Solar spectrum selective absorptive coating and manufacturing method thereof

A technology for absorbing coatings and solar spectra, applied in coatings, solar thermal devices, solar thermal power generation, etc., can solve the problems of lower absorptivity of film systems, achieve low thermal radiation rate, increase solar spectral absorptivity, and process stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

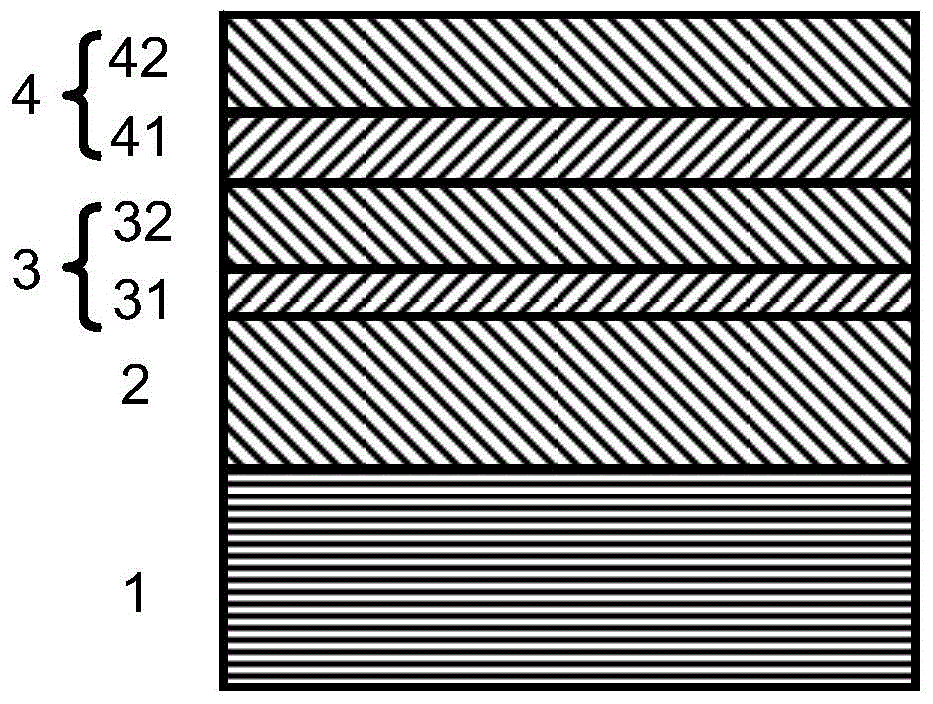

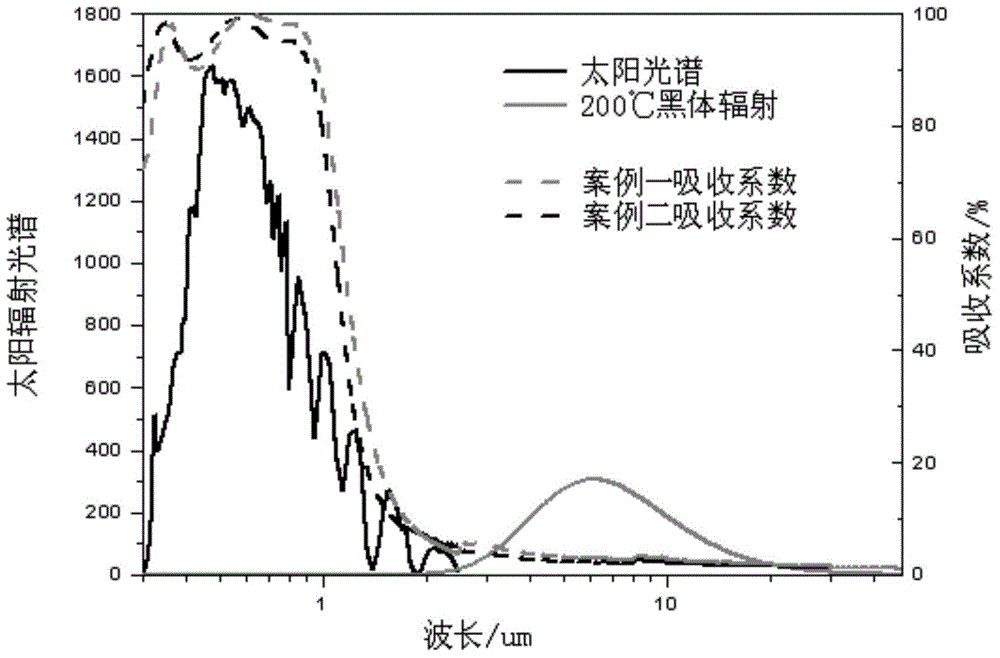

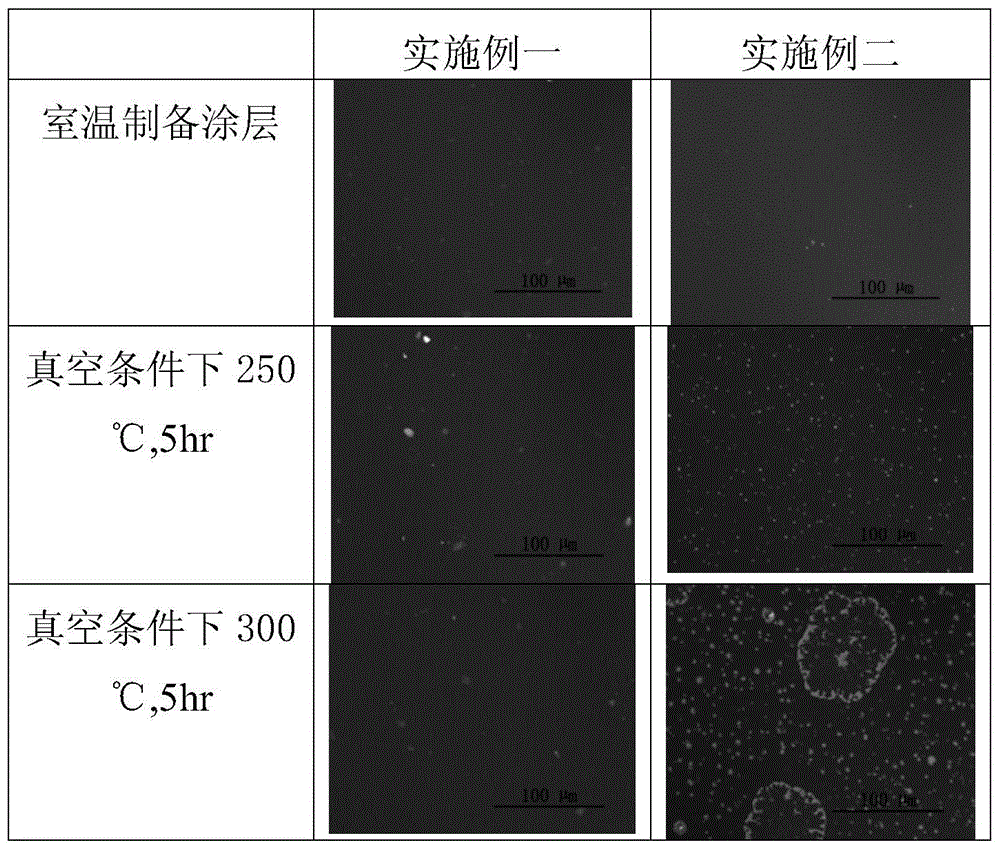

[0039] The preparation of the absorbing layer is to prepare the absorbing layer Ti and Ge sequentially on the above-mentioned infrared reflective layer by (pulse) DC magnetron sputtering method. %above).

[0040] The preparation of the anti-reflection layer is to prepare the anti-reflection layer on the above-mentioned absorbing layer by (pulse) DC reactive magnetron sputtering. %wt, purity over 99.7%).

Embodiment 1

[0042] Table 1 is prepared by magnetron sputtering method (SiO 2 / TiO 2 / Ge / Ti / Al / substrate) process-controlled thickness of each monolayer in the spectrally selective absorption coating.

[0043] The process control thickness of each monolayer film of table 1 embodiment one

[0044]

[0045] Carry out embodiment one coating preparation according to above-mentioned preparation method, concrete operation steps are as follows:

