Finished stretching and straightening method of titanium belt for plate heat exchanger

A technology for plate heat exchangers and titanium strips, which is applied in the field of finished product tensioning and straightening of titanium strips for plate heat exchangers, which can solve the problems of large metal loss, low yield, and long time consumption, and achieve the effect of smooth stamping and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

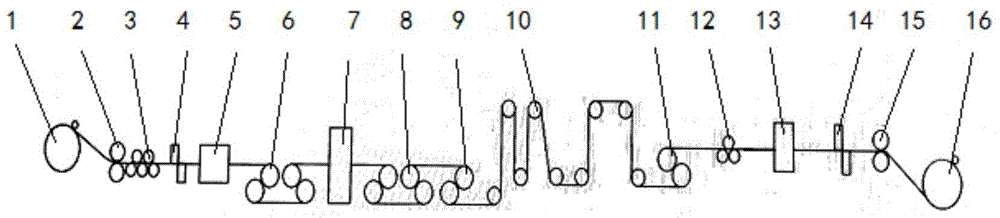

Method used

Image

Examples

Embodiment 1

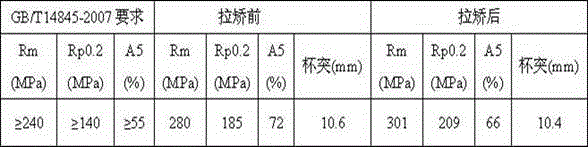

[0029] Example 1: Tension-leveling process of pure titanium strips for plate heat exchangers with a thickness of 0.5 mm and a width of 1180 mm. See Table 1 for the specific process parameters and the comparison before and after tension leveling, and see Table 2 for the comparison of mechanical properties before and after tension leveling.

[0030] Table 1 The specific parameters of the 0.5mm plate replaced with titanium belt tension leveling and the comparison before and after tension leveling

[0031]

[0032] Table 2 Comparison of mechanical properties at room temperature before and after the 0.5mm plate is replaced with titanium belt for tension leveling

[0033]

[0034] When the tension, reduction and elongation are matched with each other according to the parameter values listed in Table 1, the 0.5mm plate can be replaced with pure titanium strip. The crown height of the original 10mm is straightened to 0~2mm, and the width is reduced 3mm. It can be seen from T...

Embodiment 2

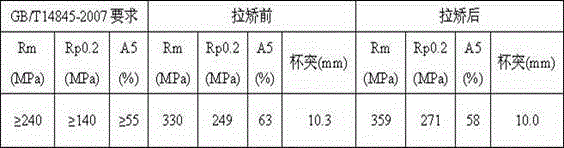

[0035] Embodiment 2: Tension and straightening process of pure titanium strips for plate heat exchangers with a thickness of 0.8 mm and a width of 1080 mm. The specific process parameters and the comparison before and after tension leveling are shown in Table 3. The comparison of mechanical properties at room temperature before and after tension leveling is shown in Table 4.

[0036] Table 3 The specific parameters of the 0.8mm plate replaced with titanium belt for tension leveling and the comparison before and after tension leveling

[0037]

[0038] Table 4 Comparison of mechanical properties at room temperature before and after the 0.8mm plate is replaced with titanium belt for tension leveling

[0039]

[0040] When the tension, reduction and elongation match each other according to the parameter values listed in Table 3, the arch height of the 0.8mm plate can be replaced with pure titanium strip from the original 12mm to 0~4mm, and the width is reduced at the sam...

Embodiment 3

[0041] Embodiment 3: Tension-leveling process of pure titanium strips for plate heat exchangers with a thickness of 1.0mm and a width of 1080mm. The specific process parameters and the comparison before and after tension leveling are shown in Table 5. The comparison of mechanical properties at room temperature before and after tension leveling is shown in Table 6.

[0042] Table 5 The specific parameters of the 1.0mm plate replaced with titanium belt for stretching and straightening and the comparison before and after stretching and straightening

[0043]

[0044] Table 6 Comparison of mechanical properties at room temperature before and after the 1.0mm plate is replaced with titanium belt for tension leveling

[0045]

[0046] When the tension, reduction and elongation match each other according to the parameter values listed in Table 5, the arch height of the 1.0mm plate can be replaced with pure titanium strip from the original 12mm to 0~5mm, and the width is reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com