Welding process quality evaluation method for shielded metal arc welding

A technology of electrode arc welding and welding process, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., and can solve the problems of difficult quantitative evaluation of welding process quality, lack of reliable standards, and different physical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

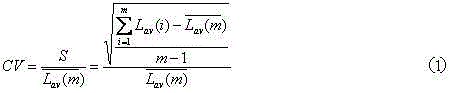

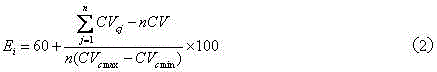

Method used

Image

Examples

Embodiment Construction

[0041] The content of the welding process quality evaluation method of the present invention will be further described below in conjunction with specific examples. The embodiments are only for illustrating the technical concept and features of the present invention, and should not limit the protection scope of the present invention. All equivalent changes or modifications on the basis of the present invention shall fall within the protection scope of the present invention.

[0042] In this embodiment, the J422 electrode is specifically used for the flat welding operation of the arc welding, so as to perform quantitative evaluation of the welding quality on the welding process.

[0043] First, the welding voltage and welding current sensors are used to obtain welding process information. The welding voltage and welding current pass through the Hall sensor respectively, and after being processed by the signal conditioning circuit, they are transformed into a voltage signal of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com