Filter element

A filter and filter element technology, which is applied in gravity filter, fixed filter element filter, filter separation, etc., can solve the problems of nozzle clogging and long service life in the movable section, and improve the overall pressure resistance, convenient processing, and structure cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

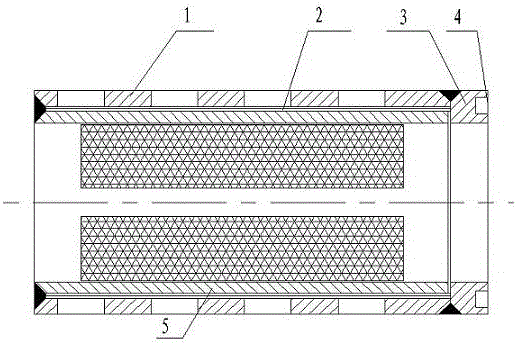

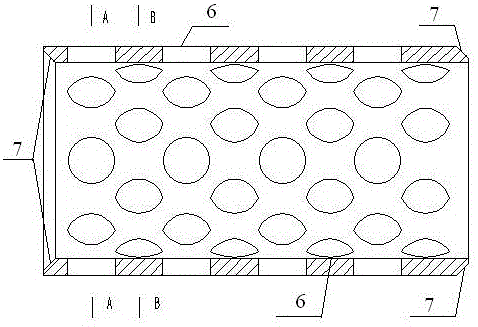

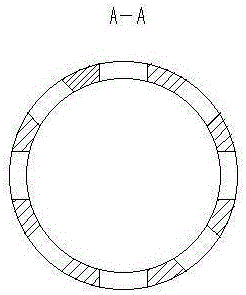

[0026] Such as figure 1 — Figure 8 As shown, a filter element includes an outer cover 1, an inner cover 5, a stainless steel sealing plate 3 and a stainless steel filter screen 2, and the surface roughness of the removed processing surface of the outer cover 1, the inner cover 5 and the stainless steel sealing plate 2 must not exceed the maximum More than 6.3 microns, with the inner sleeve 5 as the skeleton of the stainless steel filter screen 2, the length of the stainless steel filter screen 2 is consistent with the inner sleeve 5, but the inner diameter of the stainless steel filter screen 2 is slightly larger than the outer diameter of the inner sleeve, so the stainless steel filter screen 2 Put it on the inner sleeve 5, and then use the outer sleeve 1 to cover the stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com