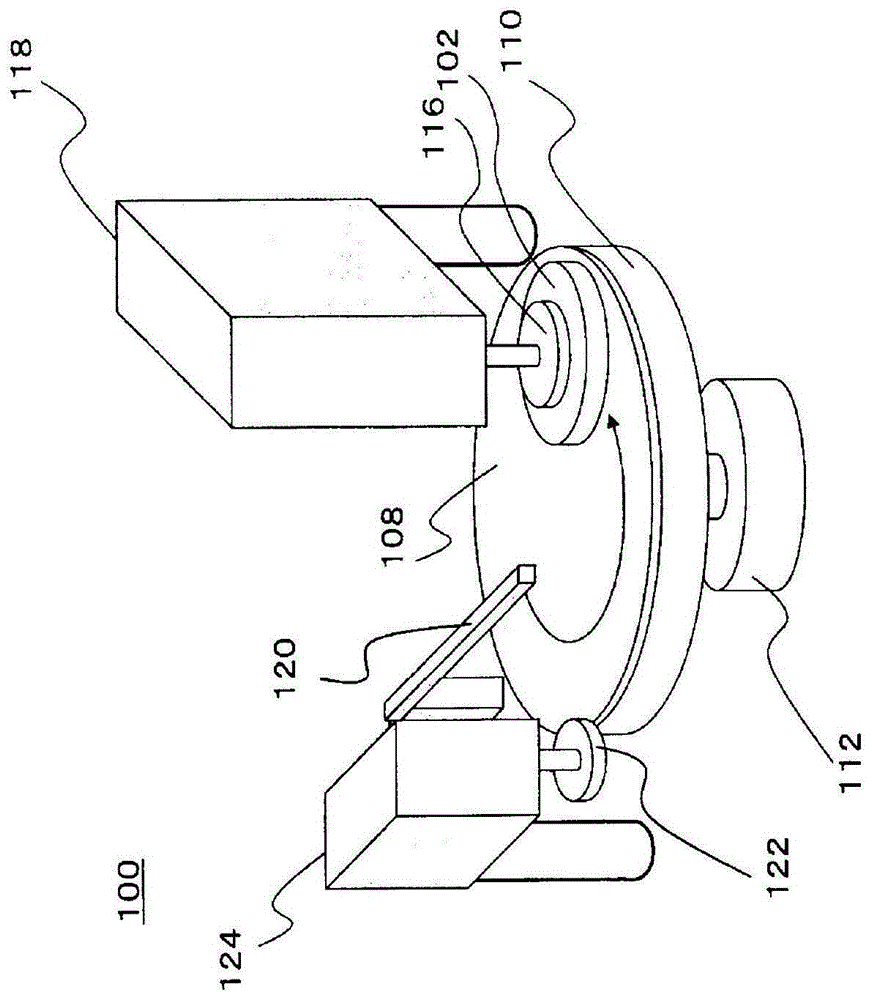

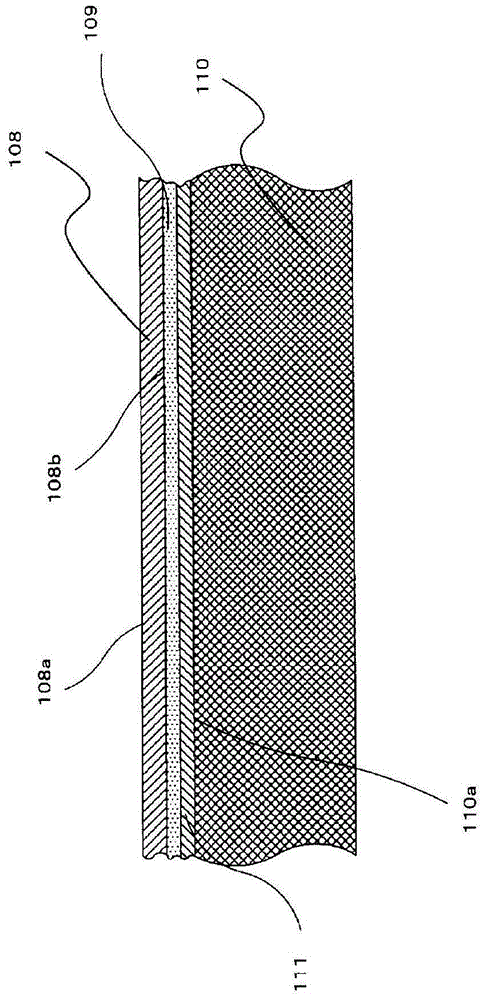

[0112] figure 1 It is a figure which schematically shows the whole structure of the polishing apparatus of 1st Embodiment. Such as figure 1 Shown, grinding device 100 has: grinding table 110, and the upper surface of this grinding table 110 can be installed the polishing pad 108 that is used for grinding substrate 102 such as semiconductor wafer; drive; a top ring 116 capable of holding the substrate 102 ; and a second motor 118 for rotationally driving the top ring 116 .

[0113] In addition, the polishing apparatus 100 has: a slurry line 120, which supplies the grinding fluid containing the abrasive materi...

no. 2 Embodiment approach

[0137] Next, a polishing device and a polishing pad replacement method according to a second embodiment of the present invention will be described with reference to the accompanying drawings. In the following embodiments, a CMP (Chemical Mechanical Polishing: Chemical Mechanical Polishing) polishing device will be described as an example, but it is not limited thereto. In addition, the polishing device and the polishing pad replacement method of the second embodiment may be implemented in combination with the polishing device and the polishing pad replacement method of the first embodiment described above.

[0138] Figure 4 It is a figure which schematically shows the whole structure of the polishing apparatus of 2nd Embodiment. Such as Figure 4 As shown, the grinding device 1100 has: a grinding table 1110, the upper surface of which can be installed with a grinding pad 1108 for grinding substrates 1102 such as semiconductor wafers; a first motor 1112, which rotates the gr...

no. 3 Embodiment approach

[0181] Figure 11 is a diagram schematically showing the overall structure of the polishing device. Such as Figure 11 As shown, the grinding device 2100 has: a grinding table 2110, the upper surface of which can be installed with a grinding pad 2108 for grinding substrates 2102 such as semiconductor wafers; a first motor 2112, which rotates the grinding table 2110 drive; the top ring 2116, the top ring 2116 can hold the substrate 2102; and the second motor 2118, the second motor 2118 rotates and drives the top ring 2116.

[0182] In addition, the polishing apparatus 2100 has: a slurry line 2120, which supplies a polishing slurry containing abrasive materials onto the upper surface of the polishing pad 2108; and a dressing tool unit 2124, which has 2108 Dressing tool disc 2122 for trimming (filing trimming).

[0183] In addition, the polishing device 2100 has: an operation panel 2130, which is used to input various operation commands and output various information about the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com