Method, system and equipment for testing pulse frequency of stepping motor

A technology of pulse frequency and stepping motor, which is applied in the direction of frequency measurement device, etc., can solve the problems of thermal printer core printing compression, easy to miss the resonance frequency area, and low test efficiency, so as to reduce manual intervention and judgment, and ensure good work Status, the effect of realizing intelligent testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Please refer to Image 6 , Embodiment 1 of the present invention is:

[0078] A kind of testing equipment of the pulse frequency of the stepper motor 6 in the thermal printer core of a POS machine, comprising a stepper motor 6, a drive circuit 7, a CPU and an audio acquisition circuit 9; the audio acquisition circuit 9 includes a sequentially connected MIC receiving circuit 91. Filter amplifier circuit 92 and AD sampling circuit 93;

[0079] The stepping motor 6 is connected to the driving circuit 7; the CPU is respectively connected to the driving circuit 7 and the audio acquisition circuit 9; the audio acquisition circuit 9 is arranged adjacent to the stepping motor 6.

Embodiment 2

[0080] Please refer to image 3 , on the basis of embodiment one, embodiment two of the present invention is:

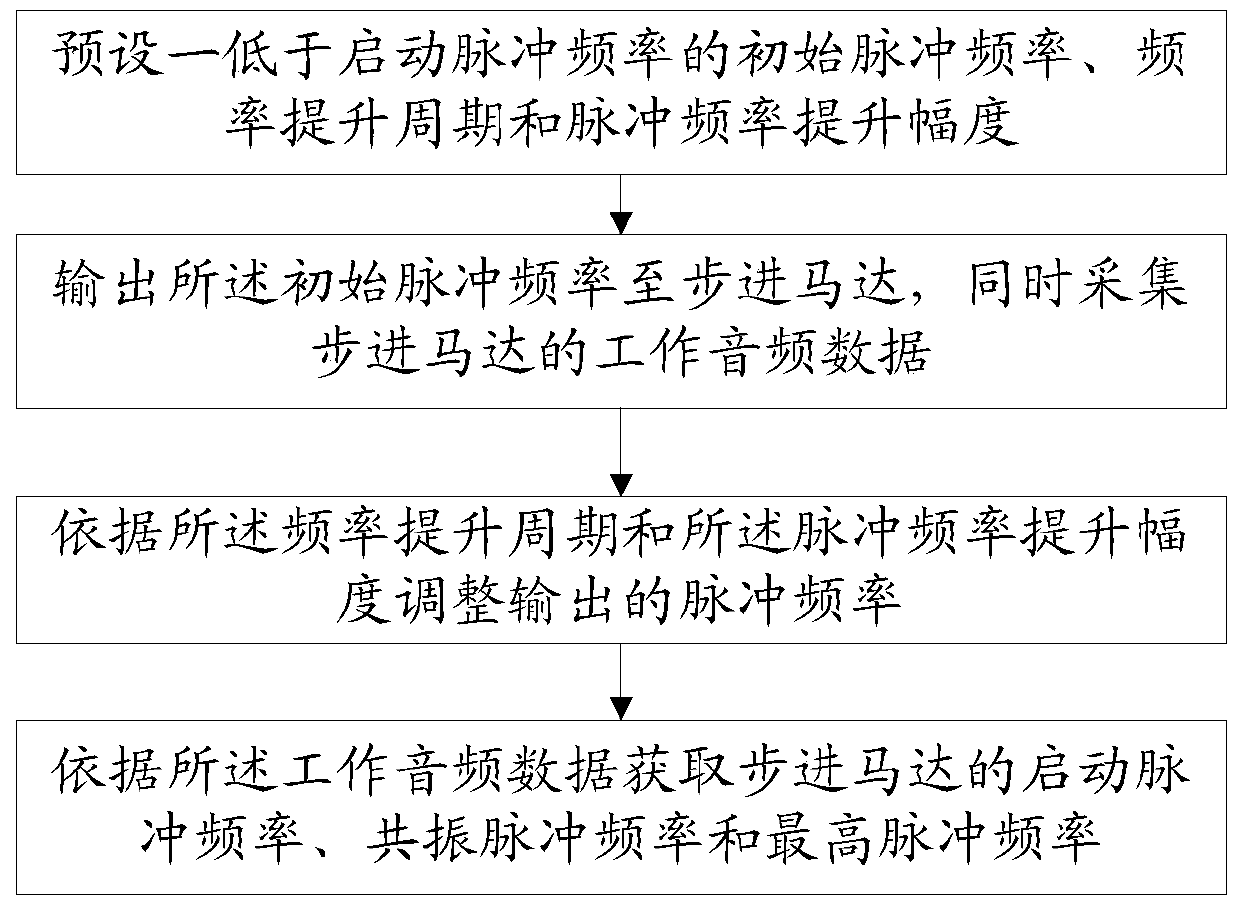

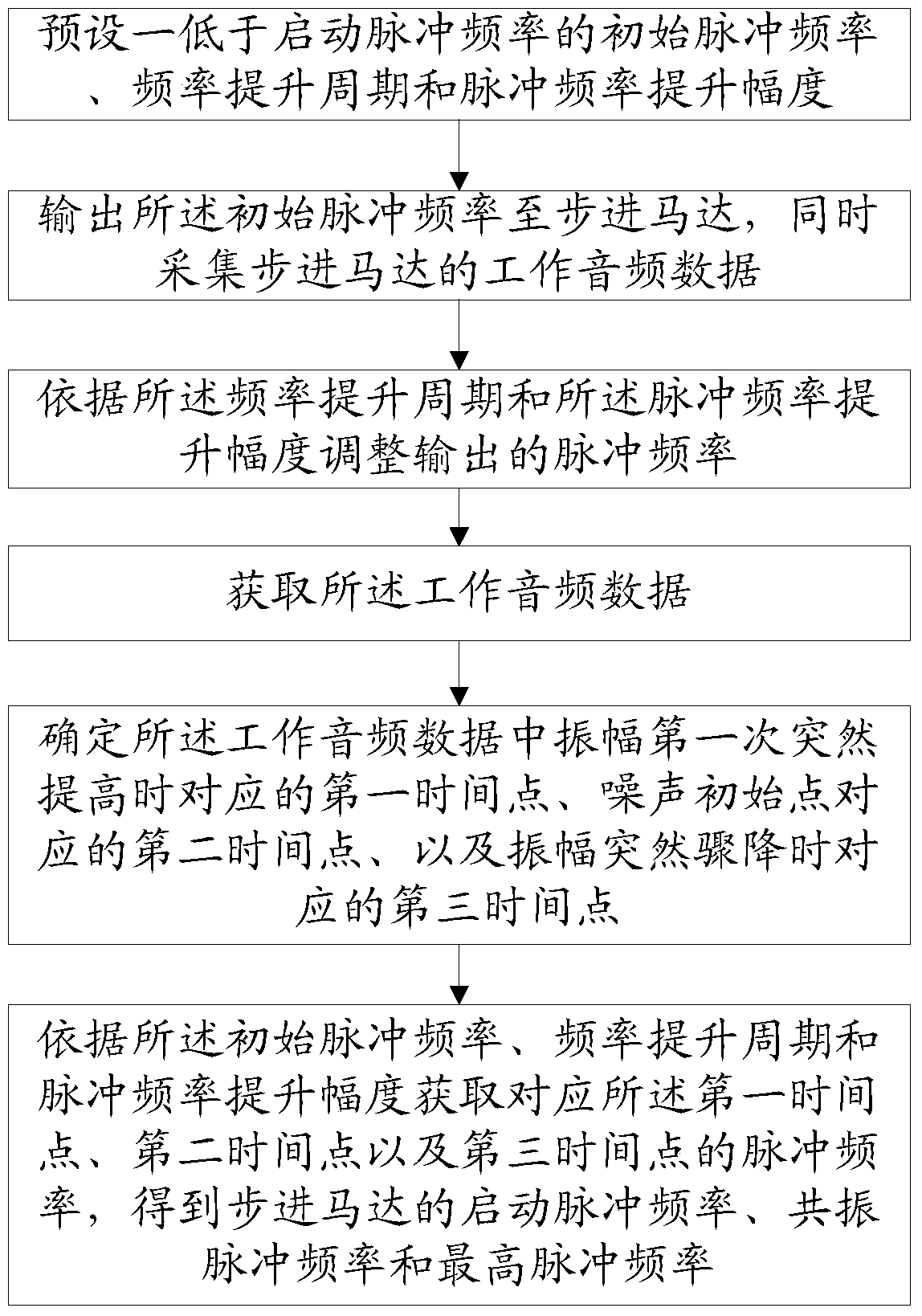

[0081] A method for testing the pulse frequency of a stepping motor 6, especially when the stepping motor 6 is used as an actuator of a thermal printing core of a POS machine; the specific testing process includes:

