Connecting method for bamboo wood prefabricated wallboards

A technology of prefabricated wall panels and connection method, applied in the direction of walls, building materials, building components, etc., can solve the problems of poor integrity, low construction efficiency, easy corrosion of connecting components, etc., and achieve the effect of simple process, low cost, and avoidance of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

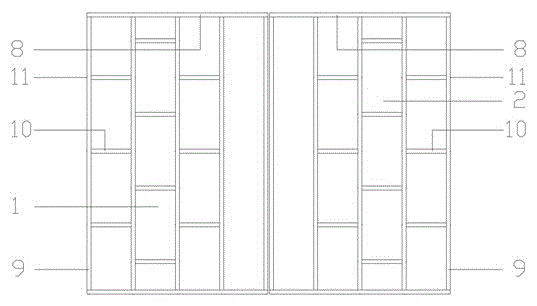

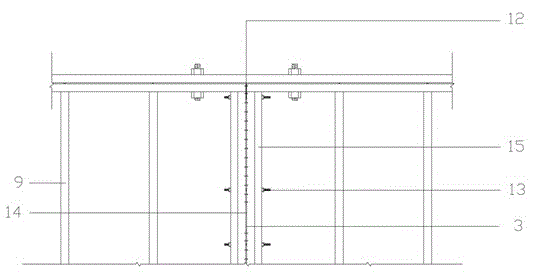

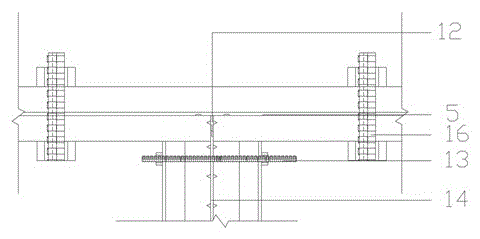

[0030] Embodiment 1: as Figure 1-7 As shown, a connection method for bamboo and wood prefabricated wallboards, including bamboo and wood prefabricated wallboard skeleton I1, bamboo and wood prefabricated wallboard skeleton II2, bamboo and wood prefabricated wallboard joints 3, top beams 4, top Beam steel plate support bar 5, ground beam steel plate support bar 6, and reinforced concrete strip foundation 7; among them, the bamboo and wood prefabricated wall panel skeleton I1 and the bamboo and wood prefabricated wall panel skeleton II2 are composed of a horizontal support frame 8, a longitudinal support frame 9, and a horizontal support bar 10 are combined and connected by steel nails 11, and a row of horizontal support bars 10 near the inner side are not assembled and nailed first; the joint joint 3 of bamboo and wood prefabricated wall panels is composed of double-sided tooth plates 12, wall-through bolts 13, adhesive glue 14, The reaction force distribution steel beam 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com