A connection device and connection method for a marine spud leg and a spud shoe

A connection device and connection method technology, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve problems such as difficult maintenance, non-disassembly, easy cracks, etc., to achieve convenient disassembly, maintenance and replacement, convenient and reliable fixed installation, Easy to find and locate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

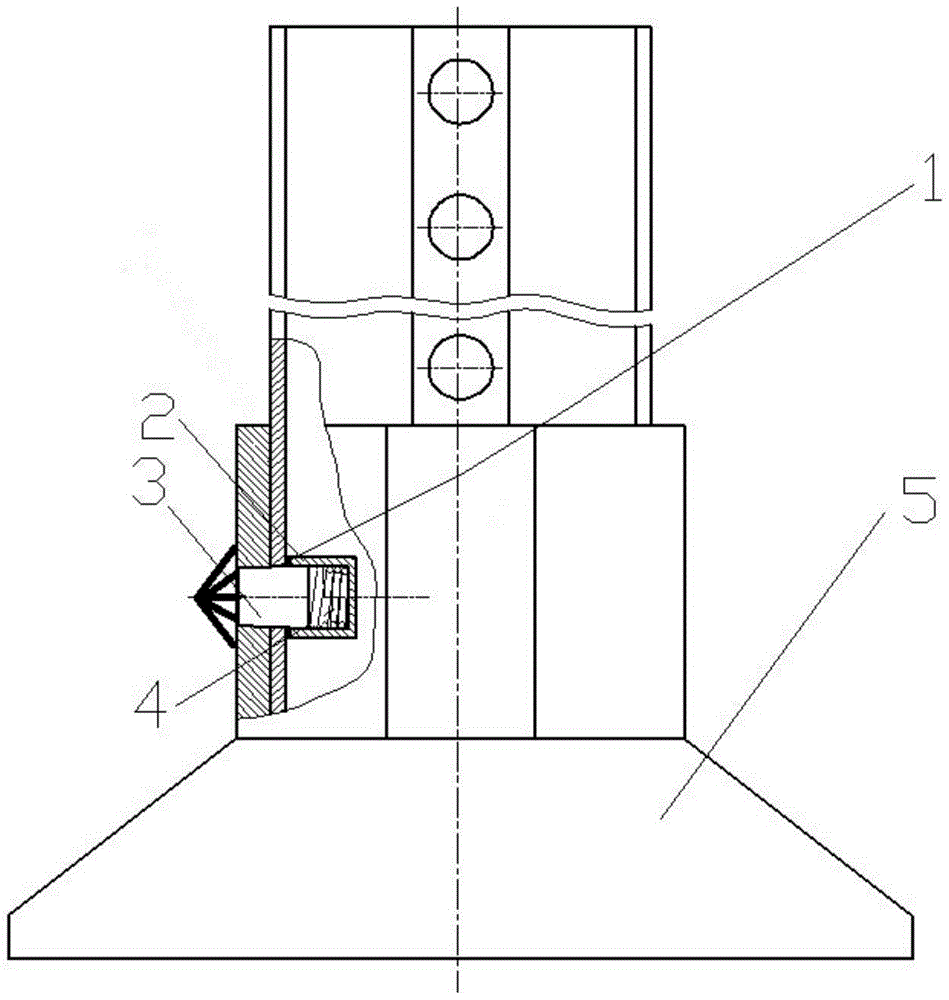

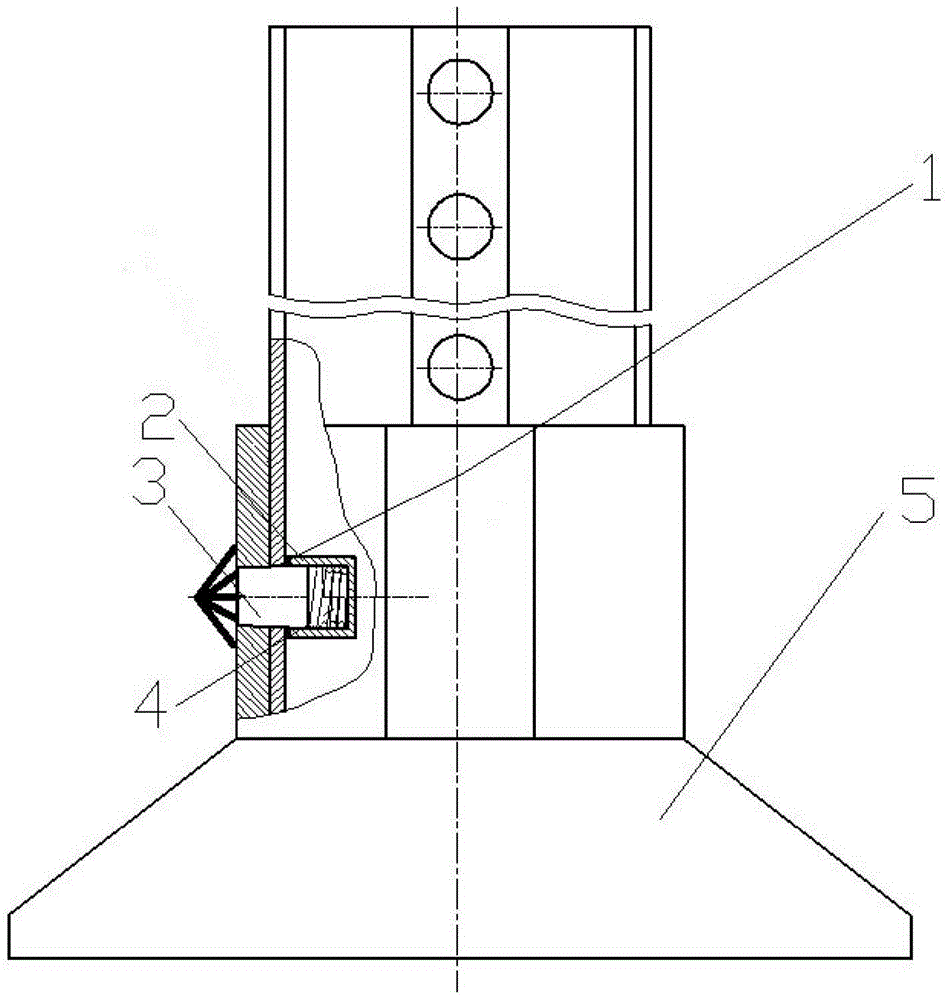

[0015] Example as figure 1 As shown, a connection device for a marine spud leg and a spud can, the connection device includes a spud leg 1 and a spud can 5, the spud leg 1 is inserted into the guide groove of the spud can 5, and the spud leg 1 Including at least one pin hole, the inner side of the pin hole of the pile leg 1 includes at least one support sleeve 2; the support sleeve 2 has a pressure sensor, a compression spring 4, a connecting pin 3 and a manipulator; the manipulator is on the support The sleeve 2 is in a gripping shape; the spud shoe 5 includes at least one spud shoe hole, and the position of the spud shoe hole corresponds to the position of the support sleeve 2; the compression spring 4 abuts against the pressure sensor, so One end of the connecting pin 3 abuts against the compression spring 4, and the other end abuts against the manipulator; when the connecting pin 3 is inserted into the pin hole and the spud can hole, the pressure sensor detects that the pr...

Embodiment 2

[0016] Example two such as figure 1 As shown, a connection method between a marine spud leg and a spud shoe: the support sleeve 2 is arranged inside the pin hole of the spud leg 1; the pressure sensor, the compression spring 4, the connecting pin 3 and the manipulator are arranged on the support sleeve 2 Inside: the pressure sensor is arranged inside the support sleeve 2; one end of the compression spring 4 abuts the pressure sensor, and the other end abuts the connecting pin 3; the other end of the connecting pin 3 abuts The manipulator; the position of the manipulator close to the pin hole; the manipulator is in a grip on the support sleeve 2; the spud shoe 5 is opened at the corresponding connection position of the support sleeve 2 to form a spud shoe hole ; use a lifting device to lift the spud leg 1 to connect the spud leg 1 and the spud can 5, the spud leg 1 slides down along the guide groove of the spud can 5, and the process of sliding down The compression spring 4 co...

