Automobile gas tank rolling machine

A technology of a gas storage tank and a rolling machine, which is applied in the field of automobiles, can solve the problems of low processing efficiency and can not meet production needs, etc., and achieves the effect of improving time and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

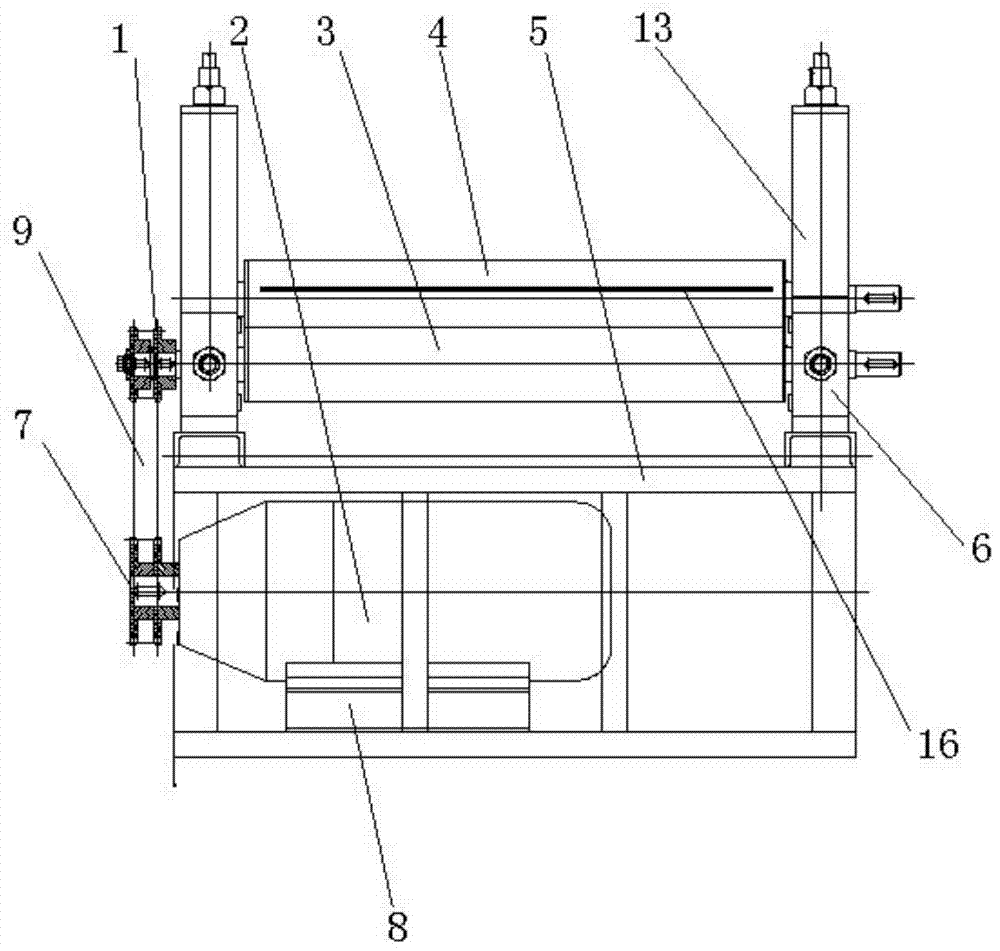

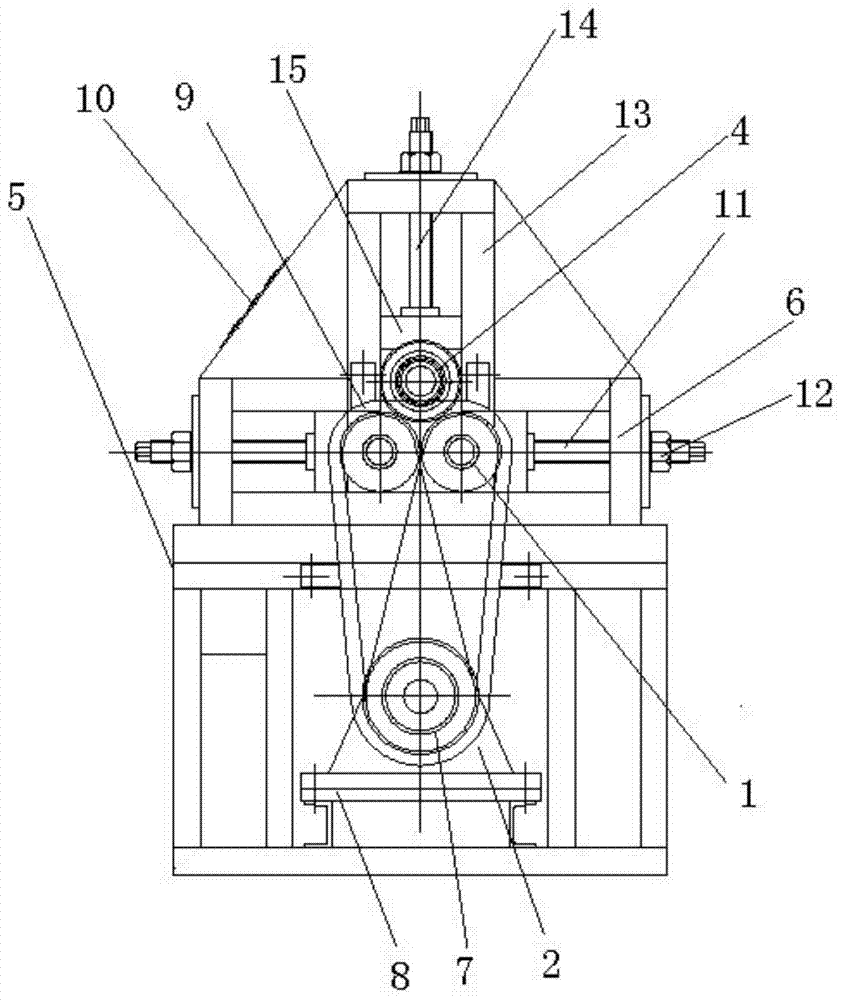

[0012] Such as figure 1 and figure 2 As shown, the rolling machine for automobile gas storage tank includes a reducer 2, a lower roller 3, and an upper roller 4. The reducer 2 is installed on a machine base 8, and the machine base 8 is located in the base 5. The output shaft of the reducer 2 is provided with The main sprocket 7, two opposite lower roller brackets 6 are installed on the base 5, the two ends of the two lower rollers 3 are installed on the relative lower roller brackets 6 in parallel through the roller seat, the two lower rollers 3 are connected with the main chain One end corresponding to the wheel 7 is provided with a slave sprocket 1, which is connected with the main sprocket 7 through a chain 9; Mounted on two opposite upper roller brackets 13 by the roller seat, a groove 16 with a triangular cross section is milled on the peripheral surface of the upper roller 4 along the axial direction.

[0013] Both ends of the lower roller support 6 are horizontally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com