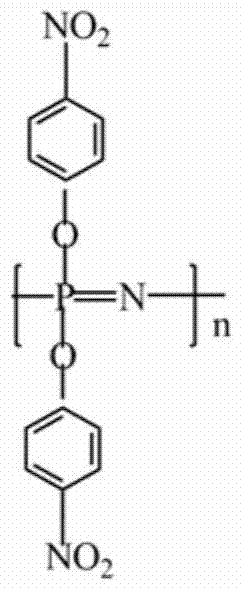

Nitropolyphenoxyphosphazene and its preparation method

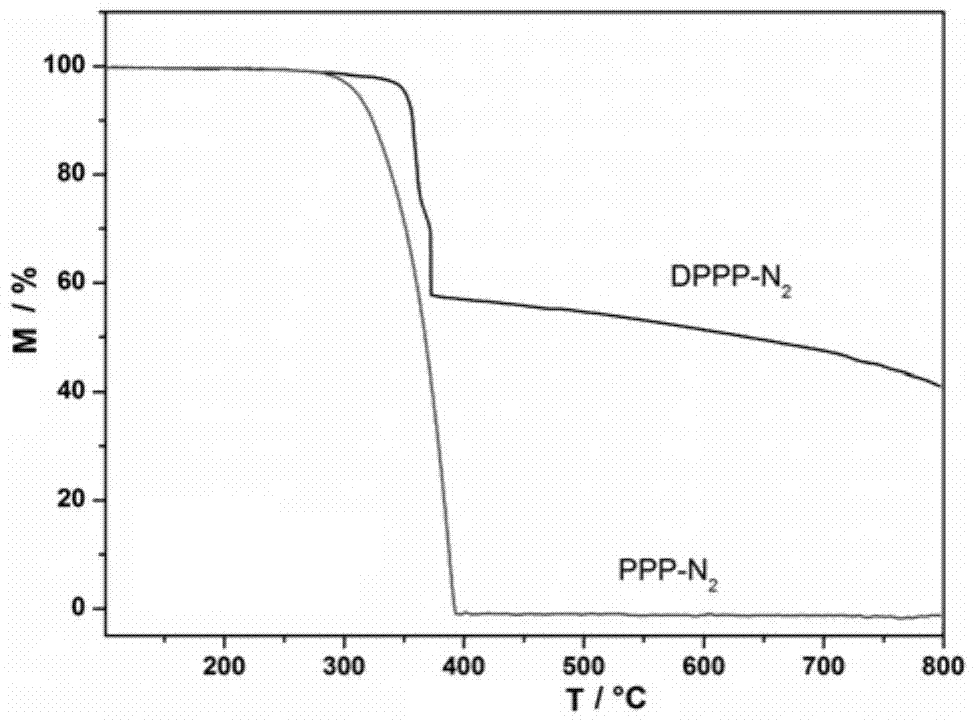

A technology of nitropolyphenoxyphosphazene and polyphenoxyphosphazene is applied in the field of polyphosphazene flame retardant and its preparation, which can solve the problems of low carbon residue, poor stability and the like, and achieve the improvement of nitrogen content, The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First take by weighing 35g of nitric acid (concentration is 65%, 0.36mol) with Erlenmeyer flask, then slowly add 24g of sulfuric acid (concentration is 98%, 0.24mol) while stirring under the condition of ice-water bath, mix well. Add 3.5 g of polyphenoxyphosphazene to a 100 ml three-neck flask equipped with a stirring paddle and a reflux condensing device, and the polyphenoxyphosphazene was purchased from Beijing Xinhui Technology Co., Ltd. Under the condition of ice-water bath, slowly add the mixed acid into the three-necked flask, nitric acid: polyphenoxyphosphazene = 10:1. The reaction temperature is maintained at 30°C. After 4 hours of reaction, wash with sodium hydroxide solution to pH = 7.0, then wash with distilled water until the color of the solution is colorless and transparent, and then filter and dry to obtain white powdery nitropolyphenylene oxide. Phosphazene 3.89g.