Embodiment 3

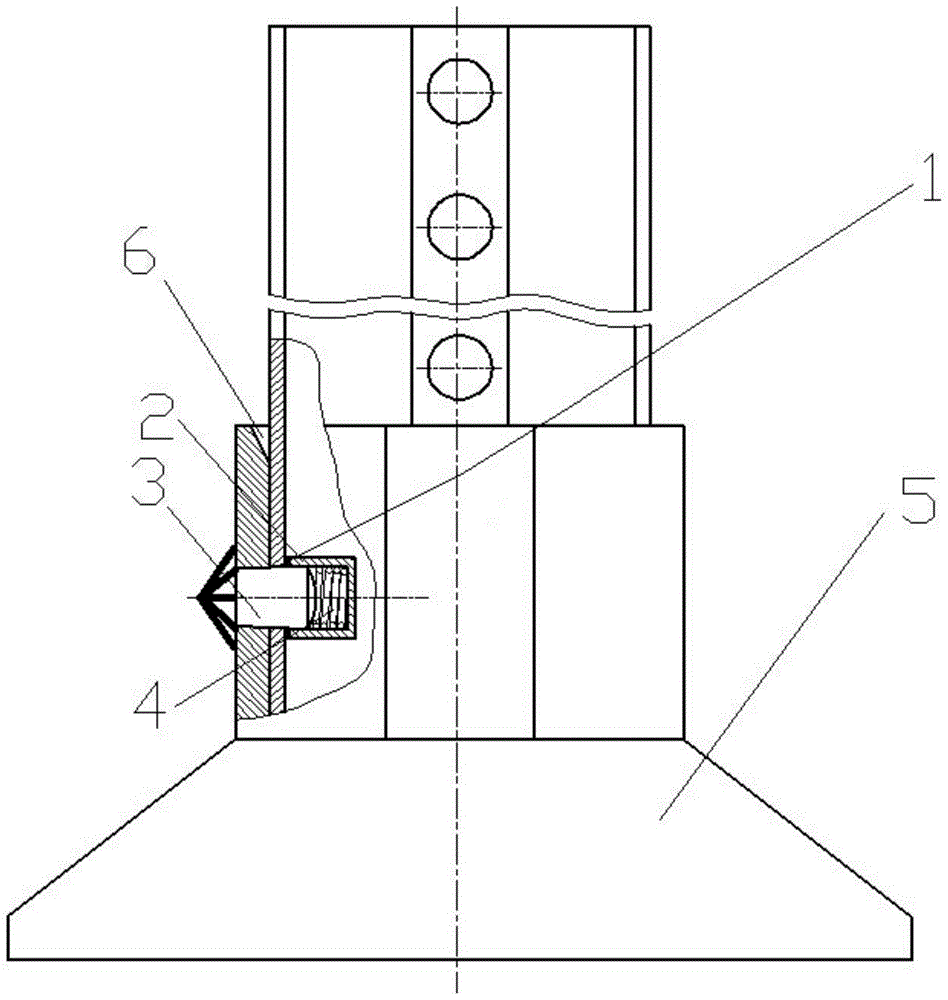

[0017] Embodiment three such as figure 2 As shown, a connection device for a marine spud leg and a spud can, the connection device includes a spud leg 1 and a spud can 5, the spud leg 1 is inserted into the guide groove of the spud can 5, and the spud leg 1 Including at least one pin hole, the inner side of the pin hole of the pile leg 1 includes at least one support sleeve 2; the support sleeve 2 has a pressure sensor, a compression spring 4, a connecting pin 3 and a manipulator; the manipulator is on the support The sleeve 2 is in a gripping shape; the spud shoe 5 includes at least one spud shoe hole, and the position of the spud shoe hole corresponds to the position of the support sleeve 2; the compression spring 4 abuts against the pressure sensor, so One end of the connecting pin 3 abuts against the compression spring 4, and the other end abuts against the manipulator; when the connecting pin 3 is inserted into the pin hole and the spud can hole, the pressure sensor dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com