Differential planetary reducer

A planetary reducer and planetary gear technology, applied in the differential transmission, transmission, transmission parts and other directions, can solve the problems of poor craftsmanship, difficult manufacturing and installation, reduce power density, solve poor craftsmanship, and avoid machining Assembling difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

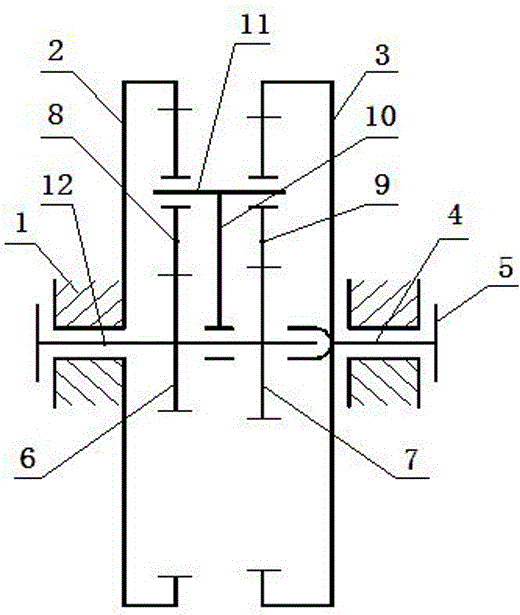

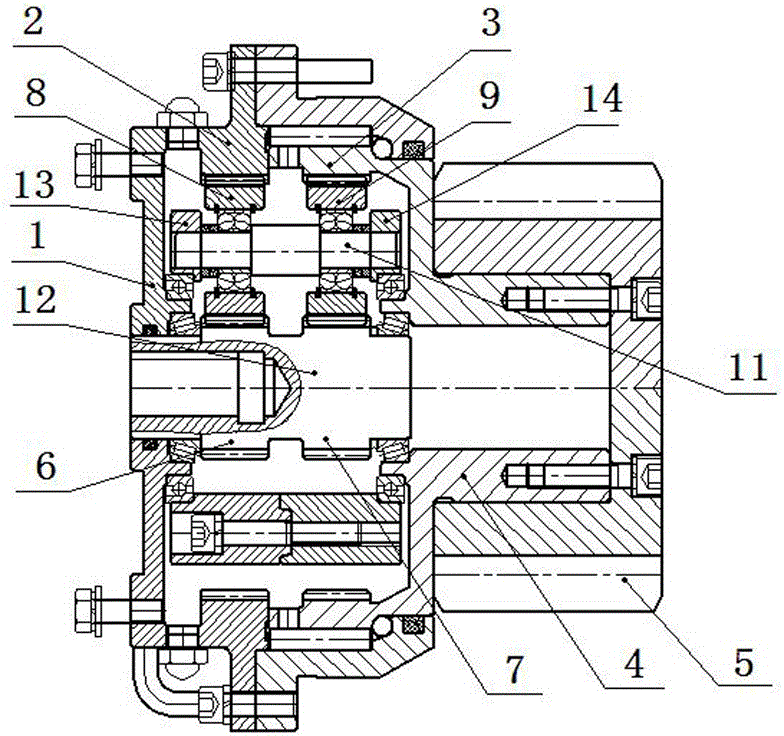

[0022] Such as figure 1 , figure 2 Shown: a differential planetary gear reducer (Differential planetary gear reducer, English abbreviation DPG) includes a base 1, a primary ring gear 2, a secondary ring gear 3, an input shaft 12, an output shaft 4, a center wheel, Planetary gear and planetary carrier 10; the center wheel is divided into a primary center wheel 6 and a secondary center wheel 7, which are respectively fixed on the input shaft 12; the planetary wheel is divided into a primary planetary wheel 8 and a secondary planetary wheel 9 , the first-stage planetary gear 8 meshes with the first-stage sun gear 6 and the first-stage ring gear 2 simultaneously to form a first-stage reduction system; Simultaneous meshing constitutes a two-stage reduction system; the two-stage ring gear 3 is fixedly connected to the output shaft 4 . There are three primary planetary gears 8 in the primary reduction system and three secondary planetary gears 9 in the secondary reduction system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com