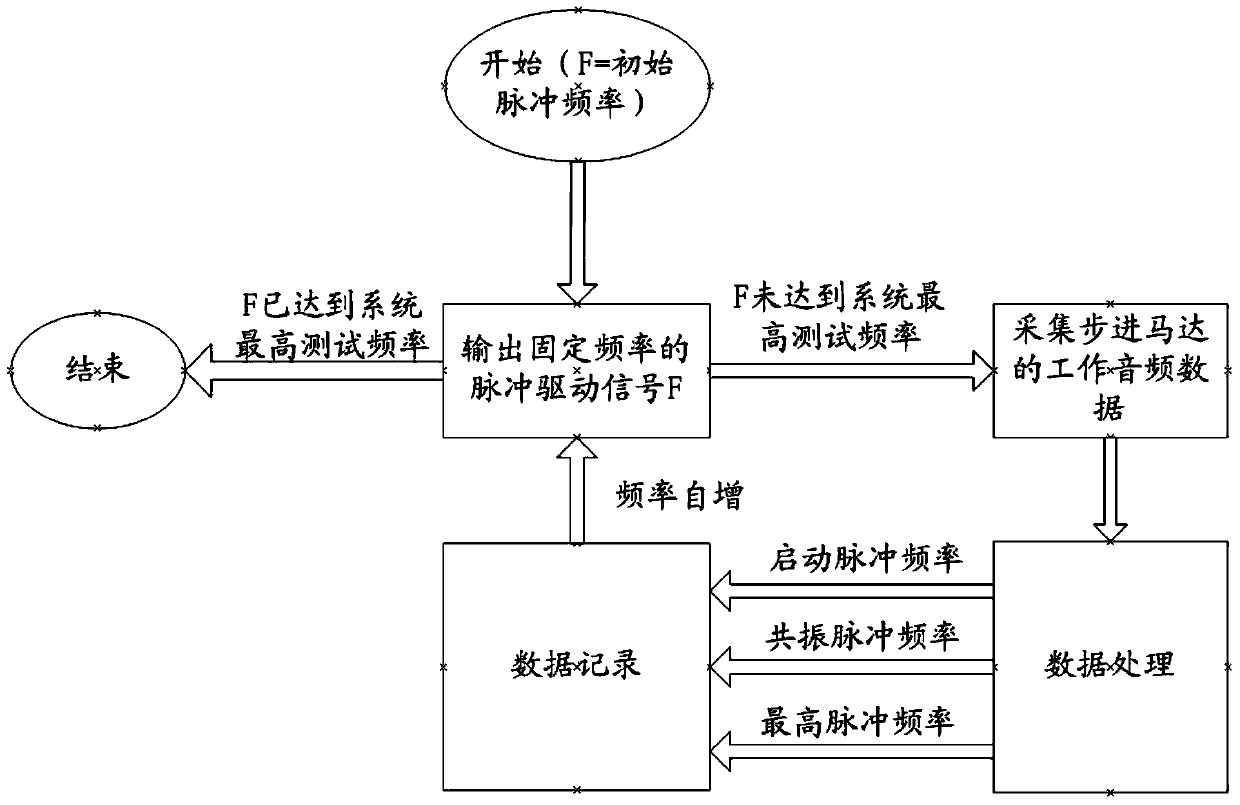

[0082] 1. Preset an initial pulse frequency F lower than the starting pulse frequency of the stepping motor 6, a frequency boost period T, a pulse frequency boost range D, and a maximum test frequency M; the above preset parameters F, T, D and M can be Flexible deployment according to measurement accuracy requirements;

[0083] 2. Start: the CPU controls the drive circuit 7 to output the initial pulse frequency F to the stepper motor 6; the audio acquisition circuit 9 synchronously collects the working audio data of the stepper motor 6 and sends it to the CPU;

[0084] 3. Every other frequency boost cycle T, increase the pulse frequency boost range D o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com