Noctilucent coated rope end and production method thereof

A luminous coating and rope head technology, applied in the field of clothing accessories, can solve the problems of easy falling off, high development cost, poor hand feeling, etc., and achieve the effects of good adhesion, rich colors, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

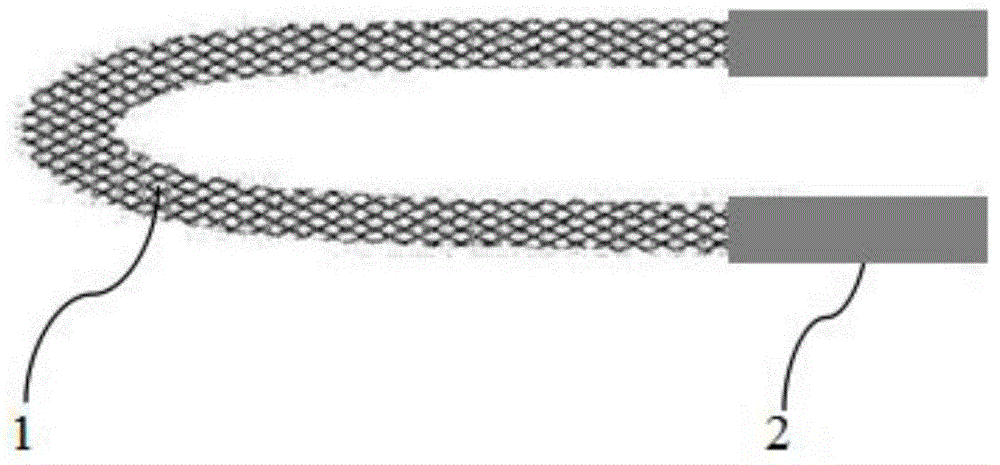

[0055] A monochromatic luminous-coated rope end, such as image 3 As shown, it includes a white rope 1, and the end 2 of the rope is successively provided with a primer ink layer 4 and a luminous ink layer 3 (such as Figure 4 As shown), the color of the primer ink layer is red, the total length of the rope is 1500mm, and the end length is 30mm.

[0056] The schematic diagram of the effect of the rope head is as follows: Figure 7 As shown, when in a bright environment, the end of the rope (30mm) is red; when in a dark environment, the end of the rope (30mm) will emit yellow-green light.

[0057] The preparation method of the monochromatic luminous coating rope head is as follows:

[0058] (1) Ink adjustment:

[0059] Primer ink (red) is prepared from the following raw materials in parts by weight:

[0060]

[0061] Under stirring, first add the red water-based color paste into the water, and disperse evenly; then slowly add this mixture into FY-160; then add FOMEX 810,...

Embodiment 2

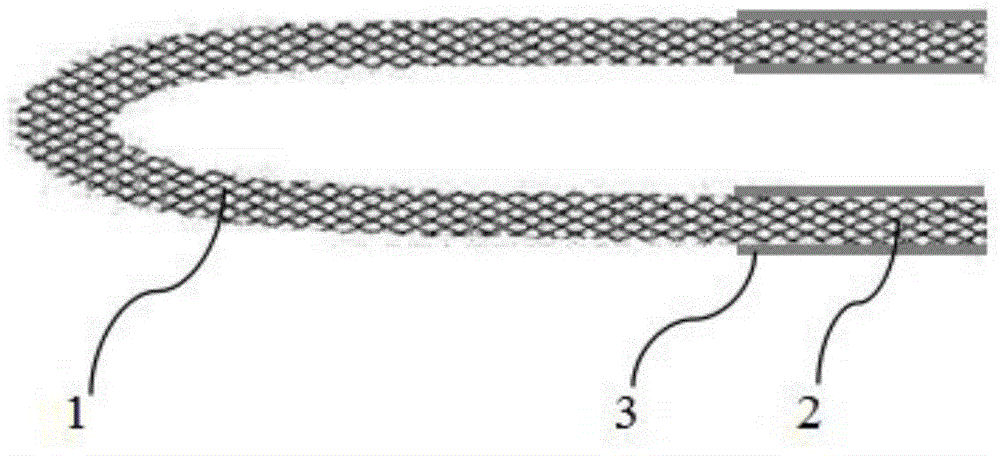

[0073] A two-color luminous-coated rope head, as attached Figure 5 As shown, it includes a white rope 1, and the end 2 of the rope is provided with a primer ink layer and a luminous ink layer in sequence. The colors of the primer ink layer are 10mm yellow and 20mm red along the direction from the middle of the rope to the end. , the total length of the rope is 1500mm, the length of the end is 30mm, and the length of the luminous ink layer is 20mm.

[0074] The schematic diagram of the effect of the rope head is as follows: Figure 8 As shown, the end of the rope head is 10mm yellow and 20mm red in the direction from the middle of the rope to the end; when in a dark environment, the end of the rope (20mm) will emit yellow-green light.

[0075] The preparation method of the two-color luminous coating rope head is as follows:

[0076] (1) Ink adjustment:

[0077] Primer ink (yellow) is prepared from the following raw materials in parts by weight:

[0078]

[0079]

[0...

Embodiment 3

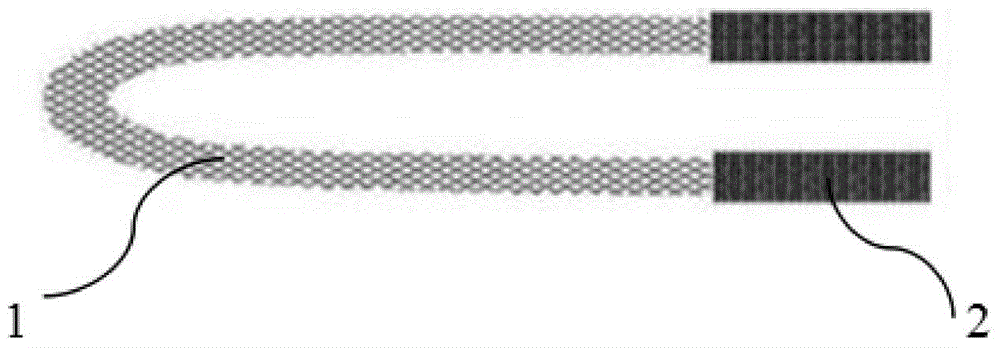

[0093] A multicolored luminous-coated rope end, such as Image 6 As shown, it includes a white rope 1, and the end 2 of the rope is provided with a primer ink layer and a luminous ink layer. The colors of the primer ink layer are 10mm yellow, 10mm white and 10mm along the direction from the middle of the rope to the end. Red, the total length of the rope head is 1500mm, the length of the end is 30mm, and the length of the luminous ink layer is 20mm.

[0094] The schematic diagram of the effect of the rope head is as follows: Figure 9 As shown, when in a bright environment, the end of the rope head is 10mm yellow, 10mm white and 10mm red along the middle of the rope toward the end; when in a dark environment, the end of the rope is along the middle of the rope. The end direction is sequentially 10 mm yellow-green light, 10 mm dark and 10 mm yellow-green light.

[0095] The preparation method of the multi-color luminous rope head is as follows:

[0096] (1) Ink adjustment: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com