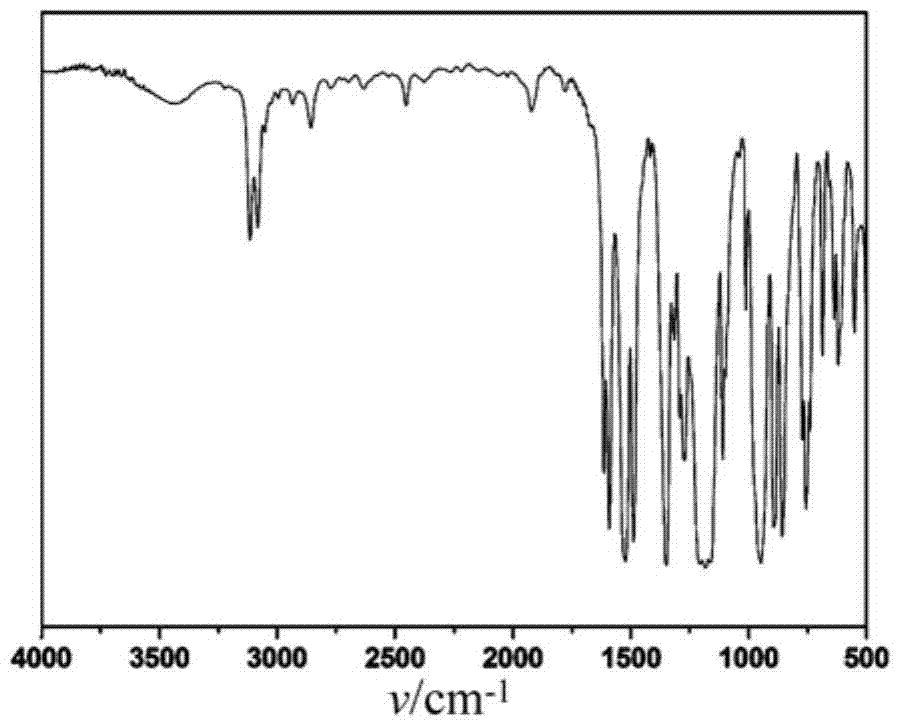

[0030] It can be seen from the infrared spectrum of nitropolyphenoxyphosphazene that 127...

Embodiment 2

[0032] First take by weighing 35g of nitric acid (concentration is 65%, 0.36mol) with Erlenmeyer flask, then slowly add 24g of sulfuric acid (concentration is 98%, 0.24mol) while stirring under the condition of ice-water bath, mix well. Add 3.5 g of polyphenoxyphosphazene to a 100 ml three-neck flask equipped with a stirring paddle and a reflux condensing device, and the polyphenoxyphosphazene was purchased from Beijing Xinhui Technology Co., Ltd. Under the condition of ice-water bath, slowly add the mixed acid into the three-necked flask, nitric acid: polyphenoxyphosphazene = 10:1. The reaction temperature is maintained at 40°C. After 4 hours of reaction, wash with sodium hydroxide solution to pH = 7.0, then wash with distilled water until the color of the solution is colorless and transparent, and then filter and dry to obtain white powdery nitropolyphenylene oxide. Phosphazene 4.19g.

Embodiment 3

[0034] First take by weighing 35g of nitric acid (concentration is 65%, 0.36mol) with Erlenmeyer flask, then slowly add 24g of sulfuric acid (concentration is 98%, 0.24mol) while stirring under the condition of ice-water bath, mix well. Add 3.5 g of polyphenoxyphosphazene to a 100 ml three-neck flask equipped with a stirring paddle and a reflux condensing device, and the polyphenoxyphosphazene was purchased from Beijing Xinhui Technology Co., Ltd. Under the condition of ice-water bath, slowly add the mixed acid into the three-necked flask, nitric acid: polyphenoxyphosphazene = 10:1. The reaction temperature is maintained at 50°C. After 4 hours of reaction, wash with sodium hydroxide solution to pH = 7.0, then wash with distilled water until the color of the solution is colorless and transparent, and then filter and dry to obtain white powdery nitropolyphenylene oxide. Phosphazene 4.21g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com