Multiple effect integrated waste gas purification system

A waste gas treatment and purification device technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as fire risk, high investment and operating costs, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

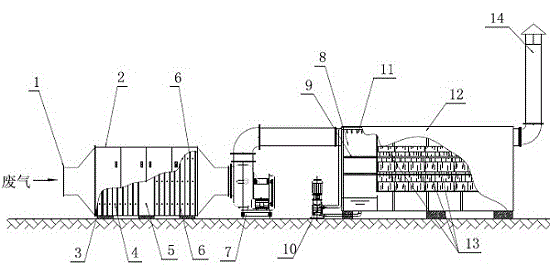

[0011] The invention includes an ozone+ultraviolet photocatalyst reaction stage (2), a nanosphere air purification stage (8), and a biological dripping filter stage (12), which are completed by two box devices. This system takes 20000m 3 / h as an example, in figure 1 Among them, the ozone + ultraviolet photocatalyst reactor is connected to the front air intake pipe through the flange (1), and two paint mist filters (3) are installed at the air intake end to remove most of the paint mist in the exhaust gas and prevent the paint mist from passing through. into the follow-up reaction device, resulting in clogging of the filter or reducing the brightness of the ultraviolet lamp. According to the concentration of paint mist in the exhaust gas, the paint mist filter needs to be replaced regularly. Exhaust gas passes through 16 photocatalyst filter screens (6) after removing a large amount of paint mist through the paint mist filter screen. In the compartment of the photocatalyst f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com