[0046]1) Cleaning of the glass substrate: firstly, use a neutral detergent to clean the glass substrate; then, in the film feeding chamber of the coating equipment, bombard the surface of the glass substrate with a radio frequency ion source for secondary cleaning, and the process parameters are set as follows: radio frequency The sputtering power of the power supply is 200w, the flow rate of the working gas Ar (purity 99.99%) is 45sccm, the working pressure is 9.8×10-2mTorr, and the sputtering time is 360s.

[0047] 2) The glass substrate is trans...

Embodiment 2

[0055] Table 2 is prepared by magnetron sputtering method (SiO 2 / TiO 2 / Ge / Al / substrate) process-controlled thickness of each monolayer in the spectrally selective absorbing coating.

[0056]

[0057] The process control thickness of each monolayer film of table 2 embodiment two

[0058] Carry out embodiment two coating preparation according to above-mentioned preparation method, concrete operation steps are as follows:

[0059] 1) Cleaning of the glass substrate: firstly, use a neutral detergent to clean the glass substrate; then, in the film feeding chamber of the coating equipment, bombard the surface of the glass substrate with a radio frequency ion source for secondary cleaning, and the process parameters are set as follows: radio frequency The sputtering power of the power supply is 200w, the flow rate of the working gas Ar (purity 99.99%) is 45sccm, the working pressure is 9.8×10-2mTorr, and the sputtering time is 360s.

[0060] 2) The glass substrate is transpor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com