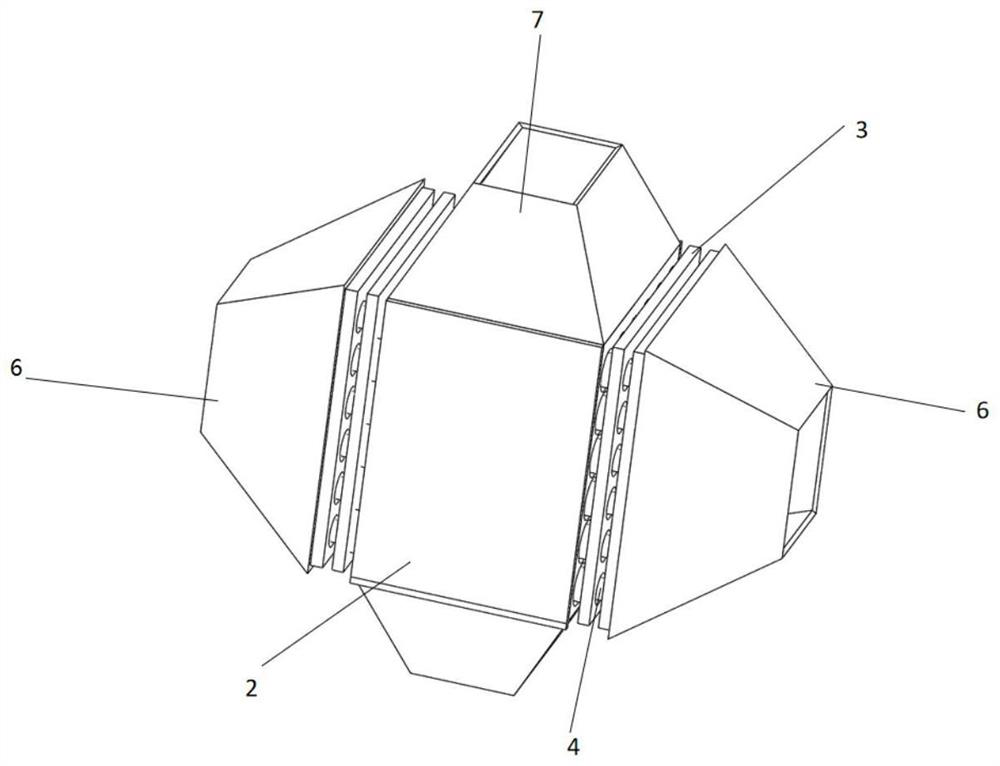

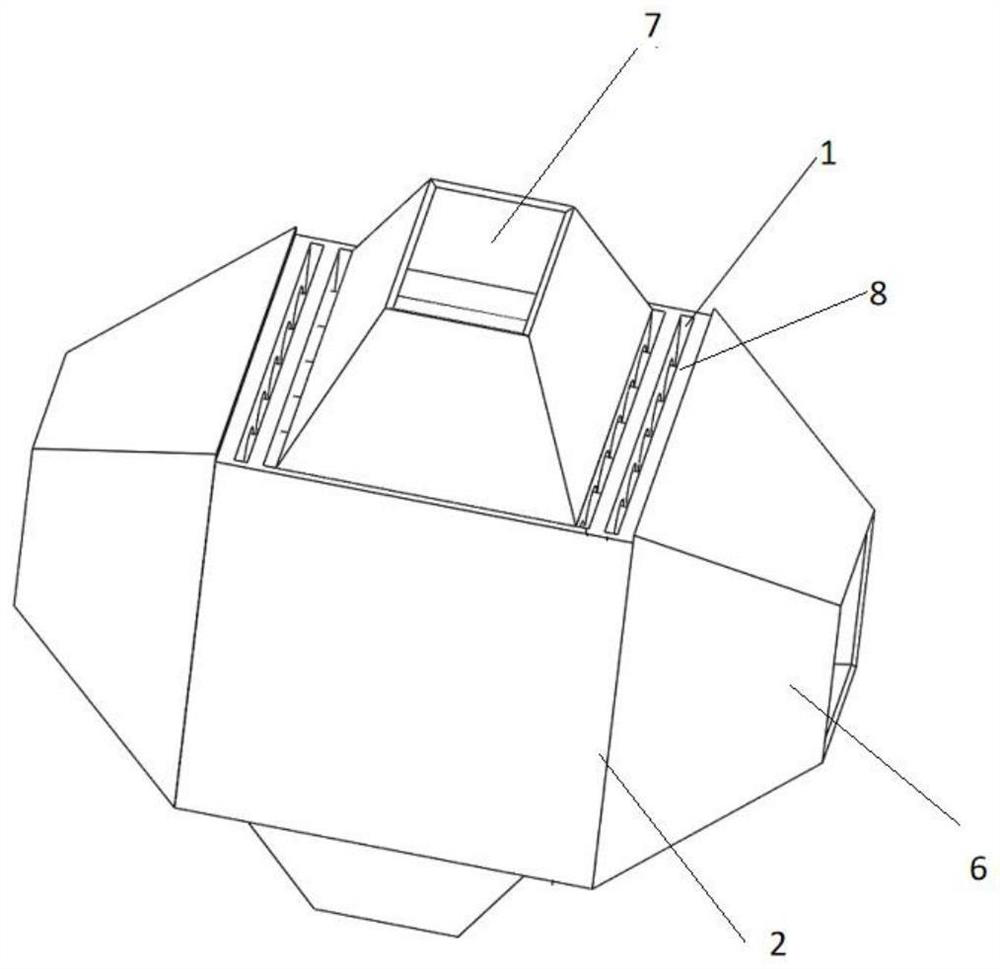

Multi-channel heat storage device and using method thereof

A heat storage device, multi-channel technology, applied in heat storage equipment, heat exchange equipment, heat exchanger types, etc., can solve problems such as pollution, and achieve the effects of avoiding mutual pollution, increasing heat recovery efficiency, and increasing heat storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

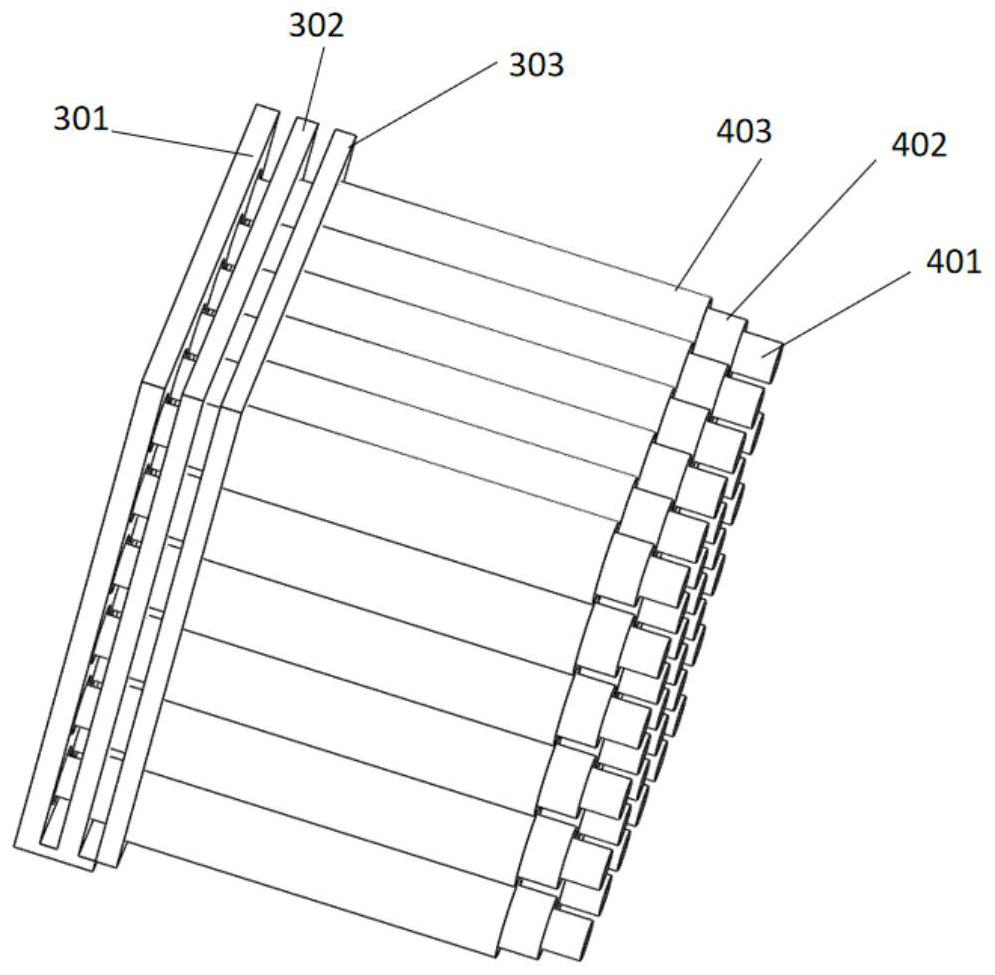

[0042] Let the first heat exchange medium flow into the first heat exchange medium circulation channel 9 inside the inner pipe body 401 through the through hole on the third orifice plate 301, and the inner pipe body 401 exchanges heat with the heat exchange medium, and then the first The other end of the heat exchange medium circulation passage 9 is discharged.

[0043] And / or, make the second heat exchange medium enter into the second heat exchange medium circulation path 10 along the through hole 1 between the third orifice plate 301 and the second orifice plate 302, and then pass through the second orifice plate The through hole on the 302 flows into the gap between the middle pipe body 402 and the inner pipe body 401; the middle pipe body 402 and the inner pipe body 401 exchange heat with the second heat exchange medium, and then from the other end of the second heat exchange medium circulation passage 10 discharge.

[0044] And / or, make the third heat exchange medium en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com