Clamping structure for circuit board welding

A clamping structure and circuit board technology, applied in the directions of printed circuits, auxiliary devices, welding equipment, etc., can solve the problems of increasing the circuit board process, increasing the work intensity of the operator, reducing the welding efficiency of the circuit board, etc., to improve the clamping effect. , the effect of moving up to stabilize and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

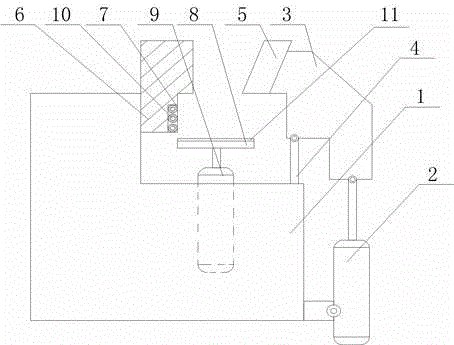

[0018] Such as figure 1 As shown, this embodiment includes a welding frame 1 and a hydraulic cylinder 2 fixed on the side wall of the welding frame 1. A baffle plate 6, a support rod 4 and a cylinder 9 are fixed on the welding frame 1. On the output end of the hydraulic cylinder 2 The movable block 3 is hinged, and the top of the support rod 4 is hinged with the bottom surface of the movable block 3, and the chuck 5 facing the baffle plate 6 is fixed on the side wall of the movable block 3, and the output end of the cylinder 9 A top plate 8 is fixed on it, the baffle 6 is L-shaped, and the vertical part of the baffle 6 is fixed on the welding frame 1, the horizontal part of the baffle 6 faces the chuck 5, and on the There is a rectangular groove 7 with an open end on the side wall of the vertical part of 6 close to the chuck 5, and a plurality of rollers 10 parallel to the top plate 8 are rotated in the rectangular groove 7. One of the top plates The side ends are aligned wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com