Integration device for collecting lateral seepage of rice field and overland runoff

A surface runoff and seepage technology, applied in the direction of sampling devices, etc., can solve the problems of large measurement results of nutrient content of lateral seepage, no consideration of interception of lateral seepage on the opposite side of the field ridge, and large repeated investment in manpower and material resources, etc., to achieve accurate Objectively evaluate, improve the actual utilization rate, and avoid the effect of repeated investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

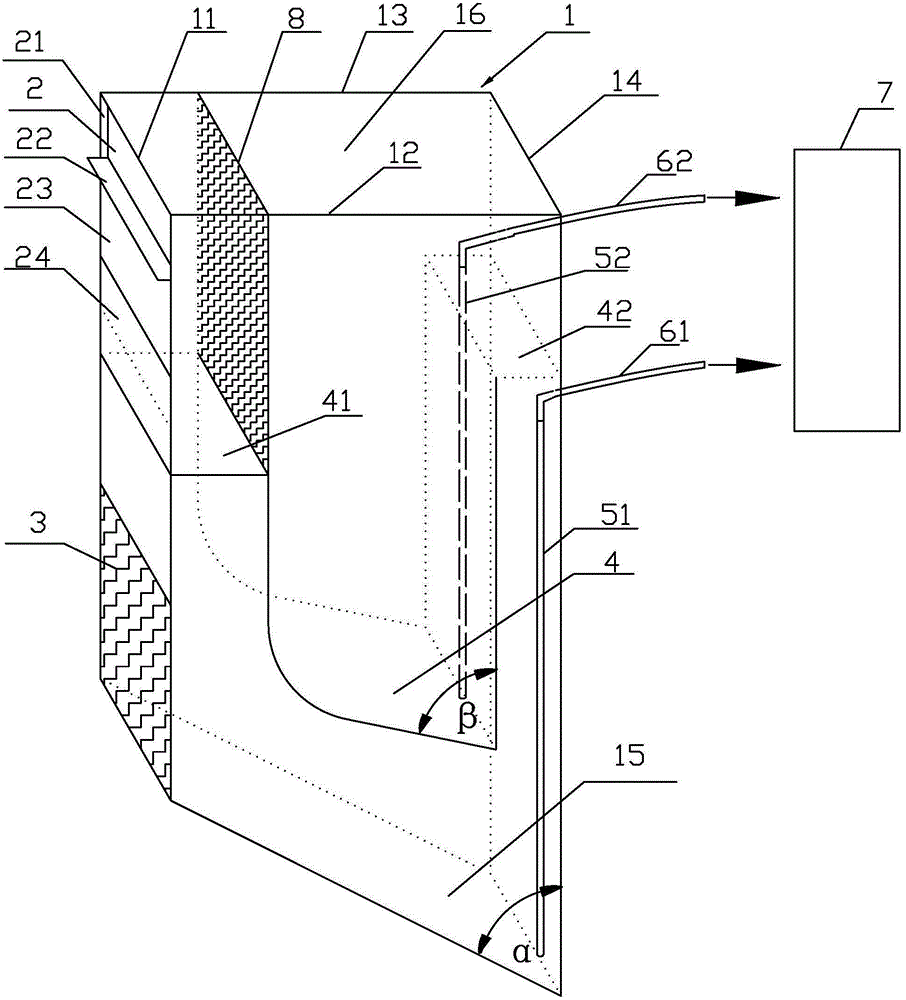

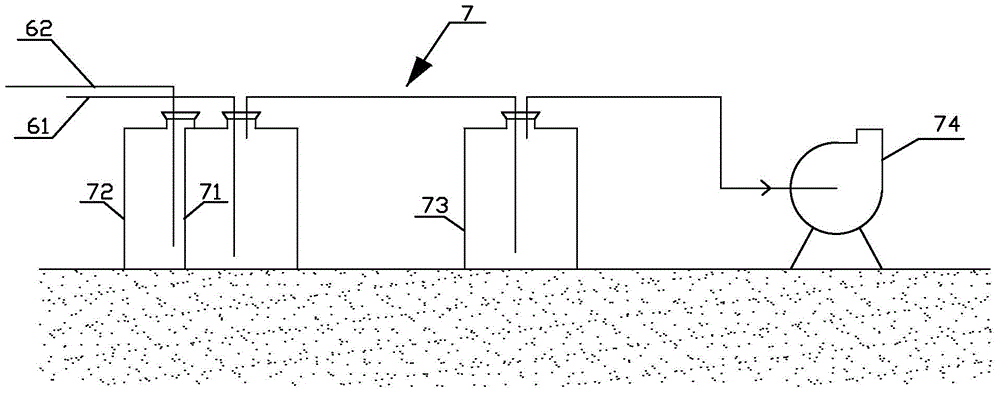

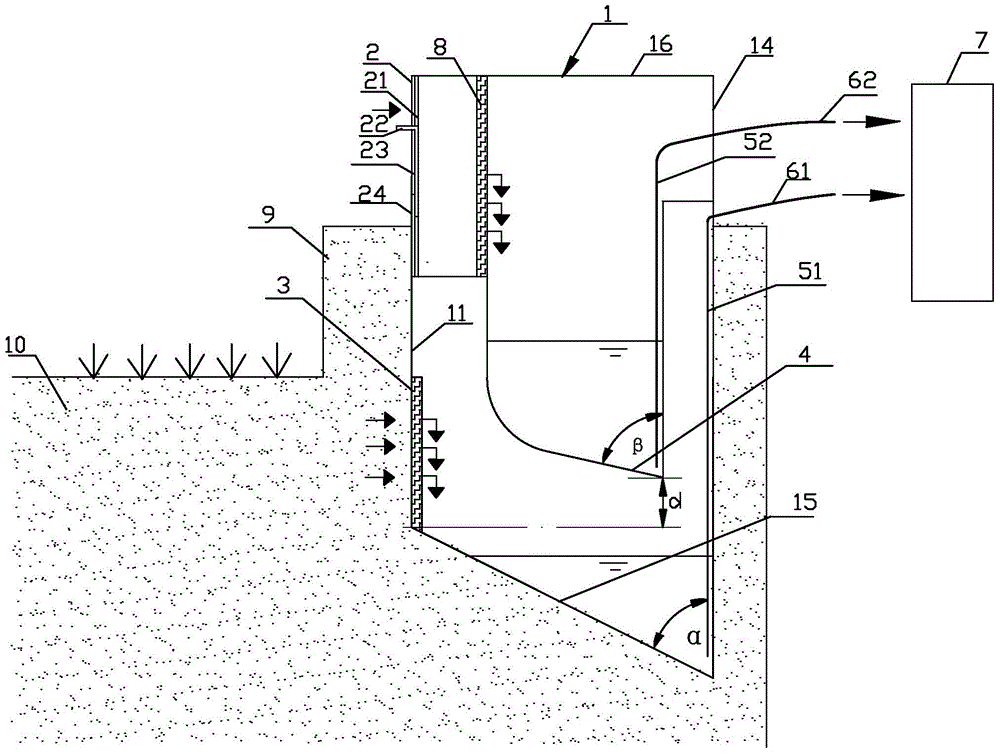

[0019] Figure 1 ~ Figure 3 It shows an integrated device for collecting paddy field side seepage and surface runoff and its application in paddy fields. The integrated device is characterized in that it includes a top sealed collection box 1 whose longitudinal section is a right-angled trapezoid. The bottom plate 15 is vertically inserted into the paddy field ridge soil 9, and its inclined bottom forms a side seepage liquid storage tank. The high end of the bottom plate 15 is connected to the liquid inlet side wall 11 of the box close to the paddy field side, and the low end of the bottom plate is connected to the box body away from it. The liquid outlet side wall 14 on the rice field side; the angle α at the lower end of the inclined tank bottom of the side seepage liquid storage tank is 30°-50°. A U-shaped groove plate 4 with a U-shaped longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com