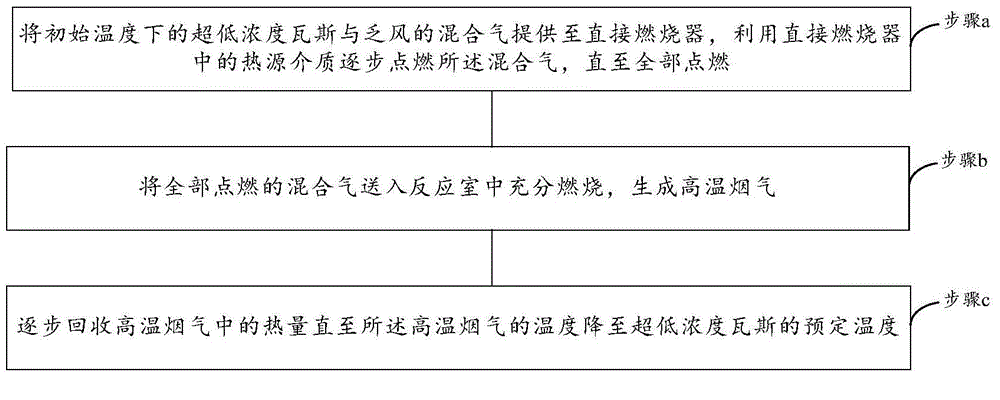

Ultra-low-concentration gas combustion method and system

A technology of ultra-low concentration and combustion method, applied in combustion method, combustion type, incinerator, etc., can solve problems such as low gas heat extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

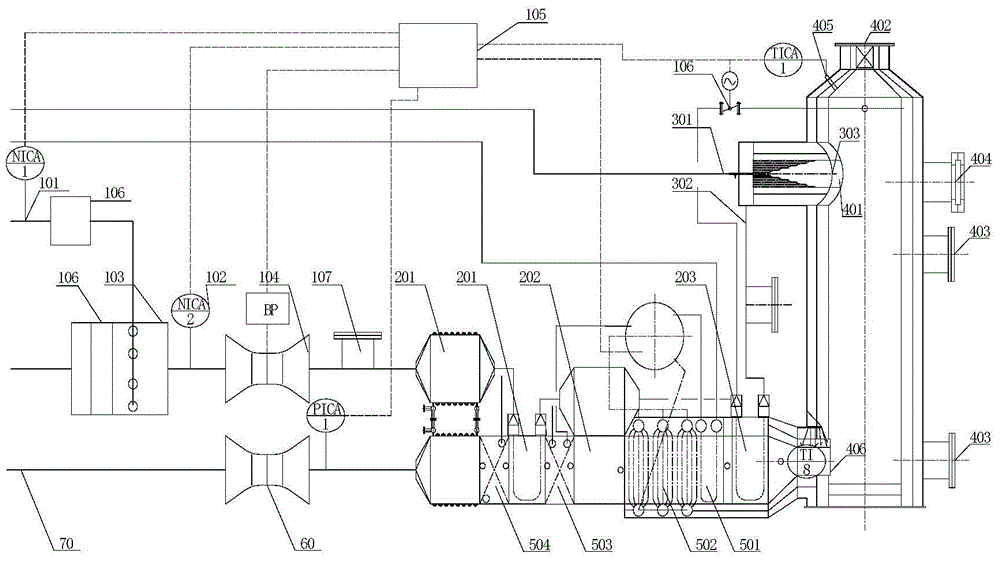

[0080] Such as figure 2 As shown, the ultra-low concentration gas and exhaust air enter the system through the ultra-low concentration gas source pipeline and mine exhaust gas pipeline respectively, and the ultra-low concentration is detected by the first gas concentration detector 101 installed on the ultra-low concentration gas source pipeline. Whether the gas concentration is within the set allowable fluctuation range, and it is regulated through the valve on the ultra-low concentration gas source pipeline; after that, the ultra-low concentration gas and exhaust air are mixed evenly in the mixing device 103, and set on the inlet pipeline by the blower 104 The second gas concentration detector 102 detects the concentration of ultra-low concentration gas in the mixed gas, and adjusts the exhaust air volume through the blower 104 to control the concentration of ultra-low concentration gas in the mixed gas to three times below the explosion limit at the corresponding initial te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com