Heat-preserving pulp for self heat-preserving building block

A technology for self-insulation blocks and thermal insulation slurry, applied in the field of thermal insulation slurry, can solve the problems of difficulty in ensuring thermal insulation effect and service life, inability to combine blocks and thermal insulation materials well, etc., to achieve fire performance without hidden dangers, density Lightweight, high-capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical contents not mentioned below can adopt or learn from the prior art.

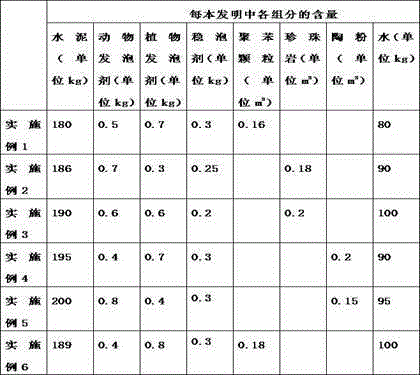

[0020] The present invention lists several embodiments in tabular form:

[0021]

[0022] The present invention can have following preparation method:

[0023] The raw materials are mixed, stirred and compounded, and injected into the inner hole of the block using grouting equipment. The inner hole of the rigid block should be immediately sealed and covered by the thermal insulation slurry to achieve vacuum foaming and expansion to prevent collapse.

[0024] After the block is grouted and sealed, it enters the maintenance cargo factory for maintenance to meet the quality standard.

[0025] The thermal insulation slurry is filled in the hole of the block, and the slurry has certain bonding and expansion properties, and then condenses into one body without gaps.

[0026] The thickness of the thermal insulation slurry pouring body can reach three quarters of the thickness of the block;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com