Separation device for purifying petroleum drilling fluid

A separation device and oil drilling technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve the problems of poor screening efficiency and unsatisfactory screening effect, and achieve the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

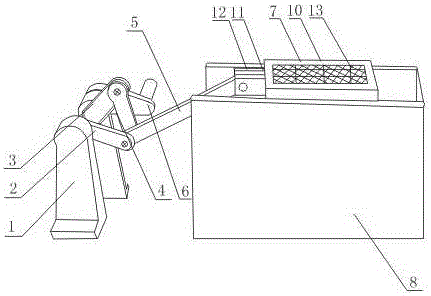

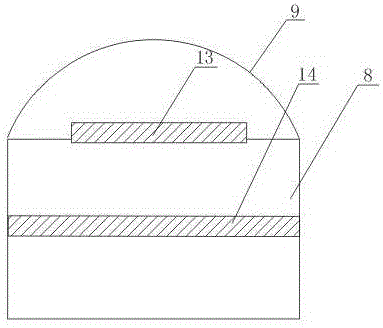

[0020] Such as figure 1 , figure 2 As shown, a separation device for purifying oil drilling fluid includes two parallel pillars 1, connecting rod A2, connecting rod B3, and connecting rod C4 in a triangular structure formed by sequentially hinged head to tail, and also includes connecting rods B3, The pull rod 5 between the connecting rods C4 and one end of which is hinged with the connecting rod B3 and the connecting rod C4 respectively, also includes a rotating disk 6 fixed on the side of the pillar 1; the rotating disk 6, the pillar 1, the connecting rod A2, and the connecting rod B3 are connected through a rotating shaft; It also includes a sieve tray 7 hinged to the other end of the pull rod 5, and a sieve box 8 arranged below the sieve tray 7. The sieve box 8 is a cavity structure with an upper surface and a side opening. Both sides of the upper surface; also includes a protective cover 9 arranged on the upper end of the screen box 8, and the opening of the lower end o...

Embodiment 2

[0023] In this embodiment, on the basis of Embodiment 1, an observation port is opened on the protective cover 9 .

[0024] The observation port arranged on the protective cover 9 is convenient for the staff to observe the working dynamics of the sieve tray 7, and repair it in time when the sieve tray 7 breaks down.

Embodiment 3

[0026] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the sieve tray 7 includes a sieve body 10, a connecting section 11 fixed at one end of the sieve body 10, and the connecting section 11 is composed of two connecting rods 12 arranged parallel to each other. , one end of the connecting rod 12 is fixed on the screen body 10; the tie rod 5 is hinged in two connecting rods 12 arranged parallel to each other; the screen body 10 is a cuboid cavity structure with upper and lower openings, and also includes a The first screen 13 in the cavity.

[0027] The pull rod 5 in this embodiment is hinged in two connecting rods 11 arranged parallel to each other, so that the movement of the pull rod 5 can drive the screen tray 7 to move left and right along the upper surface of the screen box 8 . The first screen 13 arranged in the screen body 10 plays a role of preliminary filtering of petroleum mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com