Seasonal high turbidity raw water processing technology

A processing, seasonal technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

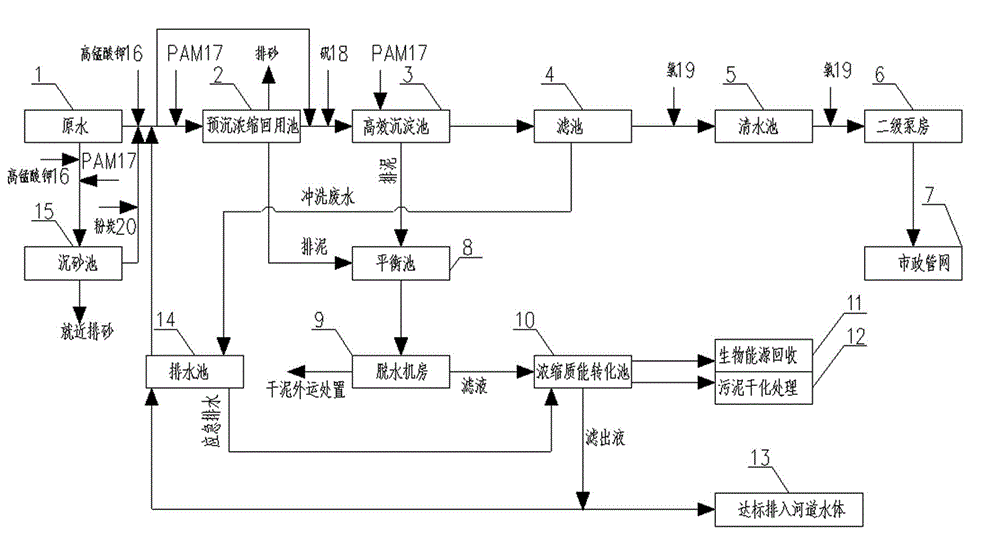

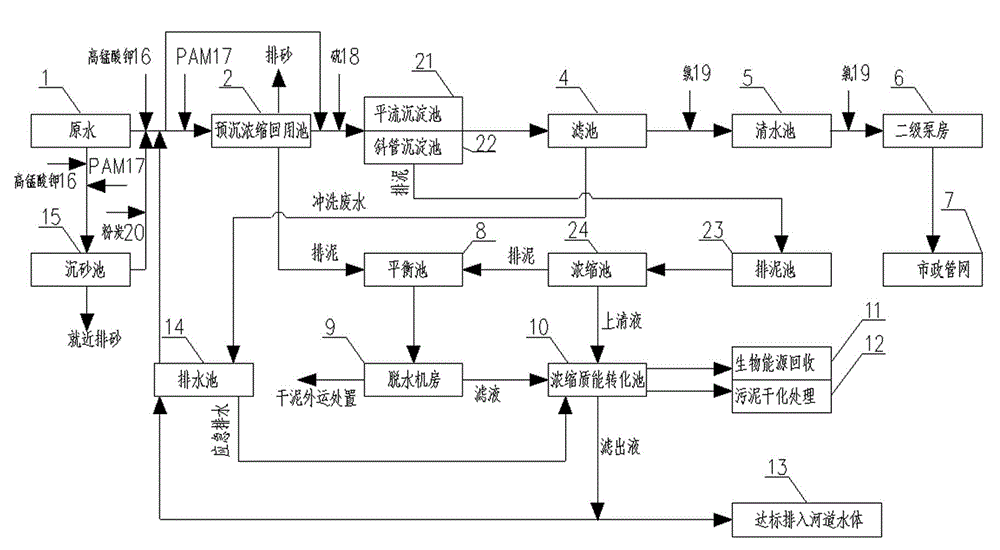

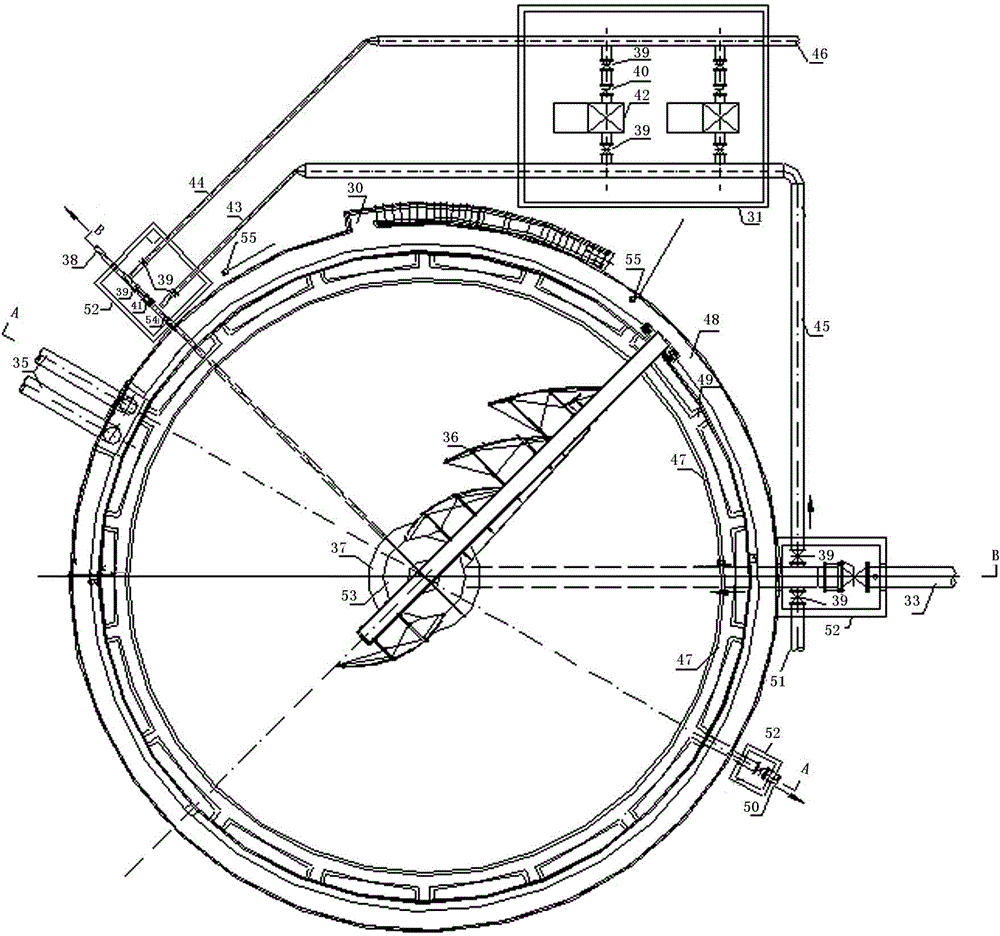

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The present invention is a seasonal high turbidity water treatment process. First, according to the conditions of water plant land and funds, the treatment process is divided into high-efficiency sedimentation tanks for seasonal high turbidity water treatment processes and advection sedimentation tanks or inclined tube sedimentation tanks. There are two types of seasonal high turbidity water treatment processes. When the site of the water plant is tight and the construction funds are relatively abundant, the sedimentation process can consider adopting a high-efficiency sedimentation tank with a small footprint and the function of sludge return and concentration; when the land for the water plant is relatively abundant and the construction funds are relatively tight, the sedimentation process can be considered Use advection sedimentation tanks or inclined tube se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com