Glue used in gravel road paving, and application method thereof

A technology for paving gravel roads and application methods, which is applied in the direction of condensed pavements, roads, roads, etc., which are laid on site, can solve the problems of large increase in the pressure of drainage pipes, easy to accumulate water on the road surface, and difficult to dry, etc. The effect of noise, less usage, comfortable walking feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A glue for paving gravel roads, the glue is composed of polyurethane A material and polyurethane B material in a weight ratio of 5:4,

[0028] The weight percent of each component of polyurethane type A material is:

[0029] Trihydroxypolyether 330N, 70%;

[0030] Vinyl polymer grafted polyether polyol POP36 / 30, 10%;

[0031] Polyether GE-305, 20%;

[0032] It should be noted that 330N means polyether polyol with molecular weight up to 4800, POP36 / 30, 36 means POP viscosity is less than 3600, 30 means POP hydroxyl value is 30±2, GE-305 means product model.

[0033] The weight percentage of each component of polyurethane B material is:

[0034] 4,4'-Diphenylmethane diisocyanate, 50%;

[0035] Hydrogenated phenylmethane diisocyanate, 50%.

[0036] Polyurethane material A and polyurethane material B undergo an addition reaction to form the above polyurethane glue. The polyurethane glue is an odorless, light yellow viscous liquid. In order to determine the curing time ...

Embodiment 2

[0038] A glue for paving gravel roads, the glue is composed of polyurethane A material and polyurethane B material in a weight ratio of 5:4,

[0039] The weight percent of each component of polyurethane type A material is:

[0040] Trihydroxypolyether 330N, 70%;

[0041] Vinyl polymer grafted polyether polyol POP36 / 30, 10%;

[0042] Polyether GE-305, 20%;

[0043] The weight percentage of each component of polyurethane B material is:

[0044] 4,4'-Diphenylmethane diisocyanate, 60%;

[0045] Hydrogenated phenylmethane diisocyanate, 40%.

[0046] The performance of this glue is with embodiment 1.

Embodiment 3

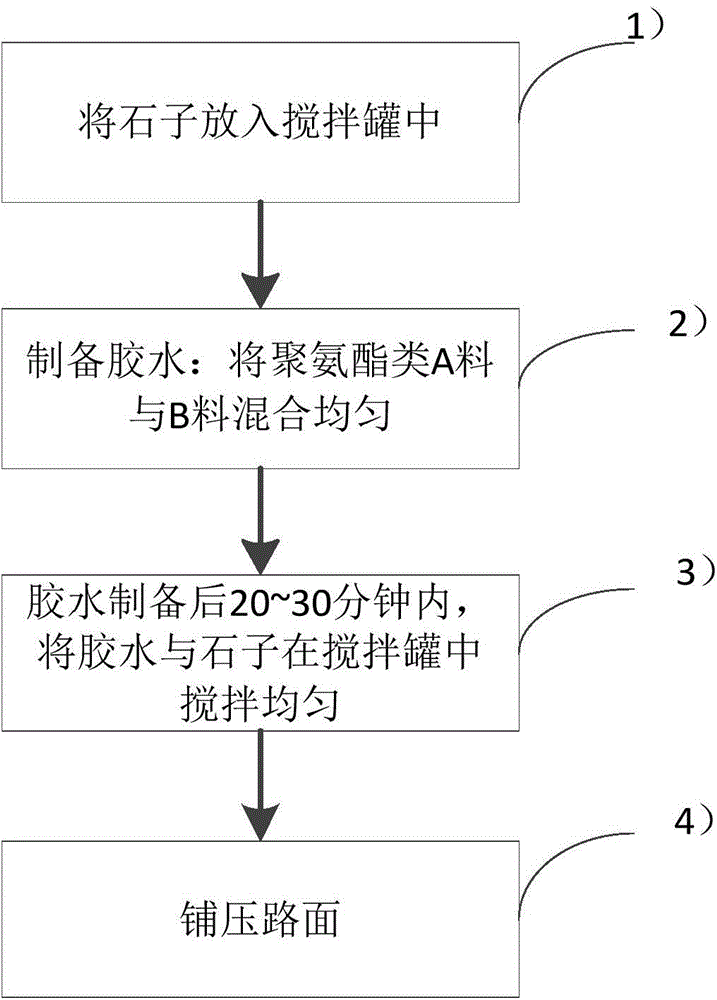

[0048] The present embodiment provides a kind of method that above-mentioned polyurethane glue is applied in paving stone road, please refer to figure 1 As shown, it is a flowchart of the application method, and the specific steps are:

[0049] 1) Put the stones used for paving into the mixing tank;

[0050] 2) Prepare the glue:

[0051] Preparation of polyurethane type A material: Mix trihydroxy polyether 330N, vinyl polymer grafted polyether polyol POP36 / 30 and polyether GE-305 in a weight ratio of 7:1:2, and stir evenly to form polyurethane type A material;

[0052] Preparation of polyurethane material B: Mix 4,4'-diphenylmethane diisocyanate and hydrogenated phenylmethane diisocyanate at a weight ratio of 1:1, stir evenly to become polyurethane material B;

[0053] Mix the polyurethane type A material with the polyurethane type B material, stir for 10-15 minutes until uniform, and become polyurethane type glue;

[0054] 3) After preparing the glue, stir the glue and th...

PUM

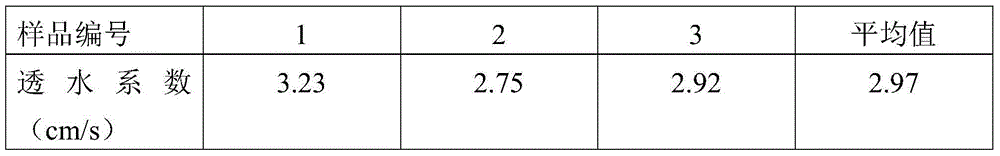

| Property | Measurement | Unit |

|---|---|---|

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com