Artificial granite waste gas treatment system

A technology for waste gas treatment and artificial granite, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The concentration of dust and odor, and the effect of preventing physical diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

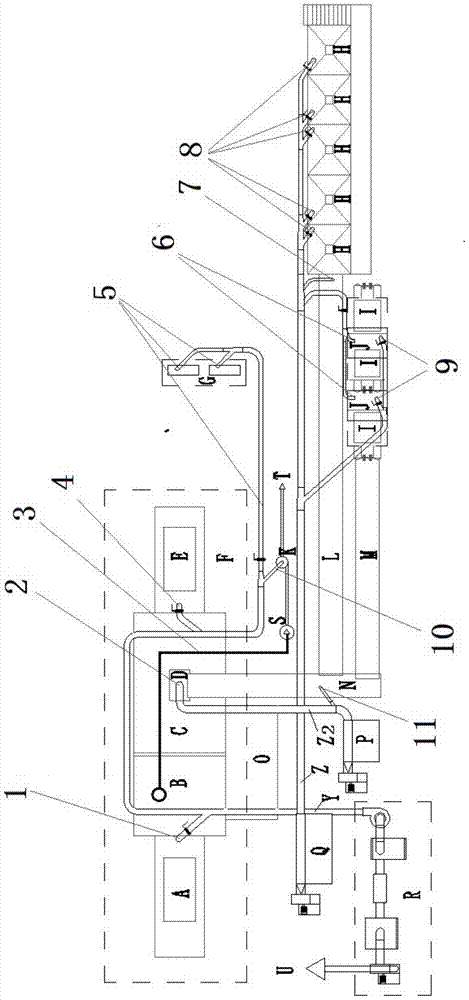

[0014] like figure 1 As shown, the artificial granite waste gas treatment system of the present invention includes a block car A, a press room B, a cloth room C, a large mixer D, a cloth car E, a pressing workshop F, a sewer circulating pool G, a material silo and Dust collection cover H, color mixer I, material silo J, moisture separator K, feeding belt L, M, N, central control room O, bag filter P, Q, dust suction pipe Z, Z2; Gas reaction system R, vacuum pump S, drain pipe T, exhaust pipe U; odor suction branch pipe ports 1, 3, 4, 5, 10; dust suction branch pipe ports 2, 6, 7, 8, 9, 11 devices and parts , can be obtained by manufacturing or purchasing by using the prior art. The artificial granite waste gas treatment system of the present invention can be assembled using the prior art.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com