A vehicle exhaust gas purification treatment system and treatment method based on ultrasonic control

A technology for automobile exhaust and purification treatment, which is applied in the direction of exhaust devices, air quality improvement, machines/engines, etc., and can solve the problems of reduced purification efficiency of three-way catalytic converters, so as to improve the interaction effect, improve the effect, and improve the uniformity of spraying degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

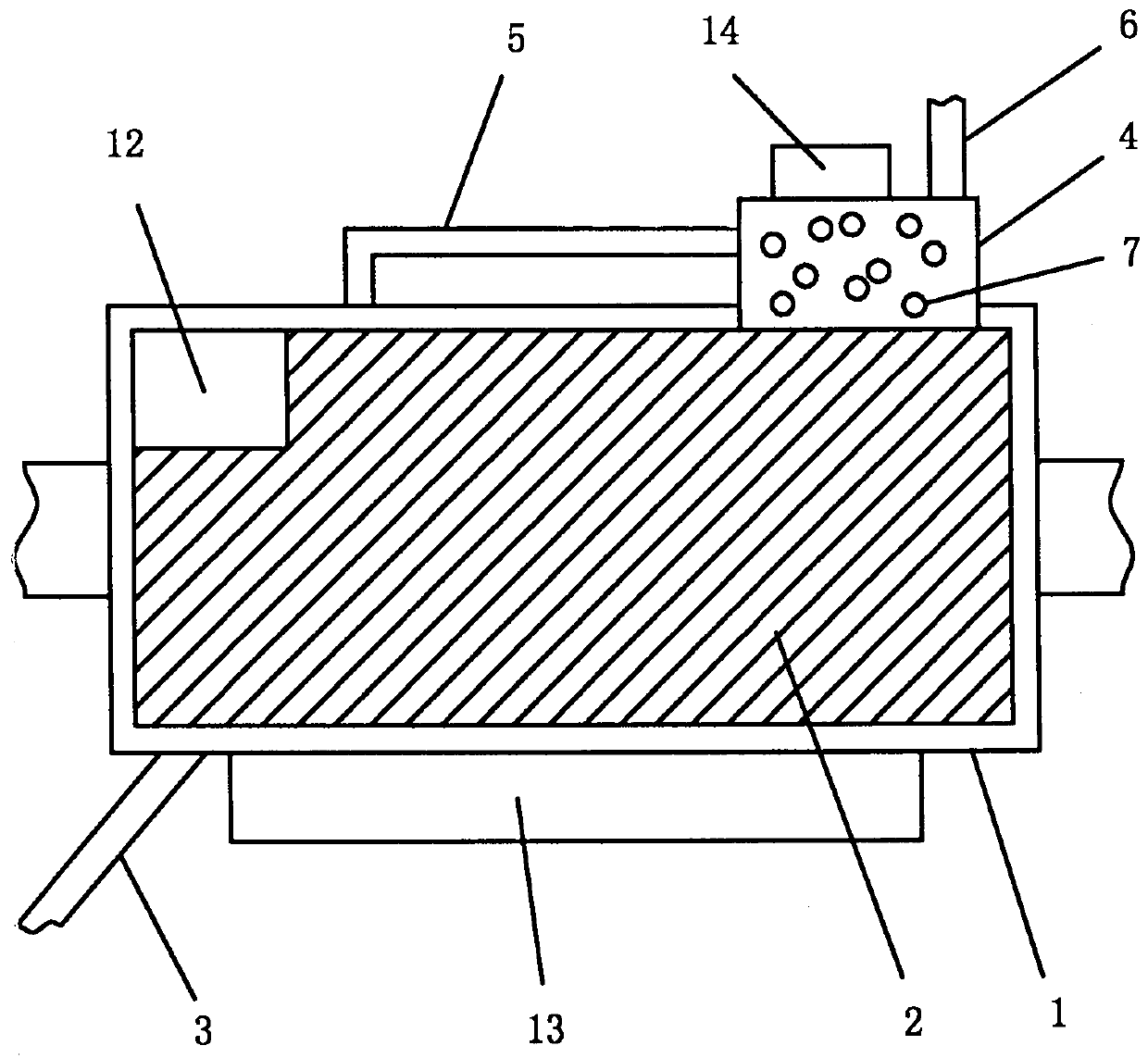

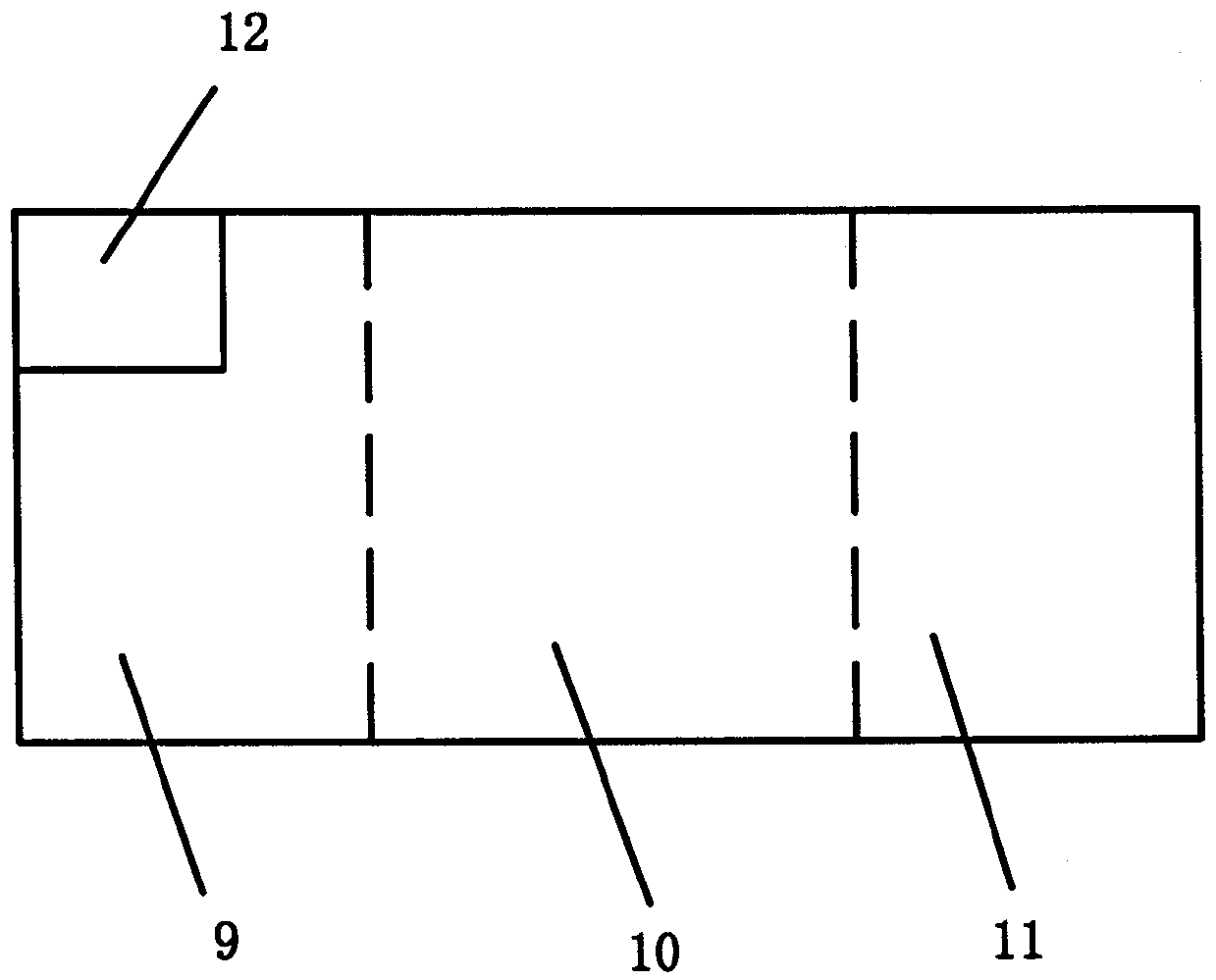

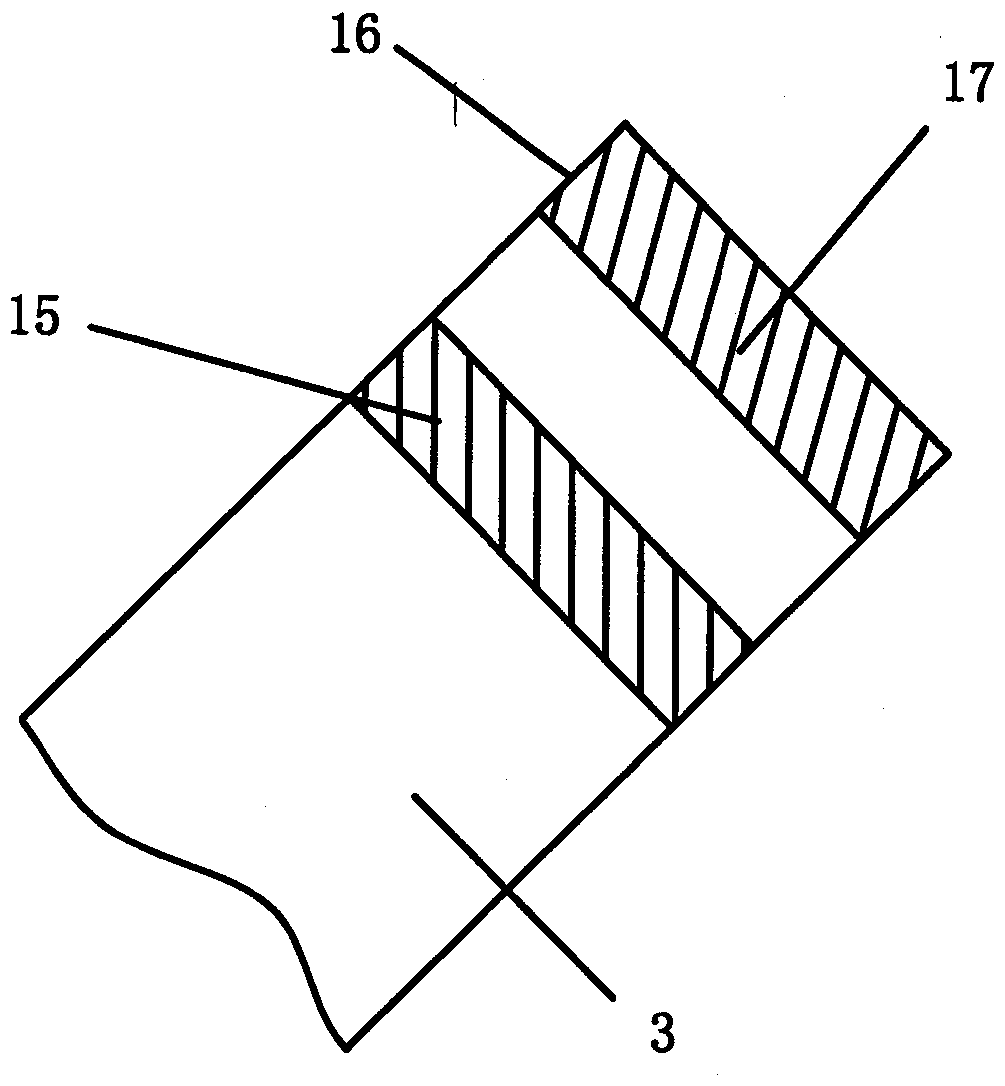

[0027] refer to Figure 1-6 , a specific embodiment of the present invention includes a three-way catalytic converter housing 1, a mesh plate 2 is arranged inside the three-way catalytic converter housing 1, and a first bypass is provided below the air intake end of the three-way catalytic converter housing 1. Road injection port 3, a cleaning chamber 4 is arranged above the air outlet end of the three-way catalytic converter housing 1, and the cleaning chamber 4 is connected to the top of the intake end of the three-way catalytic converter housing 1 through a return pipe 5, and the cleaning chamber 4 The top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com