Detection method of residual cladding thickness of side-polished fiber

A detection method and residual packet technology, which can be used in measurement devices, optical devices, instruments, etc., can solve the problems of poor curve linearity and large influence, and achieve the effect of eliminating measurement errors and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] A method for detecting the remaining cladding thickness of a side-polished optical fiber, comprising the following steps:

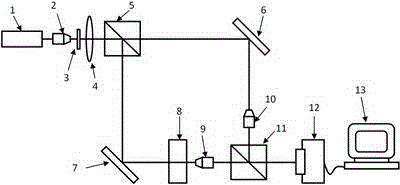

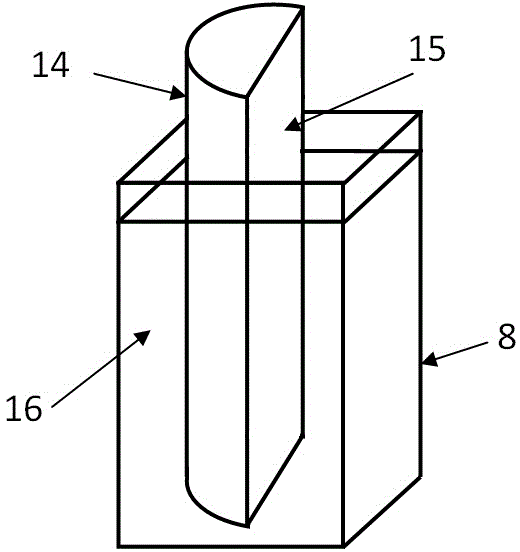

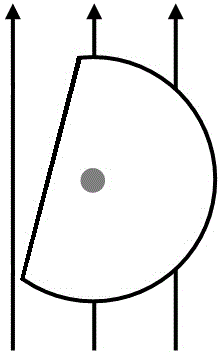

[0076] (1) A Mach-Zehnder type transmission off-axis holographic imaging system is adopted to shoot an off-axis hologram including the structural information of the polished optical fiber; the Mach-Zehnder type transmission off-axis holographic imaging experimental system includes a laser, and the laser emitted by the laser After beam expansion and collimation, it is divided into two beams by the beam splitter. The first beam passes through the first plane mirror to the beam combiner, and the second beam passes through the second plane mirror and the sample cell to the beam combiner. The beam combiner will The two beams of light are combined and incident on the CCD camera, which is connected to the image processing device; the side-polished optical fiber is placed in a sample pool filled with a refractive index matching liquid, and the polished opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com